Modern AG 10' Offset Flex Predator User Manual

Page 66

66 - 10’ Offset Predatorrr

MAintenAnce section

sLiP cLutcHes

a slip clutch is incorporated in the PtO driveline. It is designed to slip, absorb the shock load, and

protect the driveline. Clutch torque setting is factory set. If clutch slips excessively, check friction

discs for excessive wear. to adjust clutch, first check length of springs assembled on clutch. Length

should be 1 1/8 (28.5 mm). If not, adjust length of bolt to obtain proper spring length. If additional

adjustments is required, tighten each bolt 1/2 turn. nOte: DO nOt tighten spring bolts over 1/2

turn at any adjustment. excessive tightening can cause clutch to become frozen and not slip which

could cause damage to tractor PtO, drivelines, or gearbox.

avoid over heating of clutches caused by too long frequent slipping of the clutch since this can

damage the friction plates and clutch parts. WHen checking slip clutch for overheating, do not

touch with hand. Clutch could be extremely hot and cause severe burn.

SEASONAL cLUTcH MAINTENANcE

It is important that the clutches slip when an obstacle or load heavier than the clutch setting is

encountered. Before using the cutter each season, use the following procedure to make sure the

clutch will slip and give the overload protection required.

1. Loosen spring nut until the sprig is free, and then retighten approximately one turn.

2. attach machine to tractor, set engine at approximately half throttle and quickly engage PtO.

the procedure will break clutch facings loose and allow the proper torque to be maintained.

3. Return the nuts and bolts to their original position of 1 1/8” compressed spring length for 540

RPm or 1 3/16” for 1000 RPm tractor

Note: if machine sits outside longer than 30 days and is exposed to rain and humid air, the clutches should be

removed from machine and store in dry area. Clutch facing will soak up moisture and cause the metal plates

to rust badly. When this occur, the break-away torque increases greatly and damage to gearbox, driveline, or

tractor PTO can occur.

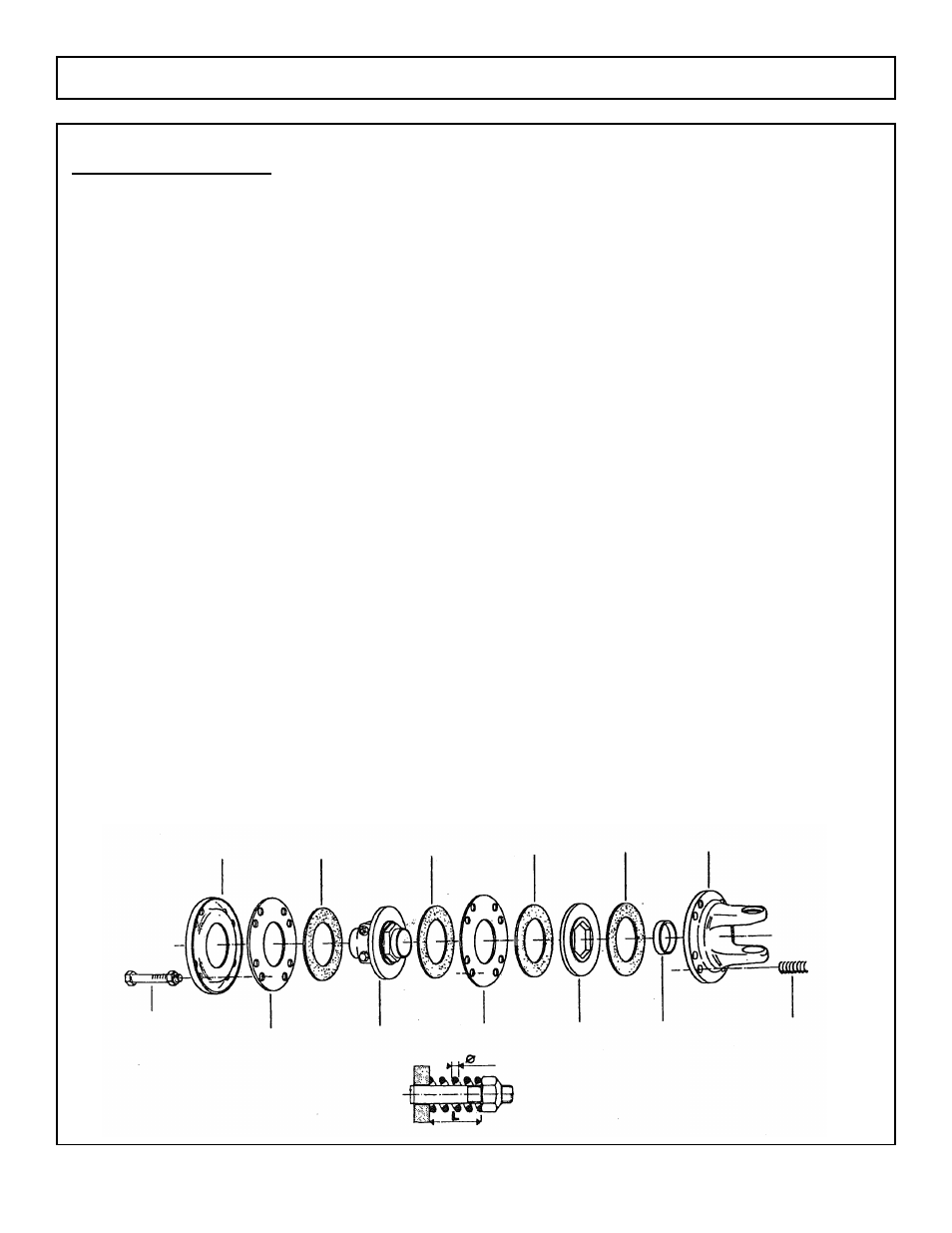

Pressure plate

Friction plate

Friction plate Friction plate Friction plate Flange yoke

Bolt set

inner plate

inner plate

driving plate

Bushing

spring

Flange hub

L= 1 1/8” (28.5 mm) for 540 RPM machine

L= 1 3/16” (30 mm) for 1000 RPM machine