Humboldt H-1449 Vacuum Extractor User Manual

Page 5

5.4 Mix the bitumen and aggregate by hand until aggregate is thoroughly coated. The

mix specimen shall be kept within the specified job- mix temperature range by

placing it on the hot plate during mixing. The mixing tool shall remain in the beaker

until the specimen is ready to be transferred to the extractor.

5.5 Allow the specimen to cool to less than 130°F. Then add alcohol and methylene

chloride and stir as in section 3.

5.6 Proceed as in section 4, procedure method A, except that the aggregate shall be

dried back to a constant weight at 275°F, ± 5.

CALCULATIONS

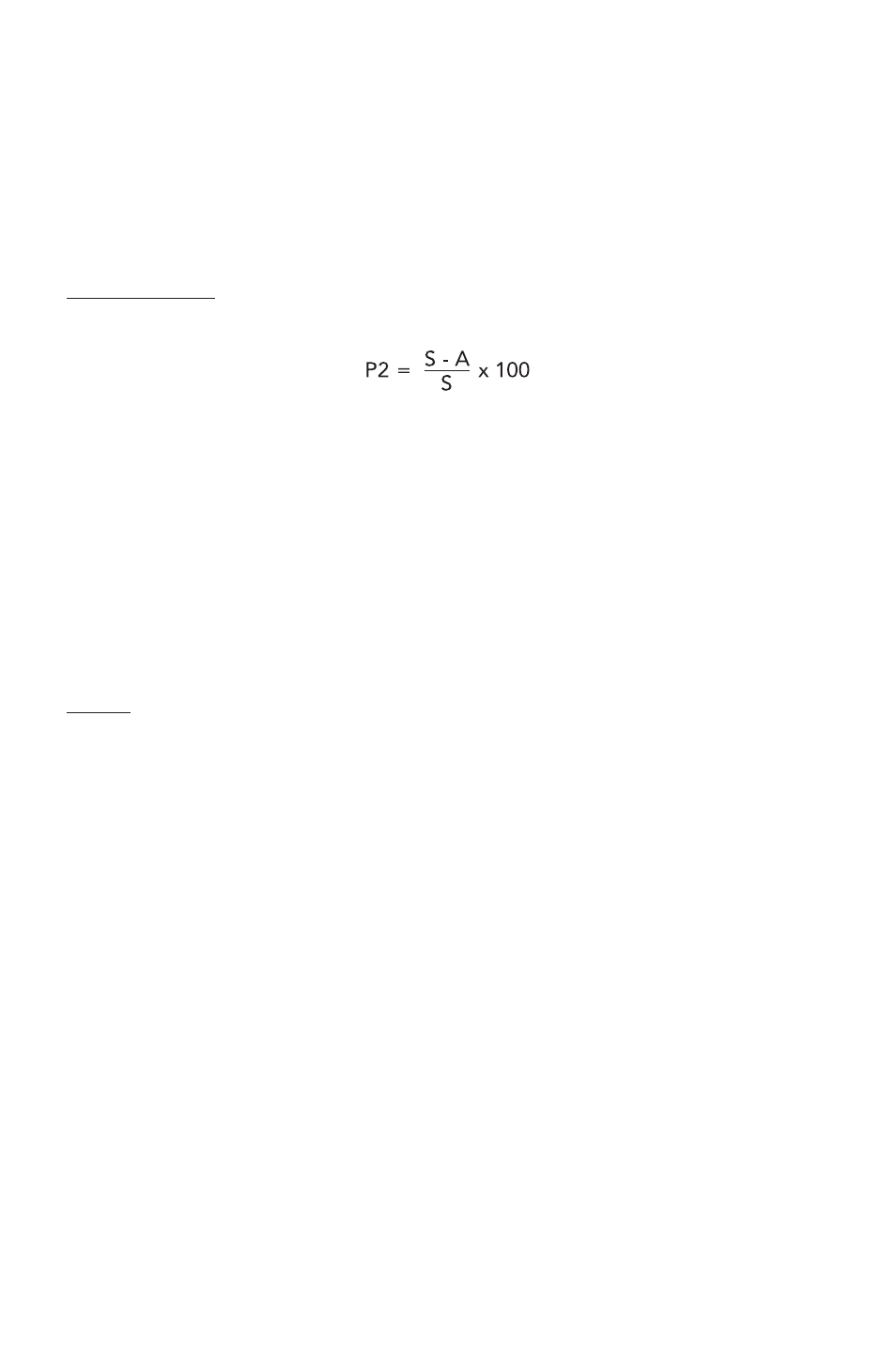

Calculate the percentage of bitumen extracted and the retention factor as follows:

R= P1 - P2

Where:

S= Original weight of mix specimen (dry aggregate plus bitumen added)

A= Weight of extracted mineral aggregate

P1= Percent bitumen added to the mix

P2= Percent bitumen extracted from the mix

R= Retention factor

If there is more than 0.05 percentage points between the two tests, run a third test and

average any within 0.05 of each other.

6. Method B

SCOPE

6.1 This method is to be used on mixes such as those containing hydrated limes that are

very slow filtering.

6.2 Preparation of sample shall be as given in section 3.

6.3 Place a dry tare filter on the vacuum extractor and tighten the wing nuts finger tight.

6.4 Weigh 50 gm of oven-dry celite into a 1000 ml Erlenmeyer flask and add 500 ml of

methylene chloride. Swirl until celite is completely in suspension.

6.5 Immediately pour celite and methylene chloride onto filter, turn on vacuum pump

and let run until pad formed by celite is surface dry and begins to crack slightly.

6.6 Place watch glass in extractor and gently pour solvent onto it; remove it with tongs

and wash with wash bottle, then add the rest of the sample and proceed as in

section 4.2, 4.3 & 4.4 under procedure method A, except in order to find the dry

weight of the Aggregate, subtract the weight of the filter, pan, and the celite from

the total weight.

7. Sieve Analysis (Procedure)

Use the standard method of test for mechanical analysis of extracted aggregate,

AASHTO T30. If celite is used as in method B, no correction need be made as celite is all

minus No. 200 mesh and will be lost in the wash process.