Trouble shooting, How to order replacement parts – Craftsman 247.799640 User Manual

Page 18

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

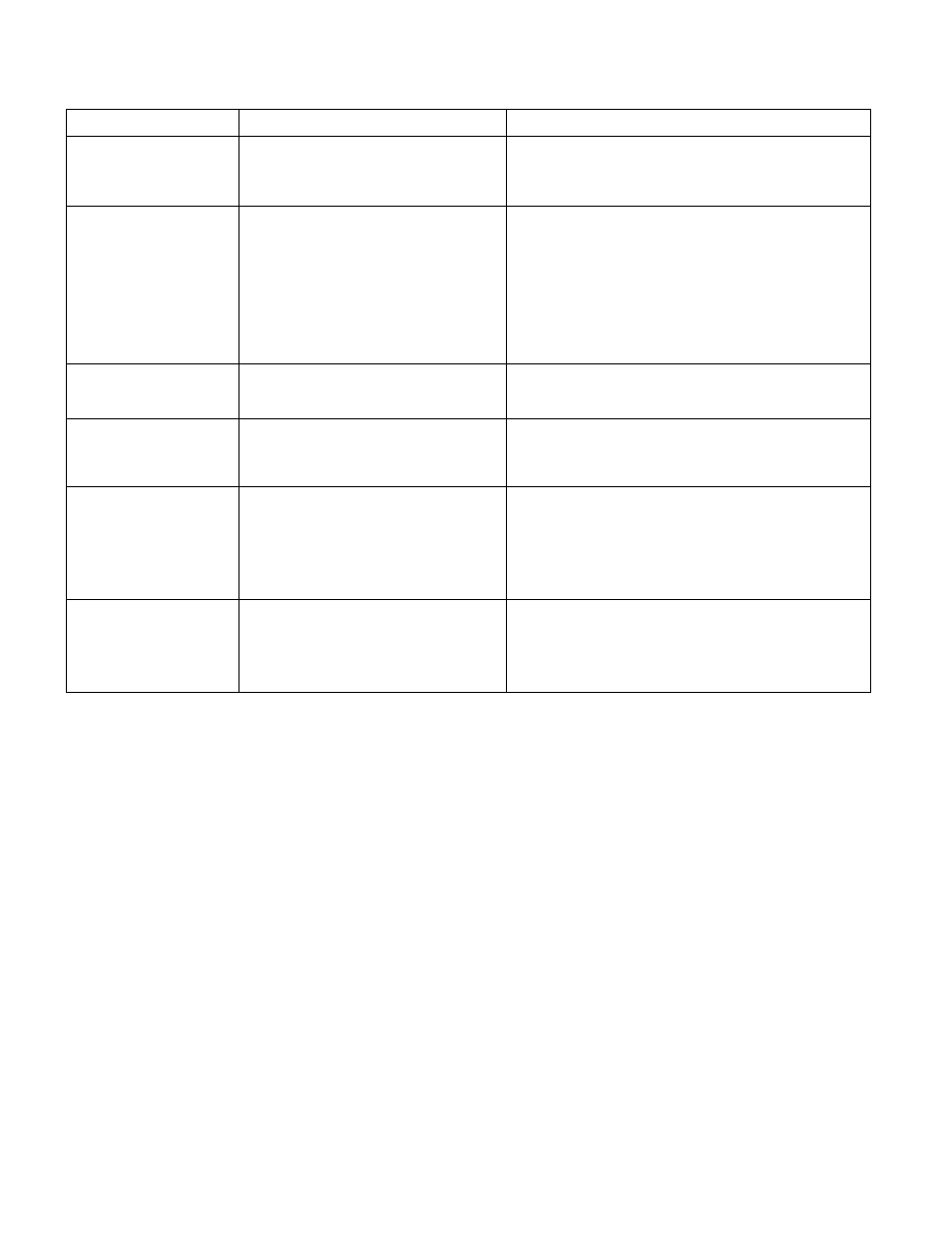

TROUBLE SHOOTING

PROBLEM

POSSIBLE CAUSE(S)

CORRECTIVE ACTION

Engine fails to start

• Fuel tank empty, or stale fuel.

• Spark plug wire disconnected.

• Faulty spark plug.

• Nozzle safety switch not depressed.

• Fill tank with clean, fresh fuel.

• Connect wire to spark plug,

• Clean, adjust gap or replace.

• Adjust metal tab so it depresses the safety switch.

Loss of power;

operation erratic

• Spark plug wire loose.

• Unit running on CHOKE.

• Blocked fuel line or stale fuel.

• Water or dirt in fuel system.

• Carburetor out of adjustment.

• Dirty air cleaner.

• Connect and tighten spark plug wire.

• Move choke lever to OFF position.

• Clean fuel Sine; fill tank with clean

fresh gasoline.

• Disconnect fuel line at carburetor to drain fuel

tank. Refill with fresh fuel.

• Adjust carburetor or contact your SEARS

Service Center.

• Service air cleaner. See Customer Responsibilities

section of this manual.

Engine overheats

• Carburetor not adjusted

properly.

• Engine oil level low.

• Contact your SEARS Service Center.

• Fill crankcase with proper oil.

Too much vibration

• Loose parts or damaged

impeller.

• Stop engine immediately and disconnect

spark plug wire. Tighten ali bolts and nuts.

Make ail necessary repairs. If vibration continues,

have unit serviced by a SEARS Senrice Center,

Unit does not

discharge

• Discharge chute clogged.

• Foreign object lodged in impeller.

• Vacuum bag is full.

• Stop engine immediately and disconnect

spark plug wire. Clean flail screen and inside

of blower housing. See Service/Adjustments

section of this manual.

• Stop engine immediately and disconnect

spark plug wire. Remove lodged object.

• Empty bag.

Rate of discharge

slows considerably or

composition of

discharged material

changes

• Chipper blades dull.

• Sharpen or replace chipper blades.

NOTE: For repairs beyond the minor adjustments listed above, please contact your nearest SEARS Service Center.

HOW TO ORDER REPLACEMENT PARTS

Each chipper-vacuum has its own mode) number.

Each engine has its own model number.

The model number for your chipper-vacuum will be

found on a label attached to the frame.

The model number for the engine will be found on the

blower housing of the engine.

All parts listed herein may be ordered through Sears,

Roebuck and Co. Service Centers and most Retail

Stores.

WHEN ORDERING REPAIR PARTS, ALWAYS GIVE

THE FOLLOWING INFORMATION:

‘PRODUCT - “9 H.P. Chipper-Vacuum”

‘MODEL NUMBER - 247.799640

‘ENGINE MODEL NO. -143.959003

‘PART NUMBER

‘PART DESCRIPTION

Your Sears merchandise has added value when you

consider that Sears has service units nationwide

staffed with Sears trained technicians...professional

technicians specifically trained on Sears products,

having the parts, tools and the equipment to insure

that we meet our pledge to you...“we service what we

sell.”

IF YOU NEED REPAIR

SERVICE OR PARTS;

RE^PAIR SERVIOE

1-800-4-REPAIR

(1-800-473-7247)

ORDERING PARTS

1-800-FON-PART

{1-800-366-7278

18