Attaching the propeller and spinner, Propeller drilling – Evolution Engines 62GXI User Manual

Page 8

8

Attaching the Propeller and Spinner

Refer to the Propeller Drilling section for

instructions on how to properly drill a

propeller.

1. Remove the 4 propeller screws from the prop

driver.

2. Insert the 4 screws through the front prop

washer, followed by the propeller, spinner

backplate, rear prop washer and finally

thread them into the prop driver.

3. Begin to tighten all 4 screws until they are all

hand-tight.

4. Tighten all screws with the included 4mm

L-wrench in a clockwise circle until all screws

are tight.

5. Install the spinner cone. Make sure the

spinner cone is not touching the propeller.

Trim the propeller opening if necessary.

6. Tighten the spinner screw to secure the

spinner cone.

Recommended propellers

22 x 10–24 x 10 (a Falcon 23 x 9 has tested

to be the best performer with this engine,

although the performance is very good

throughout the recommended range).

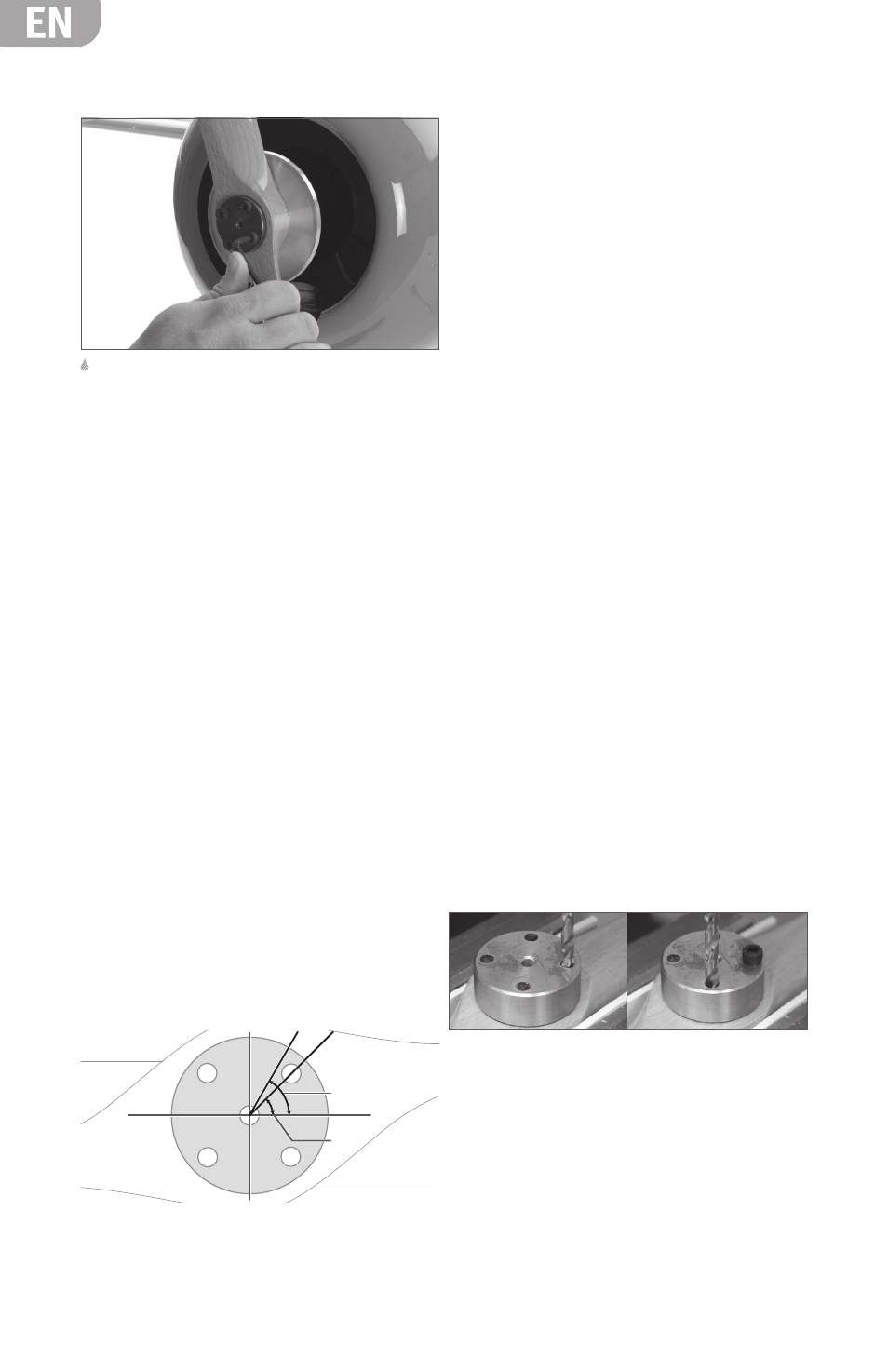

Propeller Drilling

Use a manufacturer’s drill guide to drill four holes in the propeller. The guide ensures that the

propeller bolts align with the driver and do not cross-thread. If you do not have a drill guide, use

one of the propeller washers from the engine; however, this method is not recommended and may

result in poor fitment and damage to the propeller washer. If using a propeller washer, follow the

same instructions as below. Using a drill press is also highly recommended, but not required.

1. If your propeller has a 10mm (0.39 in) center

hole, move to Step 2. If not, use a propeller

reamer to widen the center hole to 10mm.

2. Place the drill guide into the propeller center

hole.

3. Align the bolt pattern where it is convenient

when mounted on the engine. See below

for the best alignment. This will orient

the propeller so that it is in a comfortable

position to hand-start when up against

compression. It is best to check this on your

engine first.

60°

45°

4. While using a secure method to hold the

propeller and drill guide (we recommend

a vise), drill the first hole (order does not

matter). Drill carefully and take your time.

The more precisely you drill the propeller,

the better the fitment of the bolts. If drilling a

carbon fiber propeller, pull the bit out every

few seconds to clear the hole of any material

and allow the bit to cool. Drilling through

carbon fiber is tough on drill bits and takes

longer to complete than wood or plastic.

5. Before drilling any more holes, take a propeller

bolt and place it in the newly created hole. This

will help keep the drill guide aligned and keep

it from rotating when drilling the other holes.

6. Drill the rest of the holes.

7. Remove the drill guide.

8. If desired, take a chamfering tool and

carefully cut a chamfer in each hole on each

side of the propeller.