EFCO Duracast Pressure Plate User Manual

Page 8

EFCO CORPORATION 6/2012 PART NO. YW45

8

Duracast Pressure Plate Installation Instructions

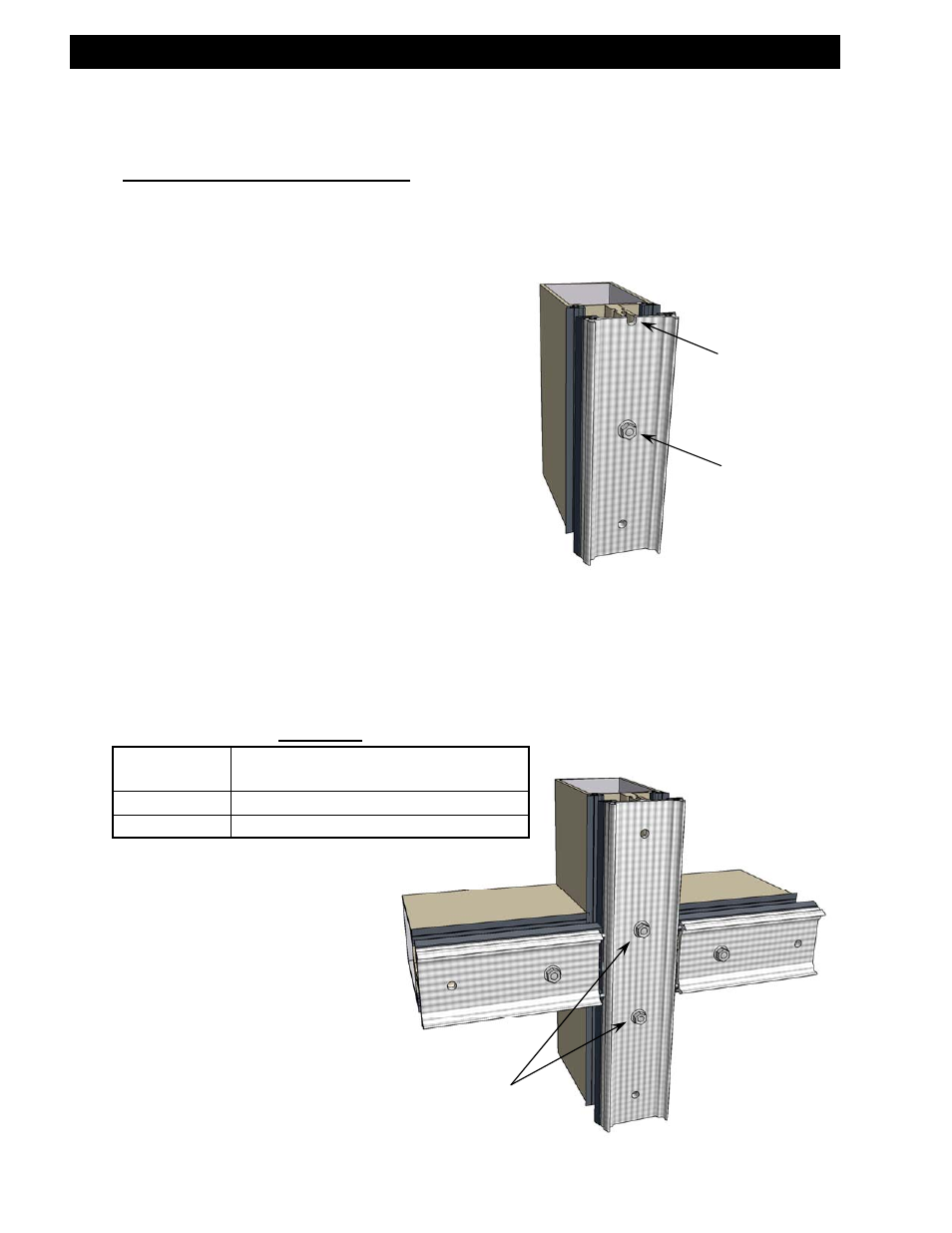

STEP #4 Install Pressure Plate

A. First attach the vertical pressure plates and then the horizontal pressure

plates into position using stainless steel hex washer head screws (refer to

Table #1 for screw size based on Curtain Wall Series). Locate screws in

the first complete pre-punched hole

on each end of the pressure plate no

more than 3.5” from the end. Refer

to the final approved shop drawings

for screw spacing.

B. Torque screws to 80 inch-pounds.

C. In cold Weather, first torque all

pressure plate screws to 40 inch-

pounds. Once all four sides have

been clamped down, torque all

screws to 80 inch-pounds.

D. When possible, work from the center

outward on horizontals and from the

sill upward on verticals.

E. Glazier should always place screws in

pre-punched holes immediately above and below each horizontal. This will

provide maximum control of pressure on mullion plugs that provide a criti-

cal sealing function.

F. The pressure plate should extend 3” past any splice (see Section IV:

Vertical Splice Joints).

Section III: Pressure Plate Installation

Pressure Plate End

Incomplete Hole

Hex washer head

screw in first

complete hole

(see Table #1).

Place screws in holes

immediately above and

below all horizontals

Table #1

Curtain Wall

Series

Screw Size & Type

5600

#13 x 5/8" S.S. Hex Washer Head Screw

5900

¼" x 1" S.S. Hex Washer Head Screw