Setup, Tester setup – CDI Torque TORQUE AND ANGLE Electronic Torque Wrench User Manual

Page 7

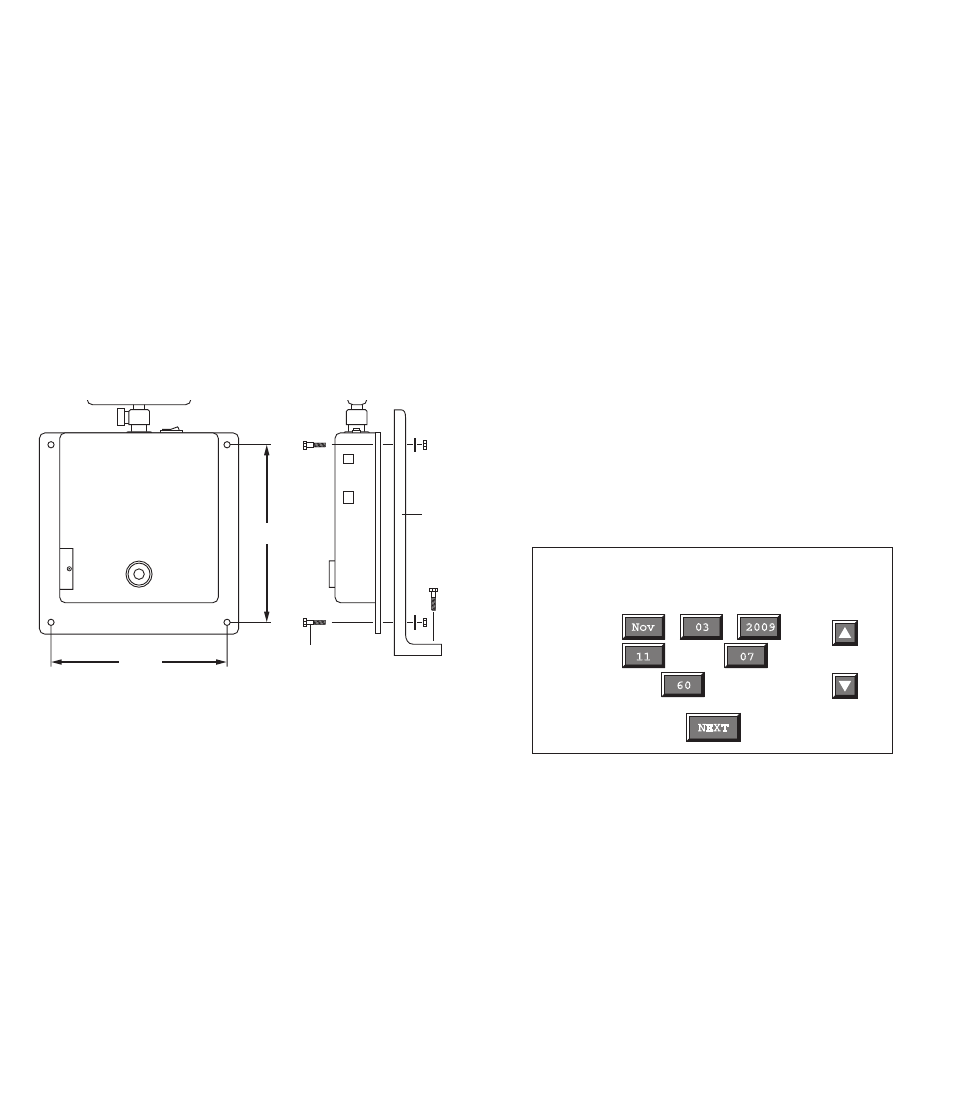

sETUP

MOUNTING

Mount the DTT to a sturdy support before use. Torque

testing procedures may involve hundreds of pounds of

load. Be sure to consider counterweight of the mount

to accommodate torque testing operations and testing

fixtures. Allow enough room around and below the

mount for the wrenches or testing fixtures being used.

Vertical mounting on a wall or heavy pillar is preferred

for most wrench and tool testing as shown in the

illustration below. Use four 1/4” diameter bolts

(torqued to 10 ft.lb.) to insure a secure mount. The DTT

can also be mounted vertically to a horizontal surface

using a right angle bracket.

TEsTER sETUP

1.

Turn the power switch ON.

2.

In the MAIN MENU screen, select DTT SETTINGS.

3.

In the SYSTEM CONFIGURATION screen, the display

reads:

DATE:

MONTH / DAY / YEAR

TIME:

HOUR/MINS

BRIGHTNESS:

30-100

4.

To increment or decrement the DATE/TIME/

BRIGHTNESS elements, select the element and

repeatedly press the UP or DOWN arrows.

NOTE: Press and hold the UP or DOWN arrows to

change the display quickly. The scrolling DATE/

TIME elements roll over at both ends for quick

and convenient adjustment of settings.

5.

Press NEXT to update DATE/TIME/BRIGHTNESS and

return to the MAIN MENU.

SYSTEM CONFIGURATION

SW VERSION: 1.X.X

CHECKSUM: A1XX

DATE:

03

2009

Nov

11

07

60

NEXT

TIME:

HR

MIN

BRIGHTNESS:

DIGITAL TORQUE TESTER

TEST SETUP

TGT TORQUE

:

250 FT-LB

SERIAL NUM

:

110900MAW

OPERATOR ID

ENTER TARGET TORQUE VALUE :

:

TECH512

NEXT

MAIN

1

2

3

4

5

6

7

8

9

0

BS

CLEAR

NEXT

UNITS

250

FT-LB

ENTER WRENCH MAX RANGE :

MAIN

1

2

3

4

5

6

7

8

9

0

BS

CLEAR

NEXT

UNITS

250

FT-LB

ENTER WRENCH S/N:

1

2

3

4

5

6

7

8

9

A-Z

0

BS

CLEAR

NEXT

110900

ENTER WRENCH S/N:

CLEAR

NEXT

110900MAW

ENTER OPERATOR ID:

1

2

3

4

5

6

7

8

9

A-Z

0

BS

CLEAR

NEXT

TECH512

NEXT

CHANGE

CHANGE

CHANGE

DIGITAL TORQUE TESTER

TEST SETUP

WRENCH SIZE :

250 FT-LB

SERIAL NUM

:

110900MAW

OPERATOR ID :

TECH512

MAIN

TEST

CHANGE

CHANGE

CHANGE

Q

A

0-9

Z

X

C

V

B

N

M

BS

S

D

F

G

H

J

K

L

W

E

R

T

Y

U

I

O

P

ENTER OPERATOR ID:

CLEAR

NEXT

TECH

Q

A

0-9

Z

X

C

V

B

N

M

BS

S

D

F

G

H

J

K

L

W

E

R

T

Y

U

I

O

P

TGT TORQUE: 250

TEST 1 OF 3

FIRST PEAK

FT-LB

0.00

DATA: 1

MAIN MENU

STORE

TGT TORQUE: 150

TEST 1 OF 3

FIRST PEAK

FT-LB

0.00

DATA: 3

MAIN MENU

STORE

TGT TORQUE: 250

FIRST PEAK

FT-LB

0.00

DATA: 25

MAIN MENU

SETUP

STORE

NEXT

PLEASE SET WRENCH TO 50 FT-LB

NEXT

PLEASE SET WRENCH TO 150 FT-LB

NEXT

PLEASE SET WRENCH TO 250 FT-LB

8.87”

A

B

8.87”

A

A

B

C

D

G

H

I

F

E

B

C

D

TGT TORQUE: 250

FIRST PEAK

FT-LB

0.00

DATA: 25

MAIN MENU

SETUP

STORE

FT-LB

0.00

SYSTEM CONFIGURATION

SW VERSION: 1.X.X

CHECKSUM: A1XX

DATE:

03

2009

Nov

11

07

60

NEXT

TIME:

HR

MIN

BRIGHTNESS:

DIGITAL TORQUE TESTER

TEST SETUP

TGT TORQUE

:

250 FT-LB

SERIAL NUM

:

110900MAW

OPERATOR ID

ENTER TARGET TORQUE VALUE :

:

TECH512

NEXT

MAIN

1

2

3

4

5

6

7

8

9

0

BS

CLEAR

NEXT

UNITS

250

FT-LB

ENTER WRENCH MAX RANGE :

MAIN

1

2

3

4

5

6

7

8

9

0

BS

CLEAR

NEXT

UNITS

250

FT-LB

ENTER WRENCH S/N:

1

2

3

4

5

6

7

8

9

A-Z

0

BS

CLEAR

NEXT

110900

ENTER WRENCH S/N:

CLEAR

NEXT

110900MAW

ENTER OPERATOR ID:

1

2

3

4

5

6

7

8

9

A-Z

0

BS

CLEAR

NEXT

TECH512

NEXT

CHANGE

CHANGE

CHANGE

DIGITAL TORQUE TESTER

TEST SETUP

WRENCH SIZE :

250 FT-LB

SERIAL NUM

:

110900MAW

OPERATOR ID :

TECH512

MAIN

TEST

CHANGE

CHANGE

CHANGE

Q

A

0-9

Z

X

C

V

B

N

M

BS

S

D

F

G

H

J

K

L

W

E

R

T

Y

U

I

O

P

ENTER OPERATOR ID:

CLEAR

NEXT

TECH

Q

A

0-9

Z

X

C

V

B

N

M

BS

S

D

F

G

H

J

K

L

W

E

R

T

Y

U

I

O

P

TGT TORQUE: 250

TEST 1 OF 3

FIRST PEAK

FT-LB

0.00

DATA: 1

MAIN MENU

STORE

TGT TORQUE: 150

TEST 1 OF 3

FIRST PEAK

FT-LB

0.00

DATA: 3

MAIN MENU

STORE

TGT TORQUE: 250

FIRST PEAK

FT-LB

0.00

DATA: 25

MAIN MENU

SETUP

STORE

NEXT

PLEASE SET WRENCH TO 50 FT-LB

NEXT

PLEASE SET WRENCH TO 150 FT-LB

NEXT

PLEASE SET WRENCH TO 250 FT-LB

8.87”

A

B

8.87”

A

A

B

C

D

G

H

I

F

E

B

C

D

TGT TORQUE: 250

FIRST PEAK

FT-LB

0.00

DATA: 25

MAIN MENU

SETUP

STORE

FT-LB

0.00

Figure 4: System Configuration screen

Figure 3: Mounting, Dimensions and Right Angle Bracket

A - Mounting Screw (4)

B- Right Angle Bracket