Installing bits, Removing bits, Adjustable torque clutch – Craftsman 973.2748.70 User Manual

Page 10: To adjust torque

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

OPERATION

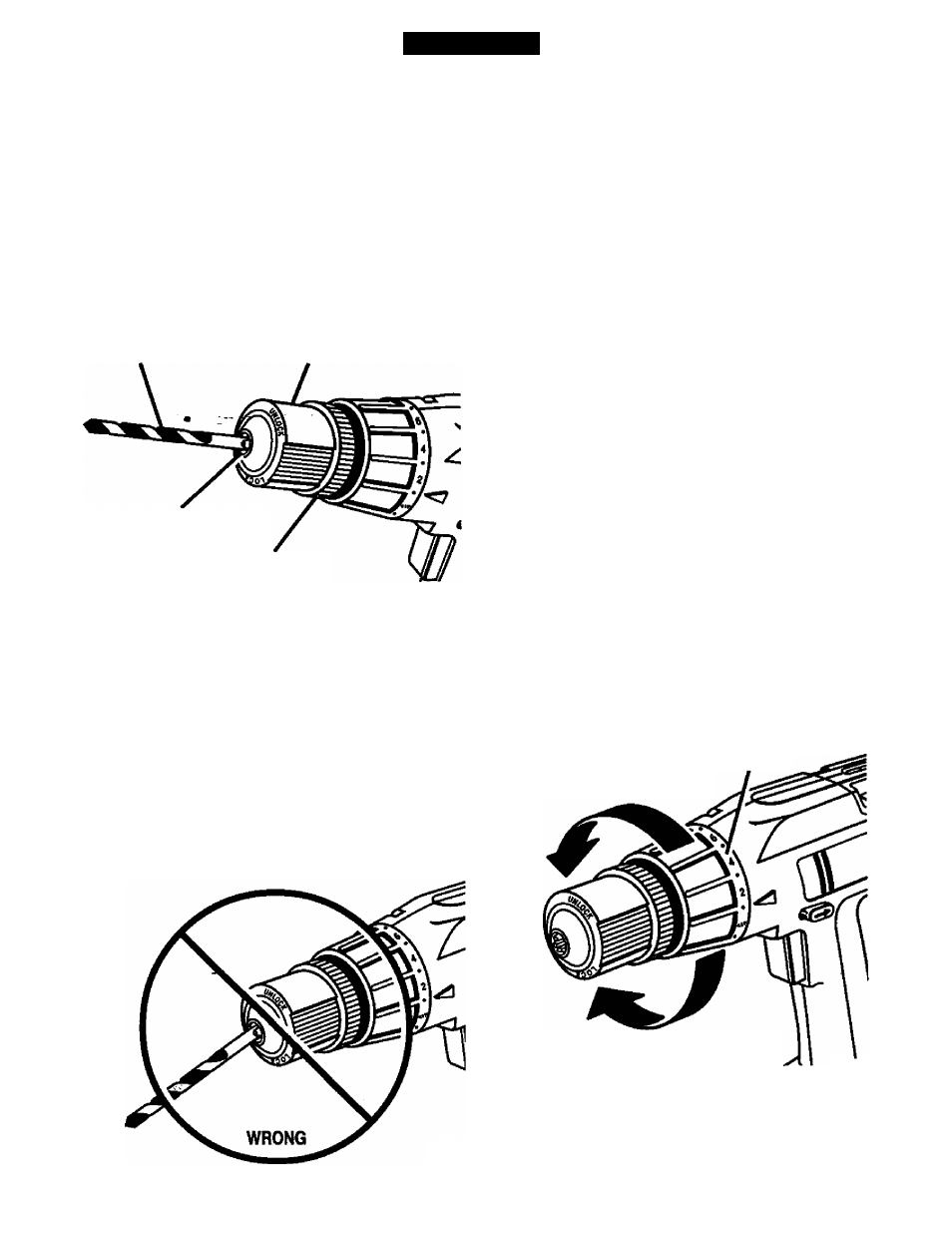

INSTALLING BITS

See Figure 7.

.

.

■

Lock the switch trigger by placing the direction of

rotation selector in center position. See Figure 2.

■

Open or close chuck jaws to a point where the

opening is slightly larger than the bit size you

intend to use. Also, raise the front of your drill

slightly to keep the bit from falling out of the chuck

jaws.

■

Insert drill bit into chuck the full length of the jaws

as shown in figure 7.

■ Tighten the chuck jaws on drill bit.

DRILL err

CHUCK BODY

CHUCKJAWS

CHUCK COLLAR

RIGHT

Fig. 7

To tighten the chuck jaws on drill bit; grasp and

hold the collar of the chuck with one hand, while

rotating the chuck body with your other hand.

Note: Rotate the chuck body in the direction of

the arrow marked LOCK to tighten chuck jaws.

Do not use a wrench to tighten or loosen the

chuck jaws.

. WARNING:

Do not insert drill bit into chuck

* jaws and tighten as shown in figure 8. This could

cause drill bit to be thrown from drill resulting in

possible serious personal injury or damage to the

chuck.

REMOVING BITS

See

Figure 7.

■ Lock the switch trigger by placing the direction of

rotation selector in center position.

See Figure 2.

■ Loosen the chuck jaws from drill bit.

■ To loosen: grasp and hold the collar of the chuck

with one hand, while rotating chuck body with your

other hand.

Note:

Rotate chuck body in the

direction of the arrow marked

UNLOCK

to loosen

chuck jaws.

■ Do not

use a wrench to tighten or loosen the

chuck jaws.

■ Remove drill bit from chuck jaws.

ADJUSTABLE TORQUE CLUTCH

Your drill is equipped with an adjustable torque clutch

for driving different types of screws into different mate

rials. The proper setting depends on the type of mate

rial and the size of screw you are using.

TO ADJUST TORQUE

■ Identify the twenty four torque indicator settings

located on the front of your drill.

See Figure 9.

■ Rotate adjusting ring to the desired setting.

• 1-4 For driving small screws.

• 5-8 For driving screws into soft

material.

• 9 - 1 2 For driving screws into soft and hard

materials.

• 13 -16 For driving screws in hard wood.

• 17 - 20 For driving large screws.

• 21 - 24 For heavy drilling.

TO DECREASE

TORQUE

ADJUSTING

RING

TO INCREASE

TORQUE

Fig. 9

Rg.8

10