Attwood Sahara Series Automatic Bilge Pumps User Manual

Sahara series automatic bilge pumps

4505 / 4507 / 4511 Installation Instructions

SA

VE THESE INSTRUCTIONS

Form Number 69370 Rev

. D

08-09

Sahara Series Automatic

Bilge Pumps

CAUTION:

Read all instructions carefully before installing and using this product.

This pump is sealed and, therefore, submersible. However

, the electrical wire connections must not

be submerged. For extra protection, coat the butt joints and adjacent wire ends liberally with liquid

electrical tape such as MDR

®

or Starbrite

®

.

Specifi

cations

ABYC Specifi

cations

ISO Specifi

cations

13.6-volts DC

12.0-volts DC

(GPH=Gallons Per Hour)

(LPH=Liters Per Hour)

0 ft.

3.3 ft.

6.7 ft.

10kPa

20kPa

Head

Head

Head

Head

Head

Max

Head

Part

Amp

GPH/

GPH/ GPH/ LPH/

LPH/

Num.

Model

Fuse

amps

amps amps amps

amps

kPa@12v)

4505

S500

2.0

500/1.5

350/1.4 200/1.4 1136/1.2

598/1.2

9'/24

4507

S750

5.0

750/3.0

625/2.8 450/2.8 1817/2.5

1306/2.5

16'/36

4511

S1100

6.0

1100/4.0

970/3.8 750/3.8 3104/3.3

2328/3.3

11'7"/28

W

A

RNING:

T

o

prevent injur

y,

always disconnect the power sour

ce when installing or ser

vicing

any electrical product.

DO NOT use pump to remove gasoline, oil or other fl

ammable liquids.

Always use the fuse amperage rating specifi

ed for your pump model. Failure to do so could result in

serious personal injur

y or fi

re hazards.

Attwood bilge pumps are designed to exhaust ST

ANDING W

A

TER ONL

Y.

They are not intended to

prevent rapid accumulation of on-board water due to rough weather

, hull damage, and/or other

unsafe navigational conditions.

REQUIRED MA

TERIALS

•

Hose and thru-hull fi

ttings, available separately from Attwood:

Sahara Model 4505 and 4507–

3/4" I.D. hose: Attwood No. 4199 (includes 2 clamps)

3/4" I.D. thru-hull: No. 3873 (straight), No. 66541 or 66547 (stainless steel straight), No. 3877

(90°), or No. 3878 (double-end)

Sahara Model 4511–

1-1/8" I.D. hose: No. 11551 (clamps not included)

1-1/8" I.D. thru-hull: No. 3874 (white), No. 3874A (black) or

No. 66543, 66549 (stainless steel), or No. 3879 (90°)

•

Two (2) hose clamps suitable for (3/4" or 1-1/8") hose.

•

AUTO/OFF/MANUAL dash-mounted control switch (Attwood No. 7615A).

•

In-line fuse connector (Attwood No. 14341) and appropriate size fuse.

•

Three (3) stainless steel #6 x 1/2" self-tapping screws, round or pan head. Use a #32 drill bit for

pilot holes.

•

Four (4) wire butt-connectors for 16-gauge wire.

•

Two (2) insulated spade terminal connectors for 16-gauge wire.

•

Suitable means to make electrical connections waterproof.

• Cordless

drill.

• Screwdriver

.

OPTIONAL MA

TERIALS

•

1/2"-thick marine plywood block (slightly larger than pump base).

•

W

aterproof adhesive (epoxy

, silicone adhesive, or fi

berglass resin) to mount block.

•

16-gauge wire (brown and black).

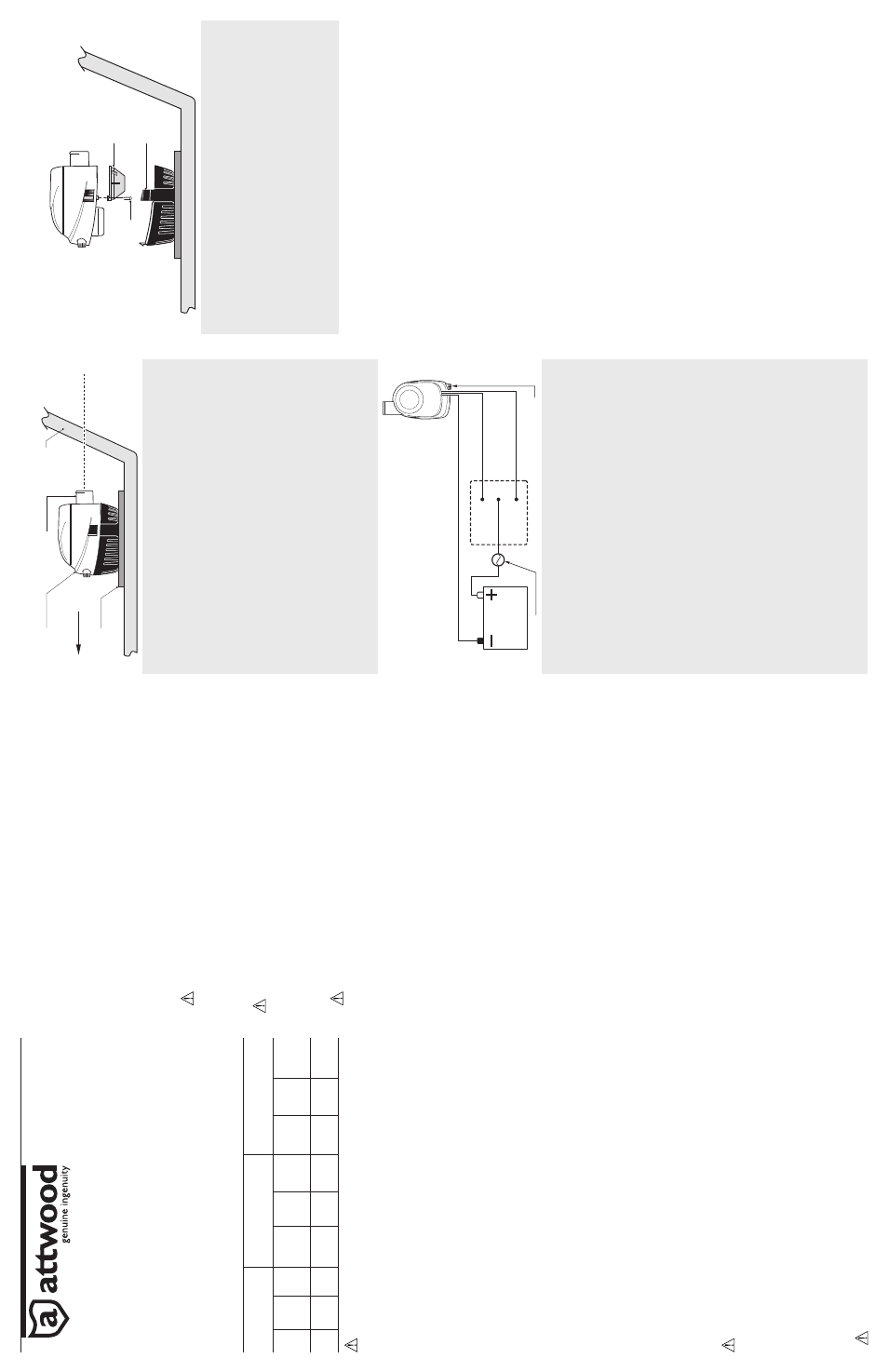

PUMP MOUNTING INSTRUCTIONS

W

A

RNING:

Remove the pump mounting base (See Figure 3). Failure to do this prevents the

pump from starting when water is present.

1.

Make sure the hull thickness is at least 1/2" thick. If not, place a block of 1/2" marine plywood

(slightly larger than pump base) in the lowest part of the bilge. Be sure that the pump cover can

be removed for cleaning in this position. Glue the plywood to the hull with a waterproof adhesive

(epoxy

, silicone adhesive, or fi

berglass resin). See Figure 1.

2.

Position the pump in the lowest part of the bilge on a fl

at, level sur

face (on the plywood block if it

has been installed) with the outlet pointing toward the transom.

3.

Be sure outlet nozzle is level. If pointed upward or downward,

an airlock may form in the pump.

(See Figure 1.)

4.

The fl

oat end of the pump must be level with or above the pump end

(See Figure 1). This prevents

the pump from running out of water while the fl

oat is still high enough to activate the pump.

5.

Mark location of the three (3) mounting holes with a pencil or scribe.

W

A

RNING:

When drilling holes do not drill through the hull!

6.

Carefully drill two 1/8" diameter pilot holes in marked area and drive a screw in each hole.

7.

Slide hose clamps (one to clamp hose to the pump, the other for the thru-hull connector) over end

of the hose. For

ce hose over the discharge nozzle of the pump. Install clamp.

8.

Route hose on an upward incline to the thru-hull connector

. A

void dips in hose that can trap water

and airlock the pump. A

void putting excess tension on hose, which can damage the pump outlet.

9.

For

ce the hose over the thru-hull barbs and clamp into place.

THRU-HULL CONNECTOR INSTRUCTIONS

If no thru-hull connector exists, choose a location for the fi

tting.

1.

Position thru-hull fi

ttings at least 12" above the water line to prevent water from coming back into

the hull. On sailboats, mount the thru-hull high enough on the center of the transom to be above

the water line at all times.

2.

Place fi

tting, if possible, on the same side as the steering wheel so the driver can see discharge of

water when the pump is working properly

.

3.

Drill hole to match outside diameter of the thru-hull connector thread.

4.

Place a small bead of suitable marine sealant around inside of the thru-hull connector fl

ange.

W

A

RNING:

Do not allow sealants containing acetic acid (smells like vinegar) such as

silicone rubber sealant to contact the plastic pump housing or thru-hull connector

. Such sealants

can attack the plastic, causing the pump housing to crack, resulting in pump failure.

5.

Insert thru-hull connector through the hole and tighten to hold the thru-hull connector fi

rmly in

place.

CAUTION: Do not overtighten the nut.

WIRING INSTRUCTIONS

W

A

RNING:

Be certain that power sour

ce is 12-volt D.C. Higher voltage will damage the pump.

1.

Using the full length of wire provided (and additional wire if necessar

y), connect wires to the pump

as shown in the diagram. (See Figure 2.)

2.

Route wires out of the way and secure them to the bulkhead to avoid pulling.

3.

Using butt connectors sized for 16-gauge wire, splice fuse holder into positive lead (brown) between

the batter

y and switch. Position fuse holder in a location that is easily accessible for changing fuses.

IMPOR

TANT

:

Use fuses of the proper amperage (See Specifi

cation Chart at top of sheet).

W

A

RNING:

F

AILURE TO PROPERL

Y FUSE AND MAKE THE APPROPRIA

TE W

A

TERPROOF

CONNECTIONS WILL VOID THE PRODUCT W

ARRANTY

.

4

. Install a Three-W

ay Switch (Attwood No. 7615A) that allows for automatic or manual switching modes.

5.

Turn the pump on and twist the T

est Knob clockwise to check operation. Feed water into the pump.

If output appears to be too low

, check the wire connections. Reversed connections result in opposite

impeller rotation that drastically reduces capacity and can cause premature pump failure.

CARE AND MAINTENANCE

Occasionally check your pump to be certain debris is not jamming the impeller and/or fl

oat within

the housing. Use the test knob by rotating in a clockwise direction. Careful attention will guarantee

outstanding pump per

formance.

To

clean the water chamber

, remove pump housing from the mounting base by pressing in tabs on

sides. Lift the pump housing away

. (See Figure 3.)

To

clean the impeller

, remove the impeller guard screw and lift the impeller guard.

Remove all debris that has accumulated in pump chamber and around the impeller

. Ensure that all

debris is removed from strainer slots around the pump base.

Inspect the impeller to ensure that it is fi

rmly attached to shaft and is not cracked or broken.

Replace impeller guard, screw

, and pump housing on base. Be certain that all tabs are fully engaged.

Periodically check the electrical connections to ensure they are water

-resistant and mounted high and dr

y.

Do not use household cleaners on the pump because many of them may damage the pump materials.

A

TTWOOD BILGE PUMPS LIMITED W

ARRANTY

This Attwood Bilge Pump carries a three (3) year warranty

. See product catalog or www

.attwoodmarine.com

for details.

©2008 Attwood Corporation

1016 N. Monroe Street, Lowell, MI 49331-0260 www

.attwoodmarine.com

Figure 1 / Figura 1

Abbildung 1 / Figur 1

D

A

F

BC

E

Figure 2

A.

12 V

olt Batter

y

B.

Suitable Fuse (see chart)

C.

Manual

D.

Off

E.

Automatic

F.

3-W

ay Switch #7615A

G.

Black

H.

Brown/White or T

an

I.

Brown

J.

Te

st Knob

Figure 2

A.

Batterie de 12 volts

B.

Fusible convenable (voir le tableau des spécifi

cations)

C.

Manuel

D.

Arrêt

E.

Automatique

F.

Interrupteur automatique à 3 directions - N°7615A

G.

Noir

H.

Brun/blanc ou beige

I.

Brun

J.

Poignée d’essai

Figura 2

A.

Batería de 12 voltios

B.

Fusible adecuado (ver T

abla)

C.

Manual

D.

Apagado

E.

Automático

F.

Interruptor de tres vías #7615A

G.

Negro

H.

Marrón/blanco o café

I.

Marrón

J.

Perilla de prueba

Abbildung 2

A.

12 V

olt Akkumulator

B.

Passende Sicherung (siehe T

abelle)

C.

V

o

n

Hand

D.

Aus

E.

Automatisch

F.

3-W

eg-Schalter T

eilenummer 7615A

G.

Schwar

z

H.

Braun / W

eiß oder Hellbraun

I.

Braun

J.

Te

stknopf

Figur 2

A.

12-voltsbatteri

B.

passande säkring (se diagram)

C.

manuellt

D.

från

E.

automatiskt

F.

3-vägsströmbr

ytare nr 7615A

G.

svart

H.

brun/vit eller beige

I.

brun

J.

testknapp

Figure 1

A.

Float End Of Pump

B.

Pump Outlet Pointing T

o

T

ransom

C.

Transom

D.

Toward Bow

E.

Level Parallel T

o

Bottom Of Boat

F.

1/2" Thick Mounting Block

Figure 1

A.

Extrémité de la pompe où se trouve le

fl otteur pointant

B.

Orifi

ce de refoulement de la pompe pointant

vers le caisson

C.

Caisson

D.

V

ers

l’étrave

E.

Bloc de fi

xation de 1/2 po d’épaisseur

F.

À niveau et parallèle au fond de l’embar

cation

Figura 1

A.

Extremo fl

otante de la bomba

B.

Salida de la bomba en dirección hacia

la bovedilla

C.

Bovedilla

D.

Hacia la proa

E.

Nivel paralela a la parte inferior de

la embar

cación

F.

Tabla de montaje de 1.3 cm de espesor

Abbildung 1

A.

Schwimmerende der Pumpe

B.

Pumpenauslass zeigt zum Heckspiegel

C.

Heckspiegel

D.

Zum

Bug

E.

Niveau parallel zum Kiel des Boots

F.

Montageplatte 1/2 Zoll

Figur 1

A.

pumpens fl

ottörände

B.

pumputloppet riktat mot akterspegeln

C.

akterspegel

D.

mot

fören

E.

vågrätt parallellt med botten på båten

F.

1/2 tum tjock monteringskloss

G

A

I

D

C

E

F

B

H

J

Figure 2 / Figura 2

Abbildung 2 / Figur 2

Figure 3 / Figura 3

Abbildung 3 / Figur 3

Figure 1

A.

Remove

(1)Screw

B.

Impeller Guard

C.

Depress (2)T

abs

Figure 1

A.

Retirez 1 vis

B.

Garde-palettes

C.

Appuyez sur les (2) languettes

Figura 1

A.

Extraiga (1) tornillo

B.

Protección del impulsor

C.

Pulse las (2) lengüetas

Abbildung 1

A.

Eine Schraube entfernen

B.

Rotorsicherheitsabdeckung

C.

Zwei Laschen hinein drücken

Figur 1

A.

avlägsna (1) skruv

B.

impellerskydd

C.

tr

yck ned (2) fl

ikar

C

B

A