Important, Do not remove this bag or destroy the contents, Replace contents in bag – FRIGIDAIRE FGIF3061NF User Manual

Page 3: Service data sheet, Schematic diagram

316904473 Rev A (1303)

IMPORTANT

DO NOT REMOVE THIS BAG

OR DESTROY THE CONTENTS

WIRING DIAGRAMS AND SERVICE

INFORMATION ENCLOSED

REPLACE CONTENTS IN BAG

Electronic Surface Element Control (ESEC)

This range is equipped with an Electronic Surface Element

Control (ESEC), which precisely controls the smoothtop elements

at multiple settings. The warmer zone is not controlled by the

ESEC. For the user, the elements are operated by pushing in and

turning the knobs to the desired settings. The control settings are

shown in 2-digit displays above each knob.

Hot Surface display message (HE) - If any of the induction

elements are hot, the hot surface message "HE" will display and

remain ON until the cooktop cools.

ESEC lockout feature (--) - The electronic oven control's

self-clean and Cooktop Lockout features will not operate when

a surface element is ON. Conversely, the surface elements

controlled by the ESEC will not operate when an oven control

self-clean or Cooktop Lockout mode is active. When the oven

control is in a self-clean or Cooktop Lockout mode, "--" will

appear in the ESEC displays to signify that the surface heating

elements are locked out.

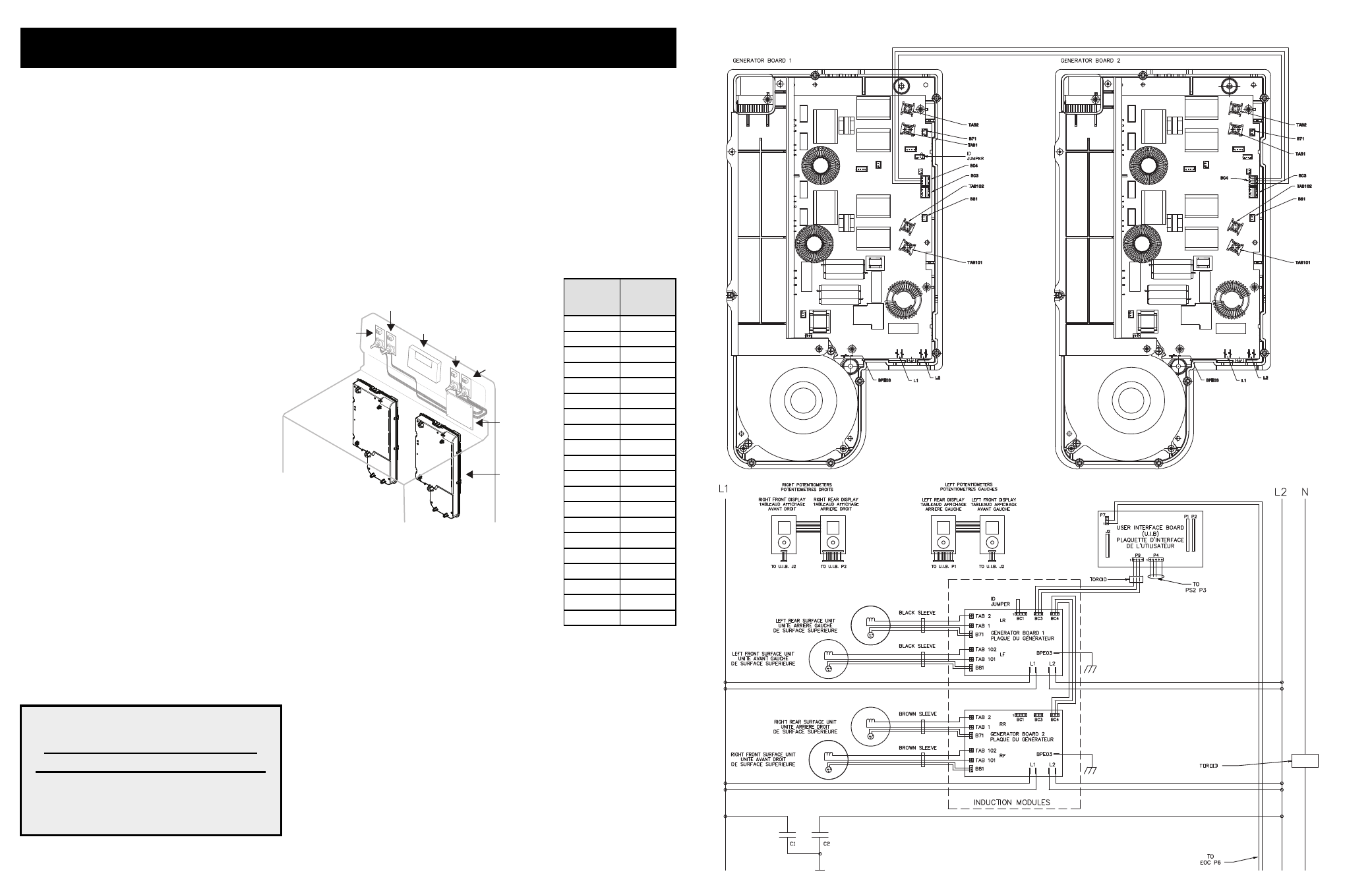

ESEC system components

The ESEC system consists of the following components:

UIB or User Interface Board - this circuit board is mounted with

screws and stand-offs in the backguard.

Potentiometer display boards - push-to-turn controls and

cooktop displays for each element and connections to the UIB.

ESEC harness connects the ESEC system components and

communicates with the EOC (Electronic Oven Control).

Induction control assembly - circuit boards in plastic housings

mounted on the range back side, on two brackets with four

screws.

SERVICE DATA SHEET

Electric Ranges with ESEC20 and Induction Smooothop

Induction Controls Wiring/Connections

Notes on replacing parts

Replacing an induction control assembly*

When replacing an induction control assembly on the back of the

range, do not over-tighten the 2 screws that secure each Control

Assembly to the range or the screws that secure the rear wire

shield to the Control Assembly. Over-tightening the screws can

damage the plastic housings holding the circuit boards.

ESEC with Induction Cooktop

NOTICE

-

This service data sheet is intended for use by persons having electrical and mechanical training and a level of knowledge of these subjects

generally considered acceptable in the appliance repair trade. The manufacturer cannot be responsible, nor assume any liability for injury or damage of

any kind arising from the use of this data sheet.

SAFE SERVICING PRACTICES

To avoid the possibility of personal injury and/or property damage, it is important that safe servicing practices be observed. The following are examples, but without

limitation, of such practices.

1.

Before servicing or moving an appliance remove power cord from electrical outlet, trip circuit breaker to OFF, or remove fuse.

2.

Never interfere with the proper installation of any safety device.

3.

GROUNDING: The standard color coding for safety ground wires is GREEN or GREEN WITH YELLOW STRIPES. Ground leads are not to be used as current

carrying conductors. It is extremely important that the service technician reestablish all safety grounds prior to completion of service. Failure to do so

will create a potential safety hazard.

4.

Prior to returning the product to service, ensure that:

• All electric connections are correct and secure.

• All electrical leads are properly dressed and secured away from sharp edges, high-temperature components, and moving parts.

• All uninsulated electrical terminals, connectors, heaters, etc. are adequately spaced away from all metal parts and panels.

• All safety grounds (both internal and external) are correctly and securely reassembled.

Displayed

Power

Level

Power

Level %

Lo

3.0

1.5

4.25

2.0

5.5

2.5

7.5

3.0

10.5

3.5

13.0

4.0

15.5

4.5

18.0

5.0

21.0

5.5

25.0

6.0

31.0

6.5

38.0

7.0

45.0

7.5

50.0

8.0

54.0

8.5

59.0

9.0

64.0

9.5

80.0

Hi

100

Pb

125-141

Replacing an induction element

Whenever replacing any induction element use only the screws supplied with the range to secure

the element to the mounting panel. Never use any other type of screw to attach the induction

element .

Replacing the potentiometer/display boards*

Each of the four push-to-turn controls (potentiometer/display boards) are mounted to the control

panel with a hex nut and lockwasher. When replacing a potentiometer, do not over-tighten the hex

nut - a torque of only 8 in-lb is required to properly mount the potentiometer.

NOTE: Both potentiometer/display boards must be replaced in pairs (LH or RH sides) at the same

time.

Replacing the UIB*

When replacing the UIB in the backguard, DO NOT over tighten the screws that secure the UIB.

To secure the UIB use NO MORE THAN 20 in. - lbs. Over tightening these screws can possibly

damage the UIB board.

* Please note: Electronic boards are very sensitive to static electricity. Static electricity can

permanently damage electronic boards. Before handling these parts, be sure to drain static

electricity from your body by properly grounding yourself.

LF POTENTIOMETER/

DISPLAY BOARD

LR POTENTIOMETER/

DISPLAY BOARD

RR POTENTIOMETER/

DISPLAY BOARD

RF POTENTIOMETER/

DISPLAY BOARD

USER

INTERFACE

BOARD (UIB)

ELECTRONIC OVEN

CONTROL (EOC)

INDUCTION

CONTROL

ASSEMBLY

SCHEMATIC DIAGRAM

- 30 Inch Front Control Electric Range Wiring Diagram FFEF3017ZW FFEF3018LB FFEF3018LW FFEF3048LS FFEF3018LM FFEF3018LQ FGGF3032MF FGGF3032MB FGGF3032MW FFED3015PB FFED3025PS FFES3025PB FFED3025PB FFED3015PW FFES3025PW FFES3025PS FFED3025PW FFES3015PW FFES3015PB FFES3015PS FFEF3050LS FFEF3019MS ES 1000 316905023