Step 2 (continued) – Hybrid Racing HR Autotensioning AC and Power steering removal kit User Manual

Page 3

Step 2 (continued):

One of the unique features about this autoten-

sioner is that it’s designed to use different belt

sizes without compromising performance by main-

taining proper belt tension through an adjustable

spring housing.

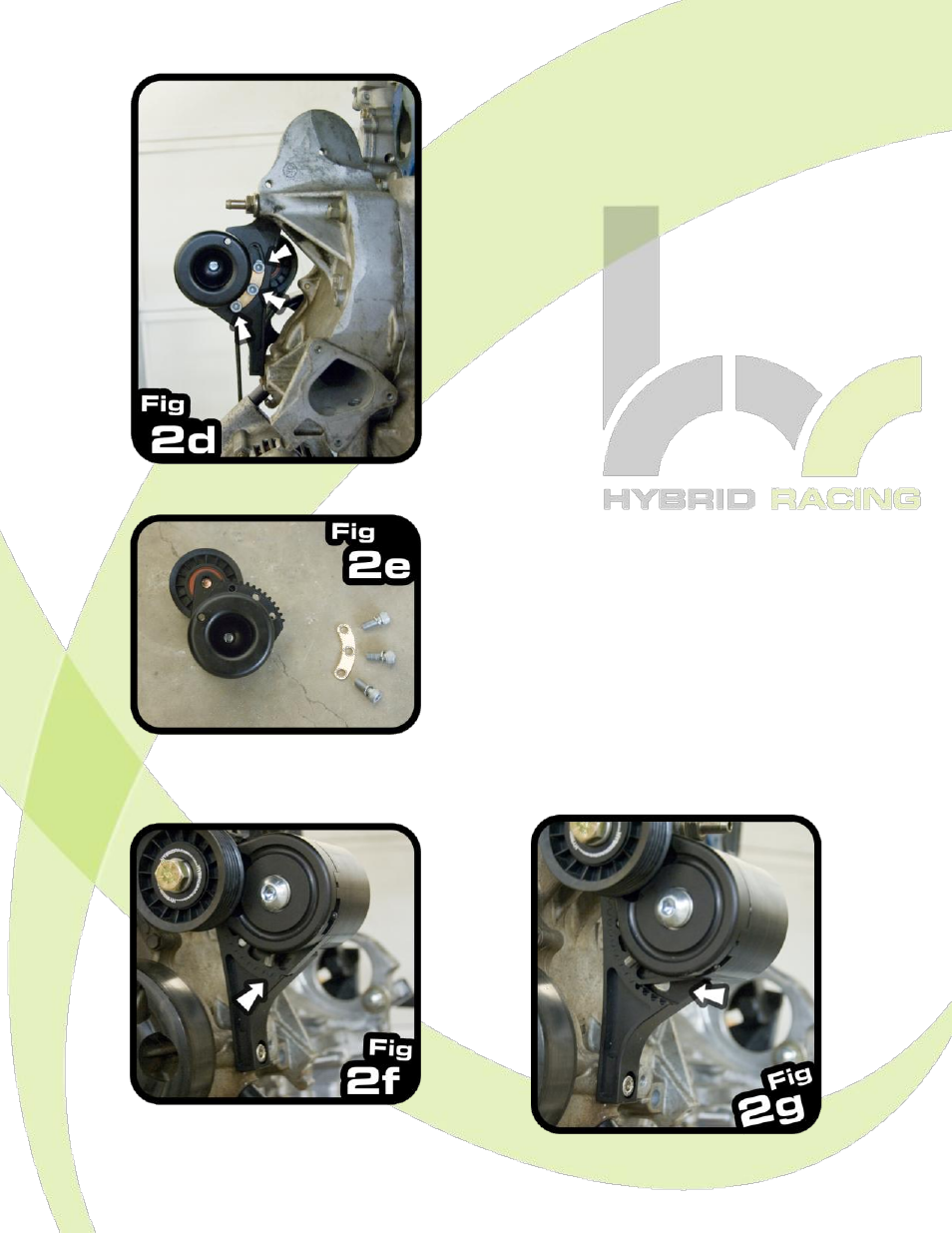

Figure 2d shows the 3 bolts that must be re-

moved to adjust the spring housing. The bolts are

an M8x1.25 thread and can be removed using a

6mm allen driver. Figure 2e shows the parts that

should be loose once the spring housing has been

removed. Shown from left to right is (1) spring

housing, (1) bolt backing plate, and (3) M8 bolts

and M8 lock washers. Torque all three M8 bolts

to 35 lb-ft (dry) or 28 lb-ft (lubricated with oil).

Failure to properly torque bolts can result in pre-

mature fatigue or loosening of the bolts.

The autotensioner is supplied in its lowest position.

Figure 2f shows how no open grooves are visible

at the lower portion of the autotensioner. Figure

2g shows the autotensioner adjusted to its highest

setting, where 4 grooves are showing. In the case

of a k24, typically 2-3 grooves will need to show if

the supplied belt is used. In the case of a k20,

typically 3-4 grooves will need to show if the sup-

plied belt is used. The supplied belt is a 48.5” long

6-rib belt. Note that between the lowest and high-

est settings, there is enough adjustment to com-

pensate for about a 2” variation in belt length. This

allows some flexibility when it comes time to re-

place your belt.