Periodic testing – Cooper Lighting ELPS502 User Manual

Page 4

3. Test wiring for correctness with continuity checks and also for unwanted grounds with

insulation resistance tester.

4. Allow the ELPS to charge under line power for 72 hours before initiating any testing of

the emergency operation of the lights.

D. Complete Installation

1. Install CID101 corrosion inhibitor device (supplied loose in ELPS50). Recommended

location is on the bottom wall between “Main Power On” pilot light and 1" NPT tapped

hole. Refer to CID101 instructions for installation.

2. Close cover and securely tighten all cover bolts and nuts to 30 ft. lbs. torque making

certain that no cover bolts are omitted. Use only bolts supplied with the enclosure.

NOTE: ELPS units have two stud bolts located at diagonally opposite corners of the

body to aid in positioning cover.

DO NOT depress the push-to-test pushbutton until after the ELPS has been powered

for 72 hours. The emergency battery requires 72 hours to fully charge. The indicating

light will illuminate steadily (no pulsing) when the ELPS is fully charged.

3. Test emergency lighting system for proper operation:

a. Turn on power to designated disconnect switch.

b. Turn on designated disconnect switch and observe:

• “Main Power ON” indicating pilot light should be operating.

• EVLA12 emergency light(s) should be “OFF”.

c. Press “Push-to-Test” indicating push button switch and observe:

• “Main Power ON” light should be “OFF”.

• EVLA12 emergency light(s) should be “ON”.

4. Lock designated disconnect switch “ON” to prevent unauthorized persons from turning

system “OFF”.

5. Adjust EVLA12 emergency light(s) for the desired direction of illumination & lock into

position using 1-5/8” open-ended wrench & torquing to 58 lb.-ft. See Figure 2.

E. Remote Mounting EVLA12 Emergency Light Only

1. Attach the EVLA12 to a Cooper Crouse-Hinds EABC36 or EABL36 1" NPT outlet box.

2. Secure this assembly to the mounting surface with ¼ inch bolts or lag screws of the

required length (not supplied).

3. Refer to Table 1 on page 6 for conductor recommendations.

4. Refer to Sections B for aiming adjustments and section C for Conduit Connections and

Wiring.

PERIODIC TESTING

Article 700 of the National Electrical Code states that, “Systems shall be tested

periodically on a schedule acceptable to the authority having jurisdiction to assure their

maintenance in proper operating condition”. It also states that, “A written record shall be

kept of such tests and maintenance”.

In the absence of periodic testing requirements by a local authority, the following

recommendations from the NFPA 101 (2003) Life Safety Code are strongly recommended:

1. Monthly: Operate “Push-to-Test” switch and keep depressed for a minimum of 30

seconds. Observe that emergency lighting fixtures are on full brightness for the full

time. Record the test on the maintenance record card. Maintenance Record Card is

provided in instruction sheet envelope.

2. Annually: Shut off power at the distribution panel. Verify that the emergency lighting

fixtures remain “ON” for a minimum of 1-1/2 hours.

NOTE: Leave the designated disconnect switch “ON” during this test so that battery

circuit is not interrupted. We suggest that this test be continued until the power supply

automatically shuts the emergency light(s) off. This will help maintain full battery

capacity.

Record the test on the Maintenance Record Card.

Allow 48 hours charging time before depending on the battery to operate at full

capacity.

Failure to function properly in either test may indicate the need for battery or lamp

replacement.

IF 1510 • 05/06

Copyright © 2006, Cooper Industries, Inc.

Page 4

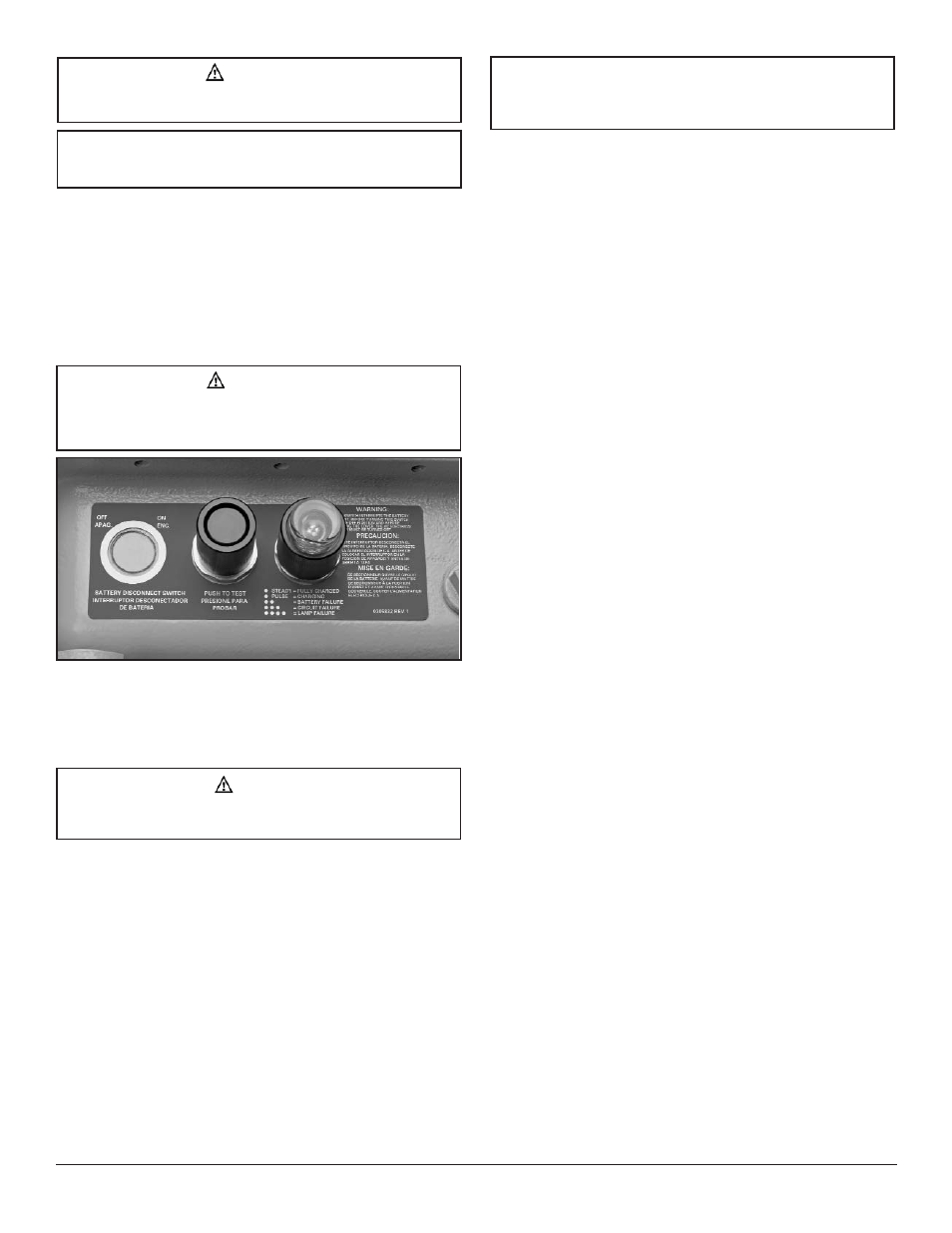

Figure 5. ELPS50 Controls

CAUTION

To avoid explosion, clean both flat joint surfaces of body and cover before closing.

Dirt or foreign material must not accumulate on flat joint surfaces. Surfaces must

seat fully against each other to provide a proper explosion proof seal.

WARNING

To avoid electrical shocks, use fixture only on systems with an equipment

grounding conductor.

NOTE

Unit needs to charge for 72 hours before conducting any tests. Do not disconnect

AC power until unit is fully charged.

NOTE

In Class II and Class III and Simultaneous Presence locations, limit upward

aiming of fixture to a maximum of 30º above horizontal. Greater upward aiming

could lead to excessive dust buildup and dangerous overheating of the dust.

NOTE

A Class I, Division 1 sealing fitting must be installed within 18 inches of the

conduit entry of the ELPS enclosure. Use Chico A or Chico SpeedSeal sealing

compound to seal the conduit entry.