Wheels and tires, Changing a wheel – Mercedes-Benz CLS-Class 2015 User Manual

Page 371

Only position the jack at the appropriate jack-

ing point of the vehicle. The base of the jack

must be positioned vertically, directly under

the jacking point of the vehicle.

!

The jack is designed exclusively for jack-

ing up the vehicle at the jacking points.

Otherwise, your vehicle could be damaged.

Observe the following when raising the vehi-

cle:

R

To raise the vehicle, only use the vehicle-

specific jack that has been tested and

approved by Mercedes-Benz. If used incor-

rectly, the jack could tip over with the vehi-

cle raised.

R

The jack is designed only to raise and hold

the vehicle for a short time while a wheel

is being changed. It is not suited for per-

forming maintenance work under the vehi-

cle.

R

Avoid changing the wheel on uphill and

downhill slopes.

R

Before raising the vehicle, secure it from

rolling away by applying the parking brake

and inserting wheel chocks. Never disen-

gage the parking brake while the vehicle is

raised.

R

The jack must be placed on a firm, flat and

non-slip surface. On a loose surface, a

large, flat, load-bearing underlay must be

used. On a slippery surface, a non-slip

underlay must be used, e.g. rubber mats.

R

Do not use wooden blocks or similar

objects as a jack underlay. Otherwise, the

jack will not be able to achieve its load-

bearing capacity due to the restricted

height.

R

Make sure that the distance between the

underside of the tires and the ground does

not exceed 1.2 in (3 cm).

R

Never place your hands and feet under the

raised vehicle.

R

Do not lie under the vehicle.

R

Do not start the engine when the vehicle is

raised.

R

Do not open or close a door or the trunk lid

when the vehicle is raised.

R

Make sure that no persons are present in

the vehicle when the vehicle is raised.

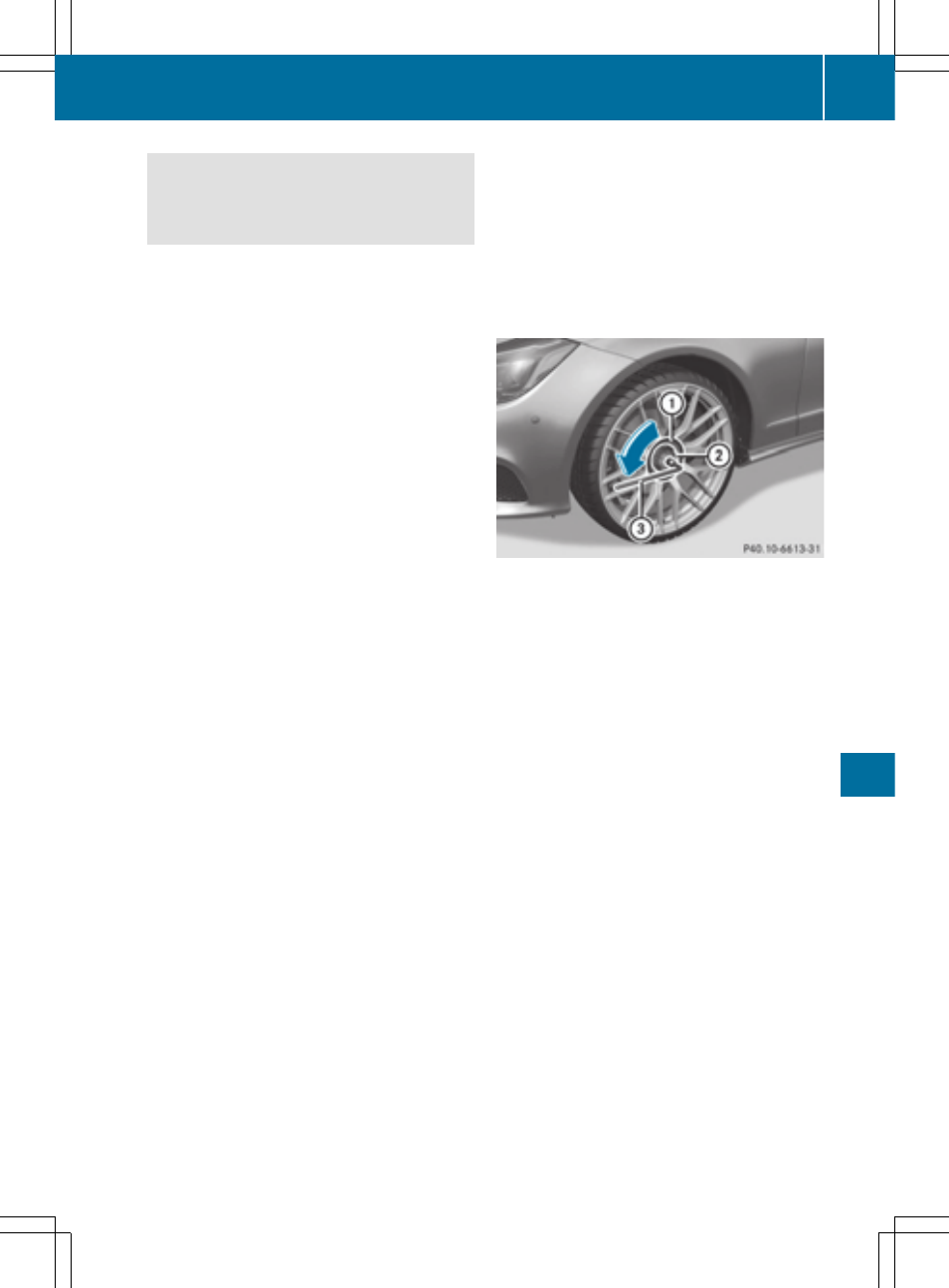

Vehicles with alloy wheels and hub caps:

the wheel bolts are covered by a hub cap.

Before you can unscrew the wheel bolts, you

must remove the hub cap.

X

To remove: remove socket ; and lug

wrench = (

Y

page 326).

X

Position socket ; on hub cap :.

X

Attach lug wrench = to socket ; and turn

hub cap : counter-clockwise.

X

Remove hub cap :.

X

To install: before installing, check hub

cap : and the wheel area for soiling and

clean if necessary.

X

Put hub cap : in position and turn until it is

in the right position.

X

Position socket ; on hub cap :.

X

Attach lug wrench = to socket ; and

tighten hub cap :.

The tightening torque must be

18 lb-ft (25 Nm).

i

Note that the hub cap should be tight-

ened to the specified torque of 18 lb-ft

(25 Nm). Mercedes-Benz recommends

that you have the hub cap installed at a

qualified specialist workshop.

Changing a wheel

369

Wheels

and

tires

Z