Troubleshooting chart – Craftsman 390.251883 User Manual

Page 9

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

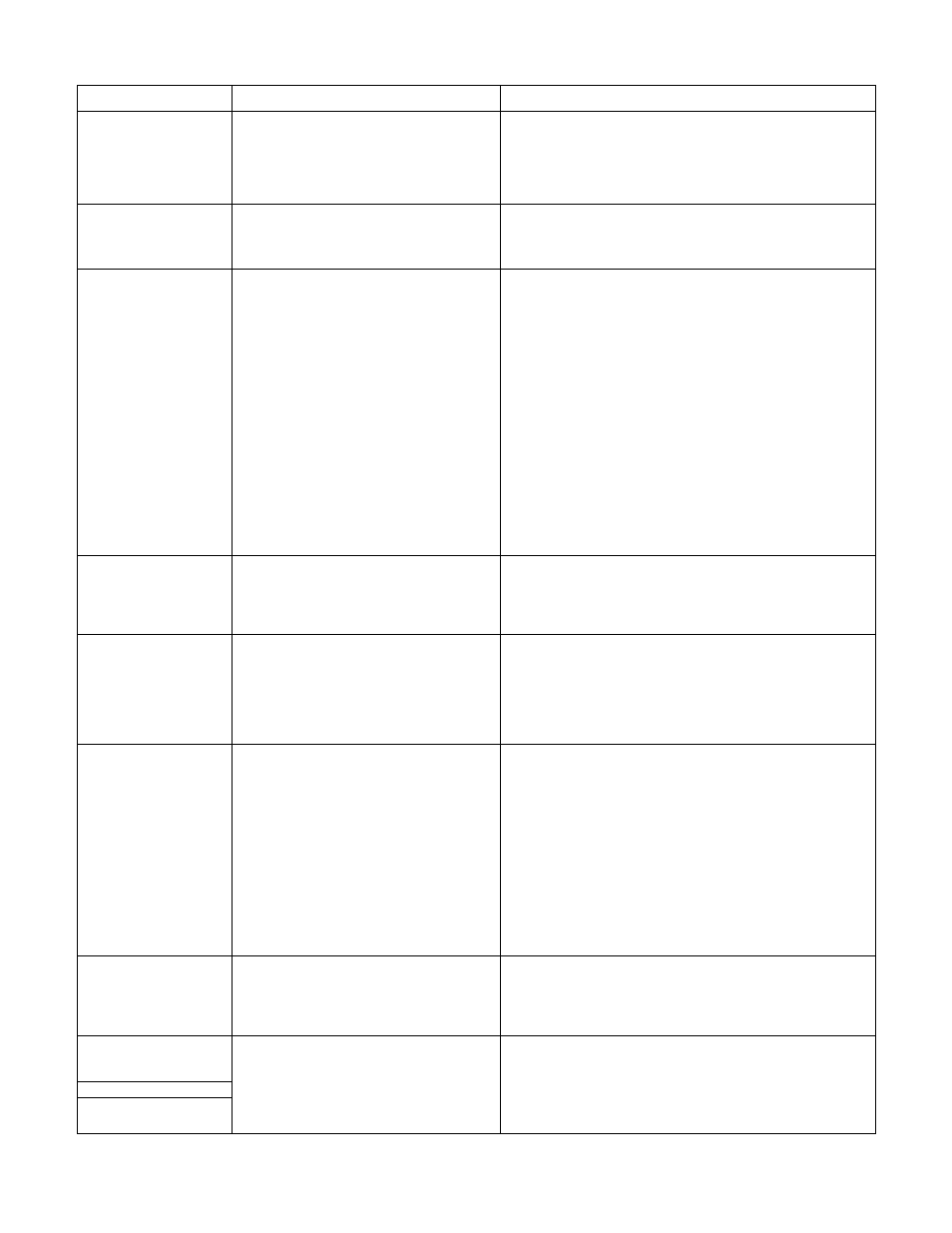

TROUBLESHOOTING CHART

PROBLEM

POSSIBLE CAUSES

REMEDIES

Motor will not run.

1. Disconnect switch is off.

1. Be sure .switch is on.

2. Fuse is blown.

2. Replace fuse.

3. Starting switch is defective.

3. Replace starting switch.

4. Wires at motor are loose,

4. Refer to instructions on wiring.

disconnected, or wired incorrectly.

, Check and tighten all wiring.

5. Pressure switch contacts are dirty.

5. Clean by sliding piece of plain paper between contacts.

Motor runs hot and

1. Motor is wired incorrectly.

1. Refer to Instructions on wiring.

overload kicks off.

2. Voltage is too low.

2. Check with piower company. Install heavier wiring

if wire size is too small. See wiring instructions.

3. Pump cycles too frequently.

3. See section below on too frequent cycling.

Motor runs but no

1. Pump in a new installation did

1. In new installation:

water is delivered.

not pick up prime through;

a. Improper priming.

a. Re-prime according to instructions.

b. Air leaks.

b. Check all connections on suction line, air volume

control, and jet.

c. Leaking foot valve.

c. Replace foot valve.

2. Pump has lost its prime through:

2. In installation already in use;

a. Air leaks.

a. Check all connections on suction line, air volume

contnti, jet and shaft seal.

b. Water level below suction of pump.

b. Lower suction Une into water and re-prime. If receding

water level in a shallow well operation exceeds

suction lift, a deep well pump is needed.

3. Jet or impeller is plugged.

3. Clean jet or impeUer according to instructions.

4. Check valve or foot valve is stuck

in closed position.

4. Replace check valve or foot valve.

5. Pipes are frozen.

5. Thaw pipes. Bury pipes below frost line. Heat pit or

pump house.

6. Foot valve and/or strainer are

6. Raise ftxrt valve and/or strainer above well bottom.

buried in sand or mud.

Pump does not

]. Water level in well is lower than

1. A deep well jet pump may be needed

deliver water to full

estimated.

(over 20 ft. to water).

capacity (also check

2. Steel piping (if used) is corroded or

2. Replace with plastic pipe where possible, otherwise with

point 3 inuncdiatcly

limed, causing excess friction.

new stetd pipe.

above).

3. Offset piping is too small in size.

3. Use larger offset piping.

Pump pumps water

1. Pressure switch is out of adjustment

1. Adjust or replace pressure switch.

but does not shut off.

or contacts are “frozen”.

2. Faucets have been left open.

2. Close faucets.

3. Jet or impeller is clogged. ,

3. Clean jet or impeller.

4. Water level in well is lower than

estimated.

4. Check for possibUity of using a deep weU jet pump.

5. Motor is wired incorrectly.

5. Refer to instructions on wiring..

Pump cycles too

1. Standard pressure tank is water-

1. Drain tank to air volume control tapping. Check air

frequently.

logged and has no air cushion.

volume ct>ntrol for defects. Check for air leaks at any

connection.

2. Pipes leak.

2. Check connections.

3. Faucets or valves are open.

3. Close faucets or valves.

4. Foot valve leaks.

4. Replace foot valve.

5. Pfessure switch is out of adjustment.

5. Adjust or replace pressure switch.

6. Air charge too low in Captive Air®

6. Disconnect electrical power and open faucets until all

Tank. Model 390.251483

pressure is reUeved. Using automobile tire pressure gauge.

and Model 390.251883 require

check air pressure in tank at the valve stem located at top

40 pounds for proper operation.

of tank, [f air pressure is lower, pump air into tank from

outside source, until proper air pressure is reached.

Check air valve for leaks, using soapy solution, and

replace i:ore if necessary. '

Air spurts from

1. Pump is picking up prime.

1. As soon as pump picks up prime, all air will be ejected.

faucets.

2. Leak in suction side of pump.

2. Check suction piping.

3- Well is gaseous.

3. Change installation as described in manual.

4. Intermittent over-pumping of well.

4. Lower foot valve if possible, otherwise restrict discharge

side of pump.

Leaks at the metal

1. Loose clamps or ORing

1. Release alt system pressure before working on clamp.

clamps.

not sealed.

2. Check tliat clamp is tight.

3. Tap around clamp with hammer on a wooden block.

A WARNING

Retighten clamp screw.

Release all pressure in system

4

.

Check ORing for proper seating and/or dirt on

before working on clamp.

ORing or scat.