Adjustmeimts, Warning, Maintenaimce – Craftsman 247.796890 User Manual

Page 9

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

ADJUSTMEIMTS

CARBURETOR ADJUSTMENT

WARNING

If any adjustments are made to the engine -

while the engine if running {eg- car

buretor), keep clear of al! moving parts

Be careful of heated surfaces and muffler.

Minor carburetor adjustment may be required to com

pensate for differences in fuel, temperature, altitude or

load

NOTE

A DIRTY AIR CLEANER WILL CAUSE

ENGINE TO RUN ROUGH. BE CERTAIN

AIR CLEANER IS CLEAN AND ATTACH

ED TO THE

carburetor

before

ADJUSTING CARBURETOR DO NOT

MAKE UNNECESSARY ADJUSTMENTS

FACTORY SETTINGS ARE SATISFAC

TORY FOR MOST APPLICATIONS AND

CONDITIONS.

Never attempt to change maximum engine speed It is

pre-set at the factory and should be changed only by

a qualified service technician who has the necessary

equipment,

The carburetor may need re-adjusting if engine lacks

power or does not idle properly If adjustments are

needed, proceed as follows.

To Adjust Carburetor:

1.

Close needle valve (See figure 16} clockwise

(Oi' finger tight only Forcing may cause damage.

Then open 1-1/2 turns counterclockwise ik~h)

2. Start engine and allow to warm for five minutes.

3

With throttle in RUN position, close needle valve

clockwise until engine starts to lose speed

{lean mixture) Then slowly open needle valve

counterclockwise ik~N) until engine JUST BEGINS

to run unevenly This mixture should be rich enough

for best performance under load.

4

Place throttle control in IDLE position:

a If engine idles, no further adjustment is

necessary.

b. If engine idles too fast, turn idle speed

adjusting screw counterclockwise until

slower speed is obtained

c If engine dies, turn idle speed adjusting screw

1/4 turn clockwise l/^i Place throttle

control in FAST position arid restart engine,

d Move throttle control to IDLE position If

engine does not idle, repeat step c

Test the engine by operating the chipper-shredder,

If engine lends to stall or die out, it usually

indicates that the mixture is slightly lean and it may

be necessary to open iX">) the needle valve slightly

to

provide

a

richer

mixture

This

richer

mixture may cause a slight unevenness in idling.

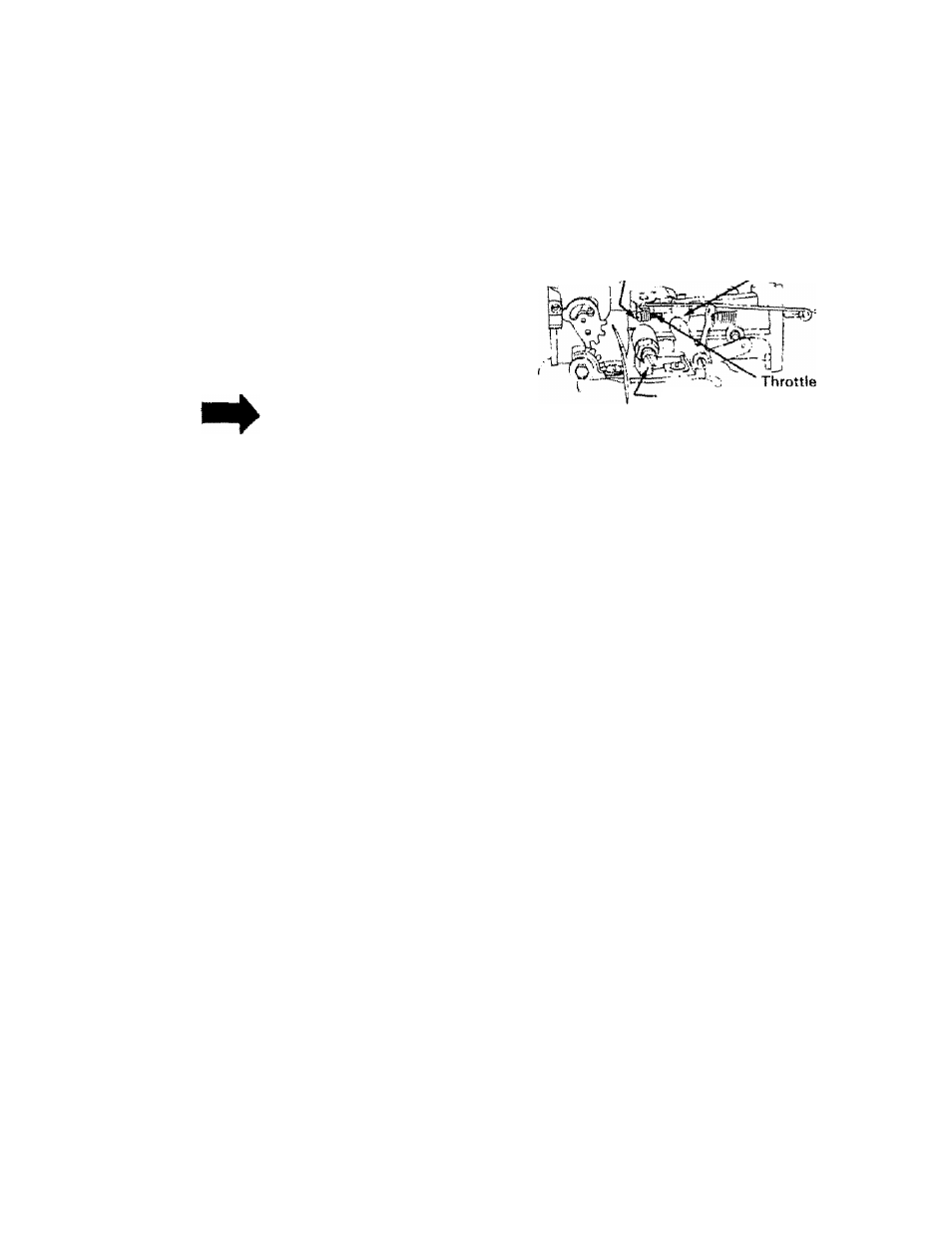

Idle Speed

Adjusting Screw Throttle

Stop

Needle Valve

FIGURE 16.

MAINTENAIMCE

Ac

WARNING

Disconnect spark plug wire and ground

it against the engine before performing

any repairs or maintenance-

ENGINE LUBRICATION

Your four cycle engine will normally consume some oil;

therefore check engine oii level regularly - approxiniateiv

every five hours of operation and before each usage

Stop engine and wait several minutes before checking

oii level, With engine level, the oil must be even with

the oil fill (refer to figure 7) Change engine oil after the

first two hours of operation, and every twenty five

hours thereafter

1. Drain oil while engine is warm

a. Remove oil drain plug Refer to figure 7

b. Tip the chipper-shredder forward, and catch oil

in a suitable container

c. When engine is drained of all oil. replace drain

plug securely.

2 Refill with fresh oil Above 32°, use oil labeled

SAE 30W or 10W30 Below 32°, use oil labeled

5W20 Capacity is 1-1/4 pints Refer to "Gas and

Oil Fill-Up" on page 6

3- Replace oil fill plug.