Craftsman 917.271840 User Manual

Page 21

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

NOTE:

Tlie original equipment battery on

your tractor is maintenance free. Do not

attempt to open or remove caps or covers.

Adding or checking level of electrolyte Is

not necessary.

TO CLEAN BATTERY AND TERMINALS

Corrosion and dirt on the battery and

terminals can cause the battery to Teak”

power.

1. Remove terminal guard.

2. Disconnect BLACK battery cable first

then RED battery cable and remove

battery from tractor.

3. Rinse the battery with plain water and

dry.

4. Clean terminals and battery cable ends

with wire brush until bright.

5. Coat terminals with grease or petroeum

jelly.

6. Reinstall battery (See “REPLACING

BATTERY” in the SERVICE AND

ADJUSTMENTS section of this

manual).

V-BELTS

Check V-belts for deterioration and wear

after 100 hours of operation and replace if

necessary. The belts are not adjustable.

Replace belts if they begin to slip from

wear.

TRANSAXLE COOLING

The transmission fan and cooling fins

should be kept clean to assure proper

cooling.

Do not attempt to clean fan or transmission

while engine is running or while the

transmission is hot. To prevent possible

damage to seals, do not use high pressure

water or steam to clean transaxTe.

• Inspect cooling fan to be sure fan blades

are intact and clean.

• Inspect cooling fins for dirt, grass

clippings and other materials. To prevent

damage to seals, do not use compressed

air or nigh pressure sprayer to clean

cooling Tins.

TRANSAXLE PUMP FLUID

The transaxle was sealed at the factory

and fluid maintenance Is not required for

the life of the transaxle. Should the

transaxle ever leak or require servicing,

contact your nearest authorized sen/ice

center/department.

ENGINE

LUBRICATION

Only use high quality detergent oil rated

with API service classification SF-SJ.

Select the oil’s SAE viscosity grade

according to your expected operating

temperature.

SAE viseosiTv omoEe

TPiWWTiwiwiM>wictWTEOWo<»N№qLCHiwoe

NOTE:

Although multi-viscosity oils

(5W30,10W30 etc.) improve starting in

cold weather, these multi-viscosity oils will

result in increased oil consumption when

used above 32°F. Check your engine oil

level more frequently to avoid possible

engine damage from running low on oil.

Change the oil after every 25 hours of

operation or at least once a year if the

tractor is not used for 25 hours in one year.

Check the crankcase oil level before

starting the engine and after each eight (8)

hours of operation. Tighten oil fill ca^

dipstick securely each time you check the

oil level.

TO CHANGE ENGINE OIL

Determine temperature range expected

before oil change. All oil must meet API

service classification SF-SJ.

* Be sure tractor is on level surface.

* OH will drain more freely when warm.

* Catch oil In a suitable container.

1. Remove oil fill cap/dipstick. Be careful

not to allow dirt to enter the engine

when changing oil.

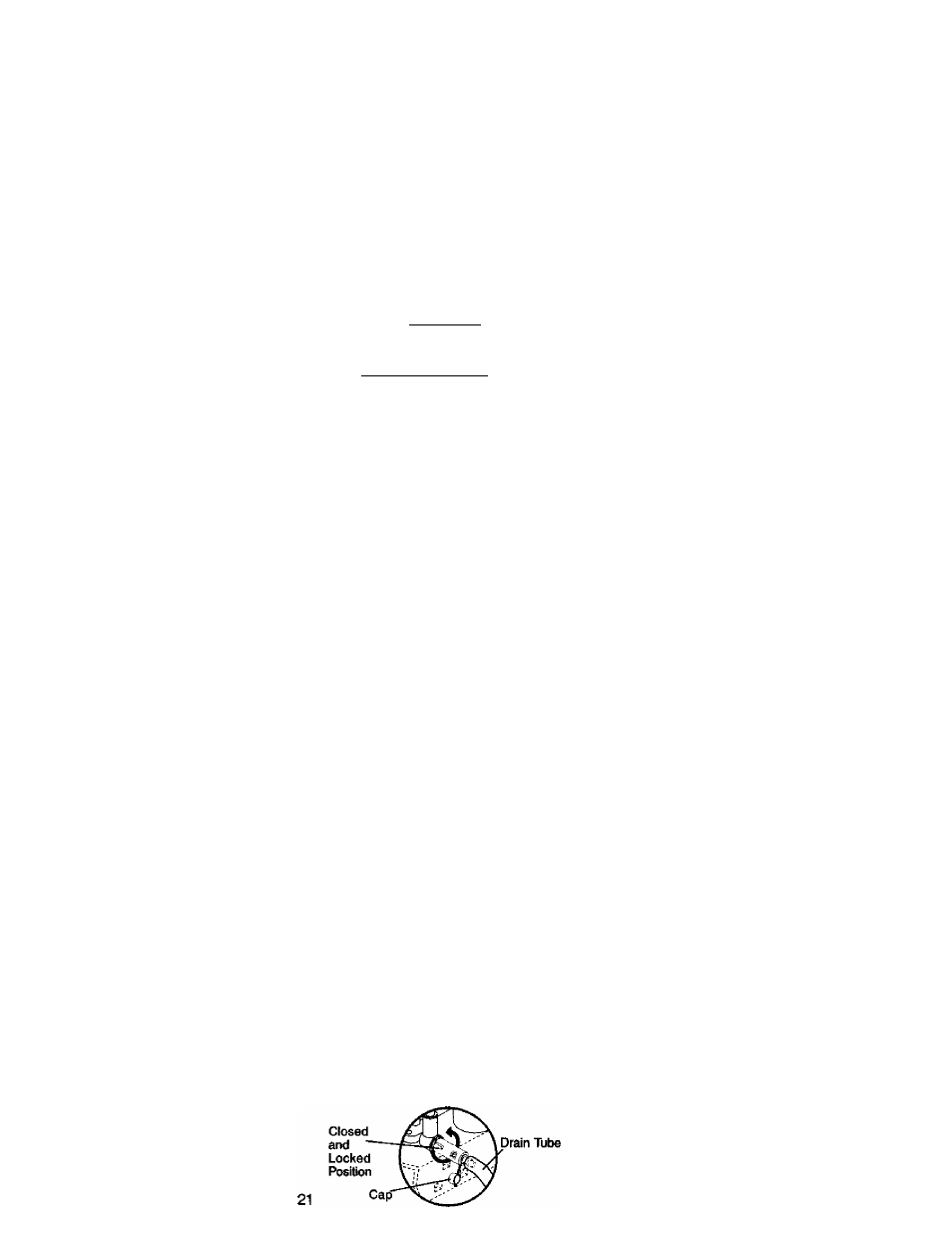

2. Remove cap from end of drain valve

and Install the drain tube onto the

fitting.

3. Unlock drain valve by pushing inward

slightly and turning counterdociwise.

4. To open, pull out on the drain valve.

5. After oil has drained completely, close

and lock the drain valve by pushing

inward and turning clockwise until the

pin is in the locked position as shown.

6. Remove the drain tube and replace the

cap onto to the end of the drain valve.

7. Refill engine with oil through oil fill

dipstick tube. Pour slowly. Do not

overfill. For approximate capacity see

“PRODUCT SPECIFICATIONS" section

of this manual.

8. Use gauge on oil fill cap/dipstick for

checking level. Be sure dipstick cap is

tightened securely for accurate

reading. Keep oil at “FULL” line on

dipstick.

OH Drain Valve