Pressure washer maintenance, Clean debris, Caution – Craftsman 580.752400 User Manual

Page 14: Check and clean inlet screen, Check high pressure hose, Check gun and nozzle extension, Check in-line filter, Purge pump of air and contaminants, Warning

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

PRESSURE WASHER

MAINTENANCE

Clean Debris

Daily or before use, dean accumulated debris from

pressure washer. Keep linkage, spring and controls

clean. Keep area around and behind muffler free from

any combustible debris.

Pressure washer parts should be kept clean to reduce

the risk of overheating and ignition of accumulated

debris.

CAUTION

Improper treatment of pressure washer c;

damage it and shorten its life.

DO NOT insert any objects through cooling slots.

• Use a damp cloth to wipe exterior surfaces clean.

• Use a soft bristle brush to loosen caked on dirt, oil,

etc.

• Use a vacuum cleaner to pick up loose dirt and debris.

• Use low pressure air (not to exceed 25 psi) to blow

away dirt. Inspect cooling air slots and openings on

the pressure washer. These openings must be kept

dean and unobstructed.

Check and Clean Inlet Screen

Examine garden hose inlet screen. Clean if it is

clogged or replace if it is torn.

Check High Pressure Hose

High pressure hoses can develop leaks from wear,

kinking, or abuse. Inspect hose before each use.

Check for cuts, leaks, abrasions, bulging of cover, or

damage or movement of couplings. If any of these

conditions exist, replace hose immediately.

^ WARNING

The high pressure stream of water that this

equipment produces can pierce skin and its

underlying tissues, leading to serious injury

and possible amputation.

NEVER repair high pressure hose. Replace it.

Replacement hose rating MUST exceed maximum

pressure rating of unit.

Check Gun and Nozzle Extension

Examine hose connection to spray gun and make sure

it is secure. Test trigger by pressing it and making

sure it springs back into place when you release it. Put

trigger lock in UP position and test trigger. You should

not be able to press trigger. Replace spray gun

immediately if it fails any of these tests.

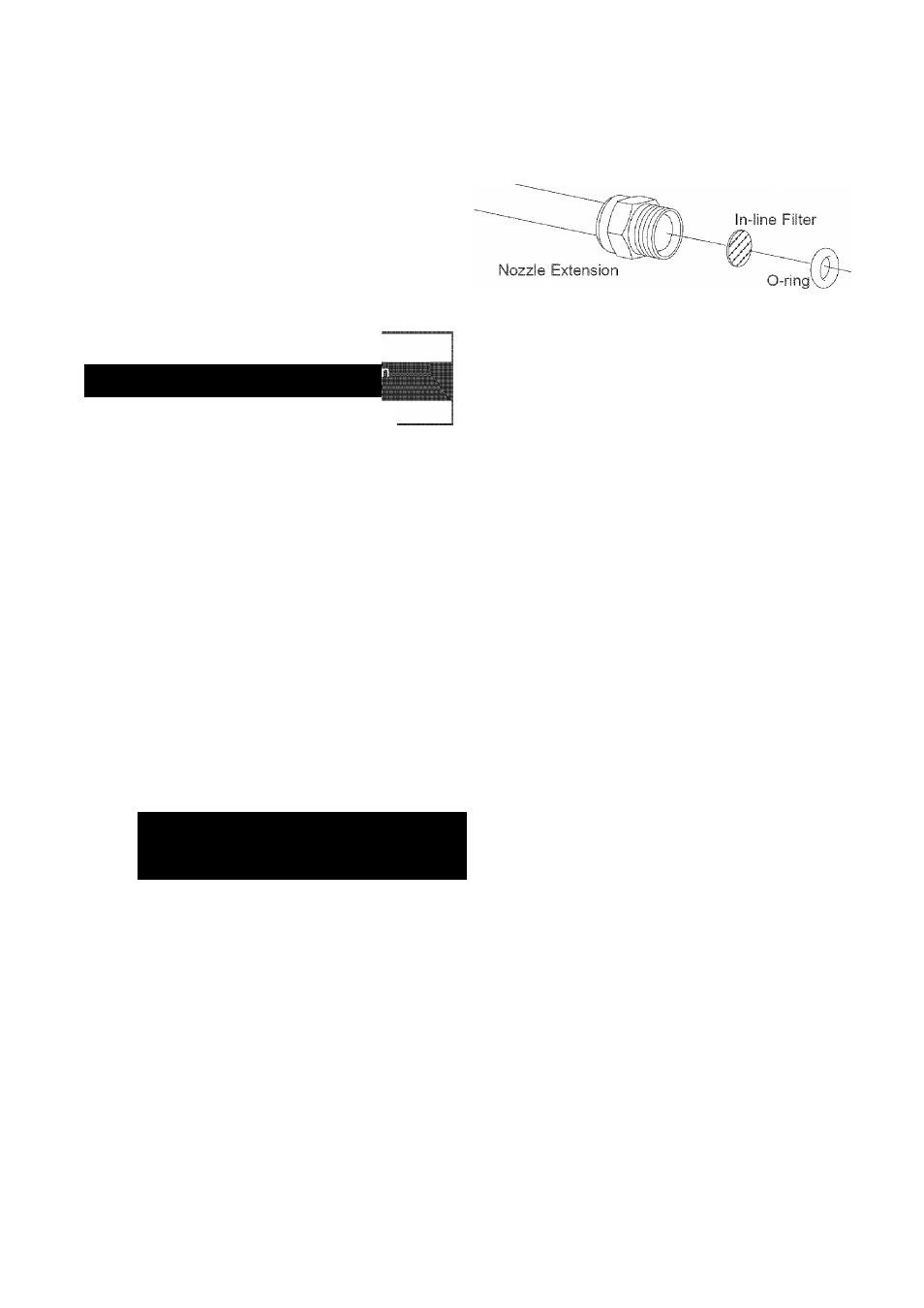

Check In-Line Filter

Refer to the illustration and service the in-line filter if it

becomes clogged, as follows:

1. Detach spray gun from high pressure hose.

Detach nozzle extension from spray gun and

remove o-ring and screen from nozzle extension.

Flush screen, spray gun, and nozzle extension

with clean water to clear debris.

2. Place in-line filter screen into threaded end of

nozzle extension. Direction does not matter. Push

screen in with eraser end of pencil until it rests flat

at bottom of opening. Take care to not bend

screen.

3. Place o-ring into recess. Push o-ring snugly

against in-line filter screen.

4. Assemble nozzle extension to spray gun, as

described earlier in manual.

Purge Pump of Air and Contaminants

To remove air from the pump, follow these steps;

1. Set up pressure washer as described in

"Assembling Your Pressure Washer” section and

connect water supply.

2. Pull trigger on gun and hold until a steady stream

of water appears.

To remove contaminants from the pump, follow these

steps;

1. Set up pressure washer as described in

"Assembling Your Pressure Washer” section, and

connect water supply.

Remove nozzle extension from gun.

2

.

3.

4.

5.

Start engine according to instructions in "How To

Use Your Pressure Washer” section.

Pull trigger on gun and hold.

When water supply is steady and constant,

engage trigger lock and refasten nozzle extension.

14