FASS FA C09 220G User Manual

Page 11

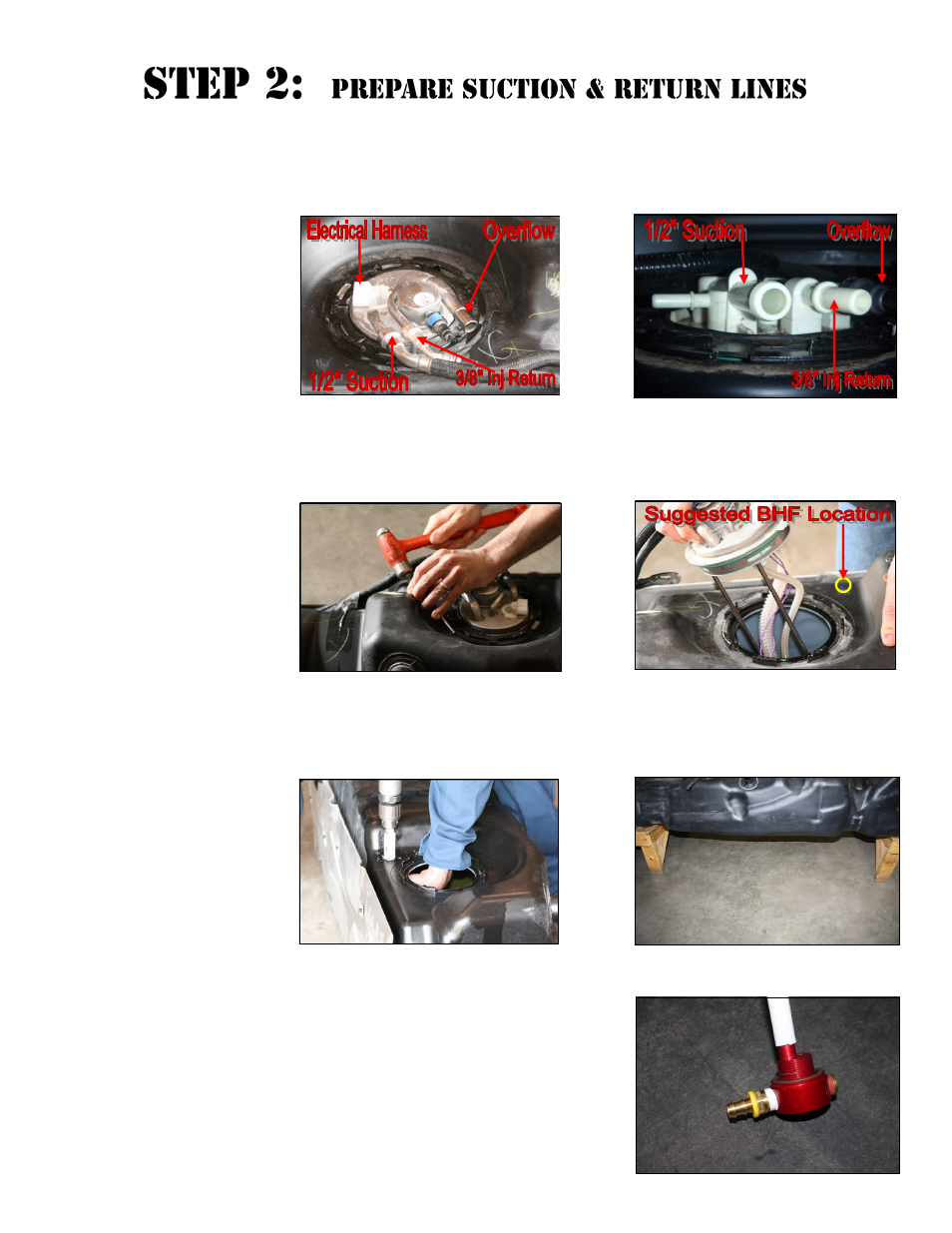

G.

Check fuel tank for good installation location of the suction tube assembly. Remove the lock ring on

top. Mark location of Fuel Module in relation to the tank. Remove Fuel Module. Be careful not to

bend the Fuel Level Arm.

I.

Assemble the BHF-1002 with the PL-1004 in port “S” using thread

tape, the 1/2” plug in port ‘R’. Torque to 40ft/lbs. Push the ST-

1005P onto the barb portion of the BHF-1002. Insert O-ring into

groove.

F.

Disconnect electrical harness. Using disconnect tools, remove factory suction & return lines from fuel

module. Pinch in tabs on 2011-. Disconnect overflow tube. You can now remove the fuel tank.

H.

Using a cup, reach inside the tank under the hole location to catch debris. Drill a 1 3/8” hole. Re-

move debris from top of tank.

Use blocks or something similar to support tank during measure-

ment simulating tank “hanging” by the straps. Failure to do so may result in a short draw tube.

Do Not use sealant on AN (male flare) fittings. Only use sealant on threads installed into pump assembly.

NOTE: Hose clamps are not recommended for push lock fit-

tings. They will hold up to 300psi! Use oil on fittings and inside

fuel line when installing Push-Lok fittings