General operation, On/off knob with variable speed, Operation – Craftsman 315.216360 User Manual

Page 16

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

OPERATION

This scroll saw is designed to cut wood, wood compo

sition products, plastic, and nonferrous metals (alumi

num, brass, copper},

GENERAL OPERATION

Please read and understand the following items

concerning your scroll saw before attempting to use

the saw.

■

There is a learning curve for each person who

wants to use this saw. During that period of time

it is expected that some blades will break until

you learn how to use and adjust the saw.

■

Allow the saw to cut material by guiding the

workpiece into the blade as it moves. Do not

force the work.

■

The blade teeth cut material only on the down

stroke.

■

You must guide the workpiece into the blade

slowly because the teeth of the blade are very

small and can only remove material on the down

stroke.

■

Scroll saw blades wear out and must be replaced

frequently for best cutting results. Scroll saw

blades generally stay sharp for 1/2 hour to 2

hours of cutting, depending on type of material

and speed of operation,

■

To get accurate cuts, be prepared to compen

sate for the blade's tendency to follow the wood

grain as you are cutting wood.

■

In cutting wood, best results are achieved when

cutting wood less than one inch thick.

■

When cutting wood thicker than one inch, the

user must guide the workpiece very slowly into

the blade and take extra care not to bend or twist

the blade while cutting.

■

When choosing a blade to use with your scroll

saw, consider the following carefully:

• Very fine, narrow blades should be used to

scroll cut in thin material 1/4 in. thick or less.

• Most blade packages state the size or thick

ness and type of material which that blade is

intended to cut. Package should also state the

radius. Of size of curve, which can be cut with

that blade.

• Wider blades cannot cut curves as tight or

small as thinner blades.

■

Blades wear faster:

• When cutting plywood and other laminates.

• When cutting material thicker than 3/4 in.

• When cutting hardwood.

• When side pressure is applied to the blade.

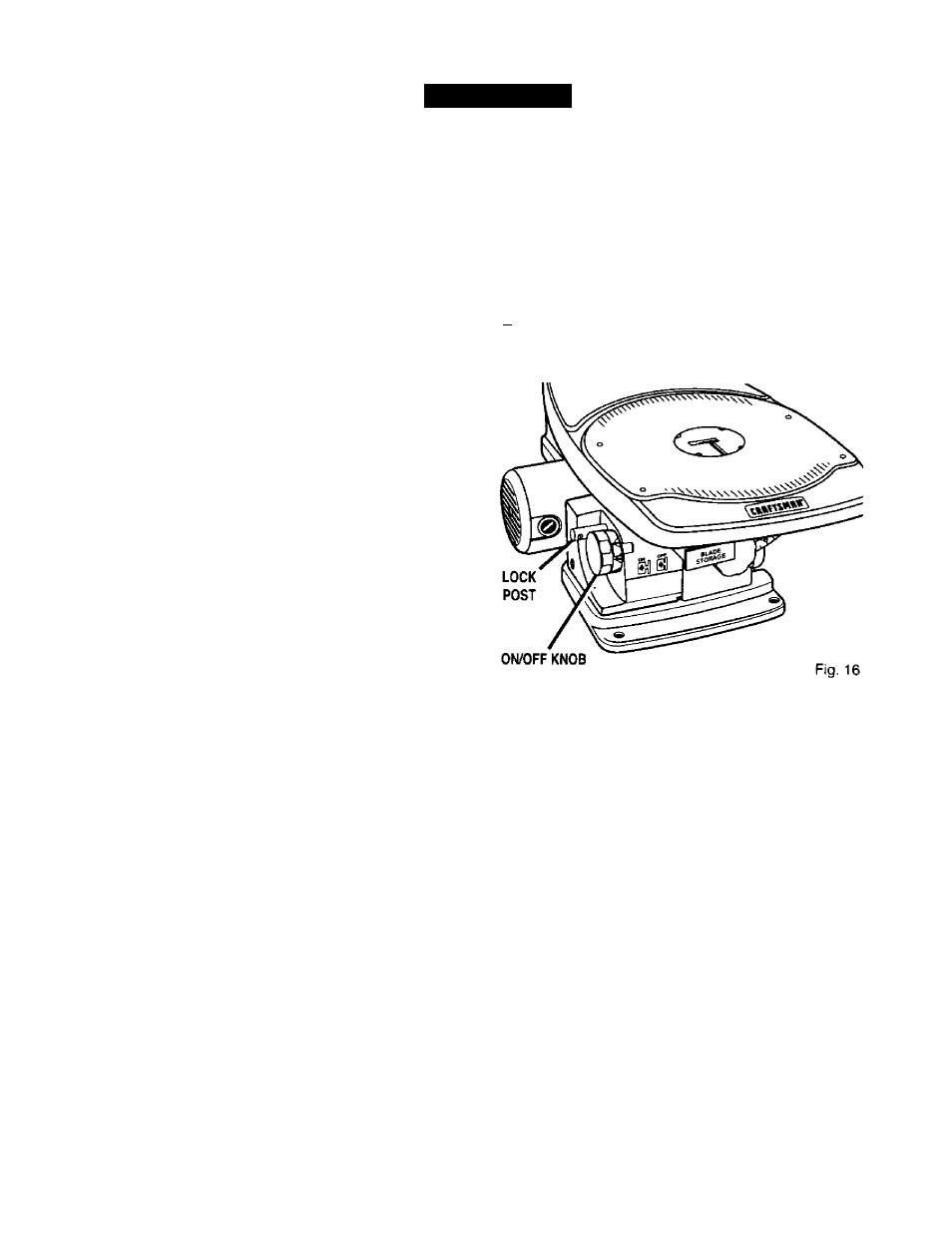

ON/OFF KNOB WITH VARIABLE SPEED

See Figure 16.

Your scroll saw has an easy access On/Off knob with

variable speed.

■ Pull the knob out to turn ON the saw, and push

the knob in to turn OFF the saw.

Note: After saw is turned on, a hesitation before blade

movement is normal.

^ WARNING: Never leave the saw unattended

until the blade has come to a complete stop to

prevent serious personal injury.

■ By turning the knob, the variable speed control

may be adjusted from the high speed of approxi

mately 1600 SPM (Strokes Per Minute) to the

low speed of approximately 500 SPM. Suggested

speeds are identified under Choice of Blade and

Speed, page 18. Turn the On/Off knob to the

right or clockwise to increase strokes per minute

and to the left or counterclockwise to reduce the

strokes per minute.

This motor has an electronic control that regulates the

speed and provides overload protection to the motor.

If the motor fails to start after about 2 seconds, push

the knob OFF and disconnect the saw from the power

source. Refer to the troubleshooting chart.

Note: If the internal overload protector has been

tripped, pushing the On/Off knob OFF will reset it.

16