Lock post, General operation, Use only recommended accessories – Craftsman 315.214500 User Manual

Page 19: Basic operation

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

BASIC OPERATION

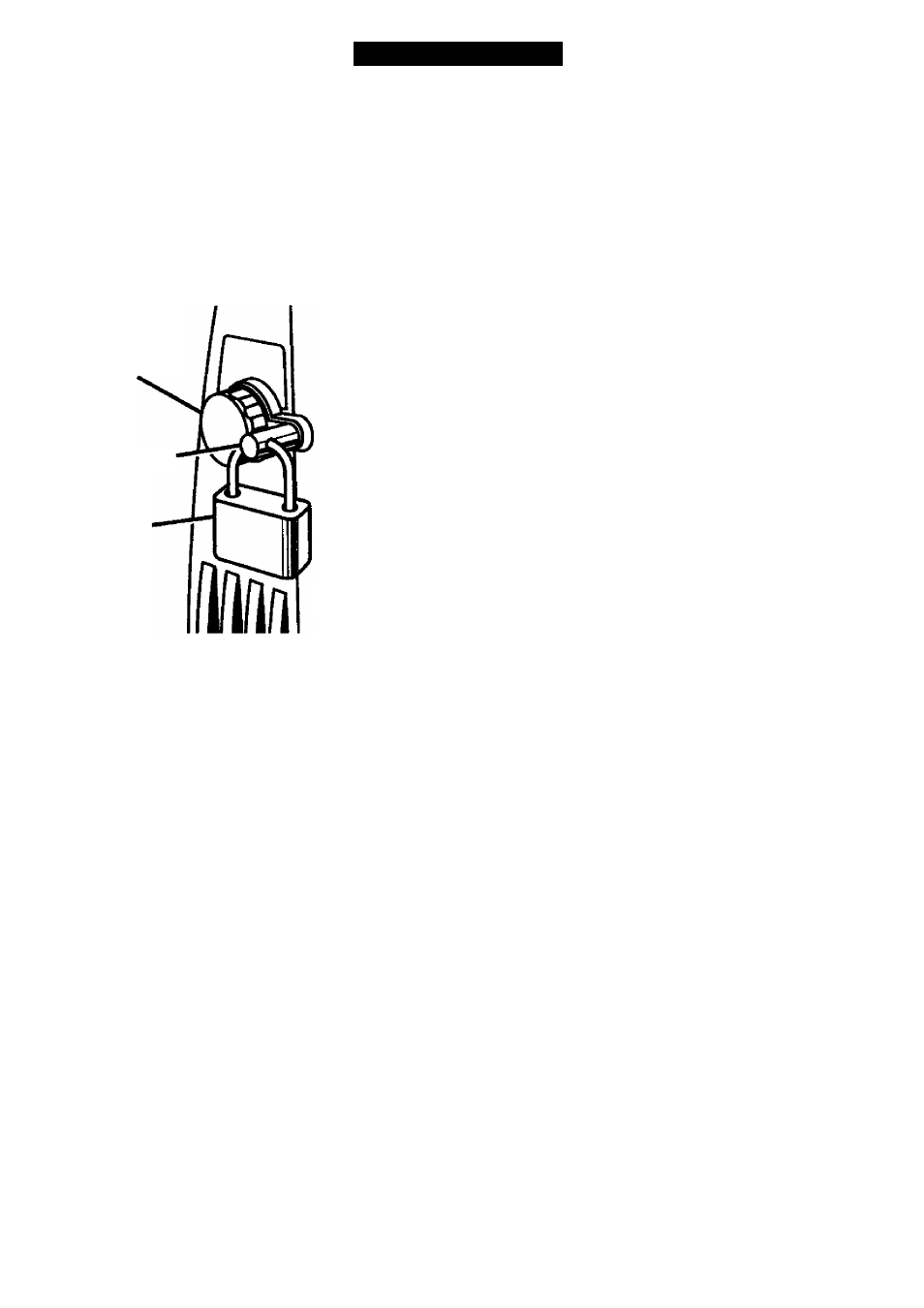

LOCK POST

To prevent unauthorized use of your band saw, we

suggest that you disconnect it from the piower supply

and lock the knob in the

OFF

position. A padlock with

a shackle of 6 mm or 1/4 in. diameter may be used.

When the lock is installed and locked, the switch is

inoperable. Store the padlock key in another location.

■ To lock knob in

OFF

position, install a padlock

through the lock post beside the knob, and lock

the padlock.

ON/OFF KNOB

WITH

VMHABLE SPEED

LOCK POST

PADLOCK

Fig. 23

GENERAL OPERATION

A band saw is basically a "curve cutting” machine. It

can also be used for straight-line cutting operations

such as cross cutting, ripping, mitering, beveling,

compound cutting, and resawing. It is not capable of

making inside or non through cuts.

For general type scroll cutting, follow the pattern lines

by pushing and turning the workpiece at №e same

time. Do not try to turn the workpiece while engaged

in the blade without pushing it or the workpiece could

bind or twist the blade. The blade should cut in the

middle of the pattern line since band saw blades are

thin.

■

Always inspect your band saw for proper adjust

ments before each use.

■

A curved radius cut is best performed by follow

ing the pattern line with the blade while turning

the workpiece.

Use both hands while feeding the work into the

blade. Hold the workpiece firmly against the

table. Use gentle pressure. Do not force the

work, but allow the blade to cut.

The smallest diameter circle that can be cut out

is determined by the width of the blade. A 1/4 in.

wide blade will cut a minimum diameter of

approximately 1-1/2 in. A 1^ in. wide blade will

cut a minimum diameter of approximately 1/2 in.

Relief cuts are made when an intricate curve (too

small a radius for the blade) is to be cut. A relief

cut is made by cutting through the scrap section

of workpiece to curve in pattern line, then care

fully backing blade out. Several relief cuts should

be made for intricate curves, then follow pattern

line as sections are cut off of curve ‘relieving”

blade pressure.

Avoid Injury from unexpected saw move

ment:

Put the saw on a firm level surface with plenty of

room for handling and properly supporting the

workpiece.

Make sure table is level and saw does not rock.

Bolt the saw to the support surface to prevent

slipping, walking or sliding during operations like

cutting long, heavy boards.

Turn saw off, lock with padlock, and unplug cord

before moving the saw.

Avoid Injury from Jams, slips or thrown

pieces:

Choose right size and style blade for material

and the type of cut you (^an to do.

USE ONLY RECOMMENDED ACCESSORIES.

The use of improper accessories may cause risk

of injury to persons.

Make sure the blade teeth point downward,

toward -the table.

Make sure blade guides and thrust bearings are

properly adjusted.

Make sure blade tension is property adjusted.

Make sure table lock knob is tight and no p>arts

have excessive play.

Always adjust the blade guide assembly to just

clear the workpiece to avoid accidental blade

contact, minimize blade breakage and provide

maximum blade support.

19