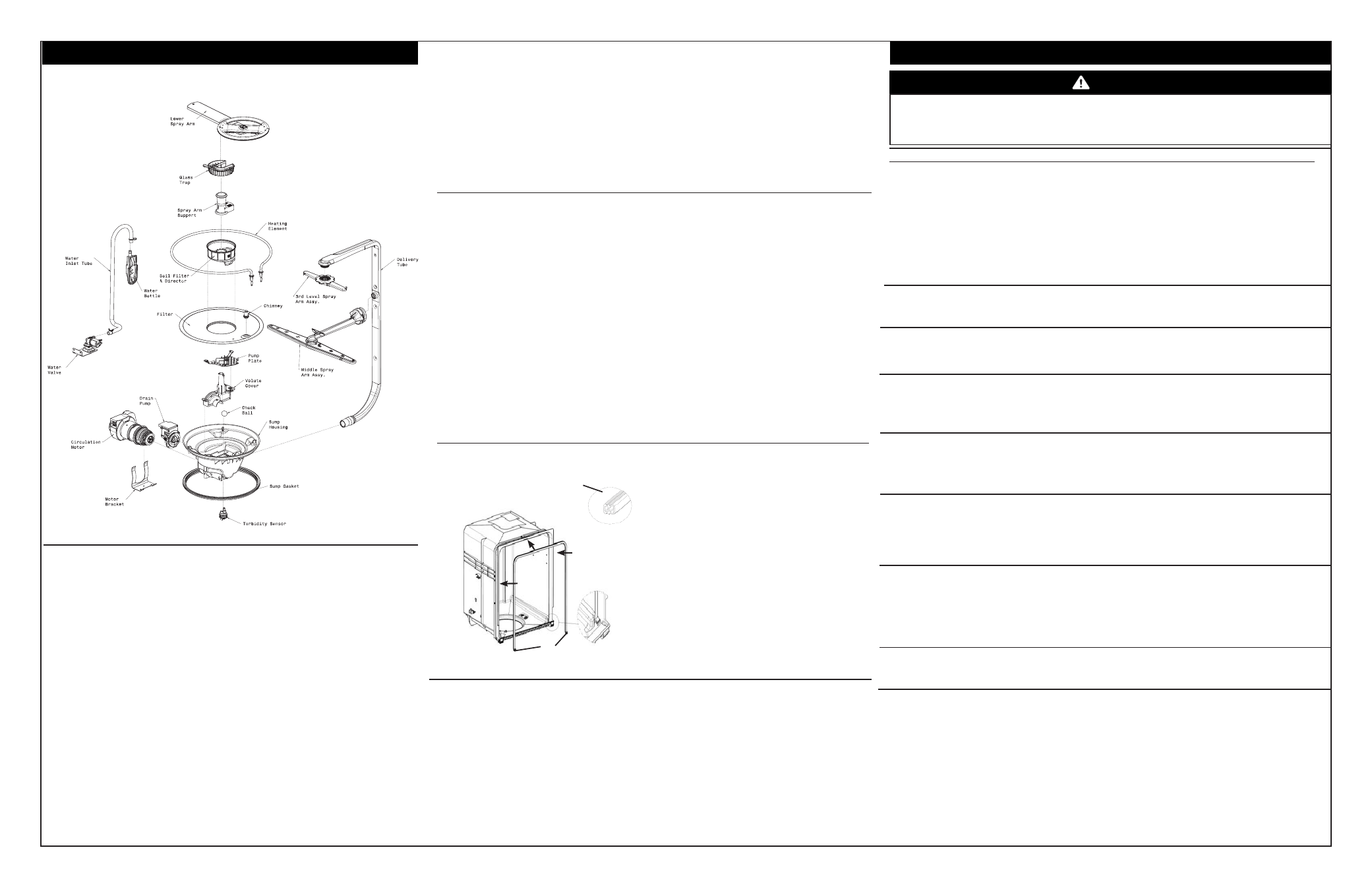

Trouble shooting tips, Exploded view of wash system, Warning – FRIGIDAIRE FGID2466QB User Manual

Page 2: Pump assembly, Detergent and rinse, Standard dry air flow tub and door seal, Product specifi cations

The heating element at the bottom

of the tub and the vent assembly in

the top right rear of the tub are used

to dry dishware. During the “dry”

portion of the cycle the heater, the

solenoid that opens the vent’s damper

and the vent fan are energized. The

vent fan draws in cooler, drier air from

outside the tub and pushes it down

into the tub. Hot moist air rises to

TROUBLE SHOOTING TIPS

Tub Interior

Mounting Rib

Pump Assembly

The drain hose must have a loop at

a minimum height of 32 inches

in order to insure proper drainage.

To remove the main circulation

(circ) pump do the following in

sequence: Shut off electricity to the

dishwasher. Disconnect the wiring

harness connections located at the

circ pump’s motor. Remove the two

screws that hold the motor bracket.

Slide the motor bracket away from

the sump. The motor and pump,

now held only by friction against

O-rings, can be pulled out of the

sump.

The pump assembly is driven by a

synchronous motor. Rotation is in the

counterclockwise direction at up to

3600 RPM. The motor drives a pump

which supplies 100 percent fi ltered

water at a rate of approximately 12

GPM to one spray arm at a time. The

spray arm’s operation is alternated by

small “pauses” of the motor during

the wash cycle.

Draining is accomplished by using

a small seperate synchronous drain

pump mounted to the side of the

sump. The drain check valve is

located at the discharge end of

the drain pump. The drain hose is

attached by a worm gear clamp to the

discharge end of the drain pump.

the duct inlet near the top of the door.

At the duct exit near the bottom of the

door drier air escapes into the kitchen

and the condensed water runs into the

drain portion of the dishwasher. Energy

from the heating element warms the

incoming air and augments the energy

stored in the dishware. Together their

energy causes the water on the dishware

to evaporate.

Detergent and Rinse

The detergent and rinse aid dispenser

is a one piece component consisting

of a molded detergent cup and a

built-in rinse aid dispenser.

The detergent cup has a spring

loaded cover and the rinse aid

dispenser has a removeable cover.

To re-fi ll, remove the cap and poor

rinse aid in until the level shows

above the bottom of the cylindrical

opening and the sight gauge changes

appearance. If any is spilled wipe

it up before starting the cycle. The

amount of rinse aid released

can be adjusted by turning the arrow

indicator from one, being the least

amount, to four, being the greatest

amount.

To replace dispenser:

• shut off electricity to dishwasher,

• remover outer door panel assembly,

• disconnect wiring to the actuator,

• remove the six screws,

• remove the dispenser,

• replace and reinstall screws,

• rewire

actuator.

Standard Dry Air Flow

Tub and Door Seal

Symptom

Check the Following

Remedy

Dishwasher will not operate

when turned on.

1. Fuse (blown or tripped).

2. 120 VAC supply wiring

connection faulty.

3. Electronic control board

defective.

4. No 12 VAC power to control.

5. Motor

(inoperative).

6. Door Switch (open contacts).

7. Door latch not making contact

with door switch

8. Touch pad circuit defective.

9. No indicator lamps illuminate

when START or OPTIONS are

pressed.

1. Replace fuse or reset breaker.

2. Repair or replace wire

fasteners at dishwasher

junction box.

3. Replace control board.

4. Replace control board.

5. Replace

motor/impeller

assembly.

6. Replace latch assembly.

7. Replace latch assembly.

8. Replace console assembly.

9. Replace console assembly.

Motor hums but will not

start or run.

1. Motor (bad bearings).

2. Motor stuck due to prolonged

non-use.

1. Replace motor assembly.

2. Rotate motor impeller.

Motor trips out on internal

thermal overload protector.

1. Improper

voltage.

2. Motor windings shorted.

3. Glass or foreign items in pump.

1. Check

voltage.

2. Replace

motor/impeller

assembly.

3. Clean and clear blockage.

Dishwasher runs but will

not heat.

1. Heater element (open).

2. Electronic control board

defective.

3. Wiring or terminal defective.

4. Hi-Limit thermostate defective.

5. Thermistor

failure.

1. Replace heater element.

2. Replace control board.

3. Repair or replace.

4. Replace

thermostat.

5. Replace turbidity sensor.

Detergent cover will not

latch or open.

1. Latch mechanism defective.

2. Electronic control board

defective.

3. Wiring or terminal defective.

4. Broken spring (s).

5. Defective

actuator.

1. Replace

dispenser.

2. Replace control board.

3. Repair or replace.

4. Replace

dispenser.

5. Replace

dispenser.

Dishwasher will not pump

out.

1. Drain

restricted.

2. Electronic control board

defective.

3. Defective drain pump.

4. Blocked

impeller.

5. Open

windings.

6. Wiring or terminal defective.

1. Clear

restrictions.

2. Replace control board.

3. Replace

pump.

4. Check for blockage, clear.

5. Replace pump assembly.

6. Repair or replace.

Dishwasher will not fi ll with

water.

1. Water supply turned off.

2. Defective water inlet fi ll valve.

3. Check

fi ll valve screen for

obstructions.

4. Defective

fl oat switch.

5. Electronic control board

defective.

6. Wiring or terminal defective.

7. Float stuck in “UP” position.

1. Turn water supply on.

2. Replace water inlet fi ll valve.

3. Disassemble and clean

screen.

4. Repair or replace.

5. Replace control board.

6. Repair or replace.

7. Clean

fl oat.

Dishwasher water siphons

out.

1. Drain hose (high) loop too

low.

2. Drain line connected to a fl oor

drain not vented.

1. Repair to proper 32-inch

minimum height.

2. Connect to a vented drain.

Detergent left in dispenser.

1. Detergent allowed to stand too

long in dispenser.

2. Dispenser wet when detergent

was added.

3. Detergent cover held closed or

blocked by large dishes.

4. Improper incoming water

temperature to properly

dissolve detergent.

5. See “Detergent cover will not

open”.

1. Instruct

customer/user

2. Instruct

customer/user

3. Instruct customer/user on

proper loading of dishes.

4. Incoming water temperature

of 120

0

F is required to

properly dissolve dishwashing

detergents.

EXPLODED VIEW OF WASH SYSTEM

Short Turn

Line up the center mark on the back of the

seal with the tub top center and press it

into the channel. Move along the channel

left and right periodically pressing the seal

into place without bunching or stretching it

until going around the corners at the top.

Next, place the free ends into the channel

at the bottom left and right by creating

a short turn at the bottom of the tub

channel and ensuring the seal extends to

the locator ridge at the bottom of the tub

(see enlarged portion of the image at left).

Then, press the seal periodically into place.

Finally slide your fi ngers over the seal to

press it fully in place. When complete a

single face of the seal should be visible

and fl ush with the edge of the channel.

Always disconnect the dishwasher from the electrical power source before adjusting or

replacing components.

Personal Injury Hazard

WARNING

Product Specifi cations

Rating......................................120 Volts, 60Hz

Separate Circuit..15 amp min......- 20 amp max.

Motor (Amps)............................................1.8

Heater Wattage.........................................900

Total Amps (load rated).............................10.0

TempAssure......................................140

0

F

+

5

0

F

(60

0

C

+

3

0

C) [with outer door in place]

TempBoost........................................145

0

F

+

5

0

F

(63

0

C

+

3

0

C) Heated Wash/Heated Rinse

Sanitize.............................150

0

F

+

5

0

F (66

0

C

+

3

0

C)

Hi-Limit Thermostat .......................200

0

F

(93

0

C)

Water Supply

Suggested minimum incoming water

temperature......................................120

Pressure (PSI) min./max...................20/120

Connection..............................3/8” NPT or

3/4” Hose Thread

Consumption (Normal Cycle).......................

4.9 - 9.7 U.S. gal., 18.5 - 36.7

Water valve fl ow rate (U.S.GPM)..............83

Water recirculation (U.S. GPM)....................

approx. 12

Water fi ll time........................................87

-

-

-

Electrical

-

-

-