Dtt system components, Introduction – CDI Torque TORQUE AND ANGLE Electronic Torque Wrench User Manual

Page 4

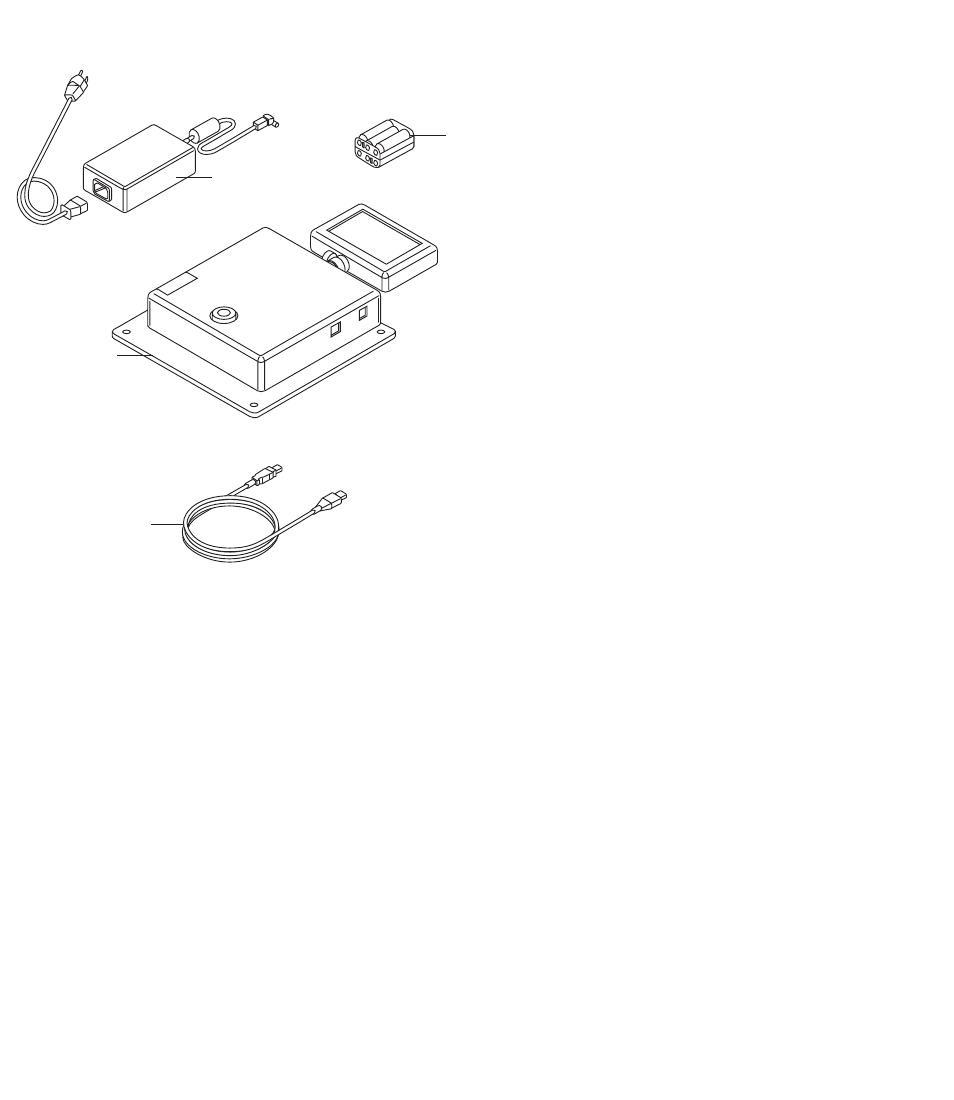

DTT sYsTEM cOMPONENTs

Use the portable DTT to test “click” type torque wrenches

(adjustable and preset), torque screwdrivers, dial

indicating and electronic wrenches.

The tester features a swivel-neck LCD display with

selectable English or Metric units of measure. 11 models

are available, ranging from 10-100 in.oz. to 60-600 ft.lb.

The DTT displays torque values using a built-in

straingaged transducer with an accuracy of ±0.5% of

indicated test value from 10% to 100% of rated capacity,

in clockwise (CW) and counter-clockwise (CCW) directions.

TORqUE VALUES

Capture and display torque values in one of four

selectable modes:

• CLICK ADJUST (First Peak)

— Responds to the drop-off in torque caused by the

“click” of an adjustable wrench. FIRST PEAK torque

is measured, captured and displayed (CW or CCW)

just prior to the drop-off, even if click torque is

subsequently exceeded.

• CLICK PRESET (First Peak)

— Responds to the drop-off in torque caused by the

“click” of a preset wrench. FIRST PEAK torque is

measured, captured and displayed (CW or CCW)

just prior to the drop-off, even if click torque is

subsequently exceeded.

• DIAL / ELECT (Peak Hold)

— Captures and displays the highest torque applied

(CW or CCW) until reset. Use to check dial indicating

and electronic torque wrenches.

• SCREWDRIVER (Peak Hold)

— Captures and displays the highest torque applied

(CW or CCW) until reset. Use to check torque limiting

screwdrivers.

This manual contains general information. Operating

features and specifications may change without notice.

CDI Torque makes no claims regarding the suitability

of the information in this manual for diverse user

applications.

POWER SOURCE

The power source for the DTT is the supplied AC Adapter.

The tester can also be operated with the use of the 6 AA

Battery Pack that accompanies the tester.

INTRODUcTION

SYSTEM CONFIGURATION

SW VERSION: 1.X.X

CHECKSUM: A1XX

DATE:

03

2009

Nov

11

07

60

NEXT

TIME:

HR

MIN

BRIGHTNESS:

DIGITAL TORQUE TESTER

TEST SETUP

TGT TORQUE

:

250 FT-LB

SERIAL NUM

:

110900MAW

OPERATOR ID

ENTER TARGET TORQUE VALUE :

:

TECH512

NEXT

MAIN

1

2

3

4

5

6

7

8

9

0

BS

CLEAR

NEXT

UNITS

250

FT-LB

ENTER WRENCH MAX RANGE :

MAIN

1

2

3

4

5

6

7

8

9

0

BS

CLEAR

NEXT

UNITS

250

FT-LB

ENTER WRENCH S/N:

1

2

3

4

5

6

7

8

9

A-Z

0

BS

CLEAR

NEXT

110900

ENTER WRENCH S/N:

CLEAR

NEXT

110900MAW

ENTER OPERATOR ID:

1

2

3

4

5

6

7

8

9

A-Z

0

BS

CLEAR

NEXT

TECH512

NEXT

CHANGE

CHANGE

CHANGE

DIGITAL TORQUE TESTER

TEST SETUP

WRENCH SIZE :

250 FT-LB

SERIAL NUM

:

110900MAW

OPERATOR ID :

TECH512

MAIN

TEST

CHANGE

CHANGE

CHANGE

Q

A

0-9

Z

X

C

V

B

N

M

BS

S

D

F

G

H

J

K

L

W

E

R

T

Y

U

I

O

P

ENTER OPERATOR ID:

CLEAR

NEXT

TECH

Q

A

0-9

Z

X

C

V

B

N

M

BS

S

D

F

G

H

J

K

L

W

E

R

T

Y

U

I

O

P

TGT TORQUE: 250

TEST 1 OF 3

FIRST PEAK

FT-LB

0.00

DATA: 1

MAIN MENU

STORE

TGT TORQUE: 150

TEST 1 OF 3

FIRST PEAK

FT-LB

0.00

DATA: 3

MAIN MENU

STORE

TGT TORQUE: 250

FIRST PEAK

FT-LB

0.00

DATA: 25

MAIN MENU

SETUP

STORE

NEXT

PLEASE SET WRENCH TO 50 FT-LB

NEXT

PLEASE SET WRENCH TO 150 FT-LB

NEXT

PLEASE SET WRENCH TO 250 FT-LB

8.87”

A

B

8.87”

A

A

B

C

D

G

H

I

F

E

B

C

D

TGT TORQUE: 250

FIRST PEAK

FT-LB

0.00

DATA: 25

MAIN MENU

SETUP

STORE

FT-LB

0.00

Figure 1: Digital Torque Tester (DTT) System Components

A - Digital Torque Tester (DTT)

B - AC Adapter

AC/DC transformer, Voltage Output: 9VDC,

Current 1.66A

C - Battery Pack

Battery holder with 6 AA Battery Cells

D - USB Cable