Maintenance – Humboldt H-1322B Marshall and TSR Compression Machine User Manual

Page 8

Using a ½" hex socket on a

3

/

8

" drive ratchet, connect to the

internal male hex shaft and crank counter clockwise to raise the

platen and apply load to the reference gage and the machine’s

load

cell .

Starting from the chart origin, observe the recorder's pen position

and check it against the reference gage reading for each 1000 lbf

of load applied .

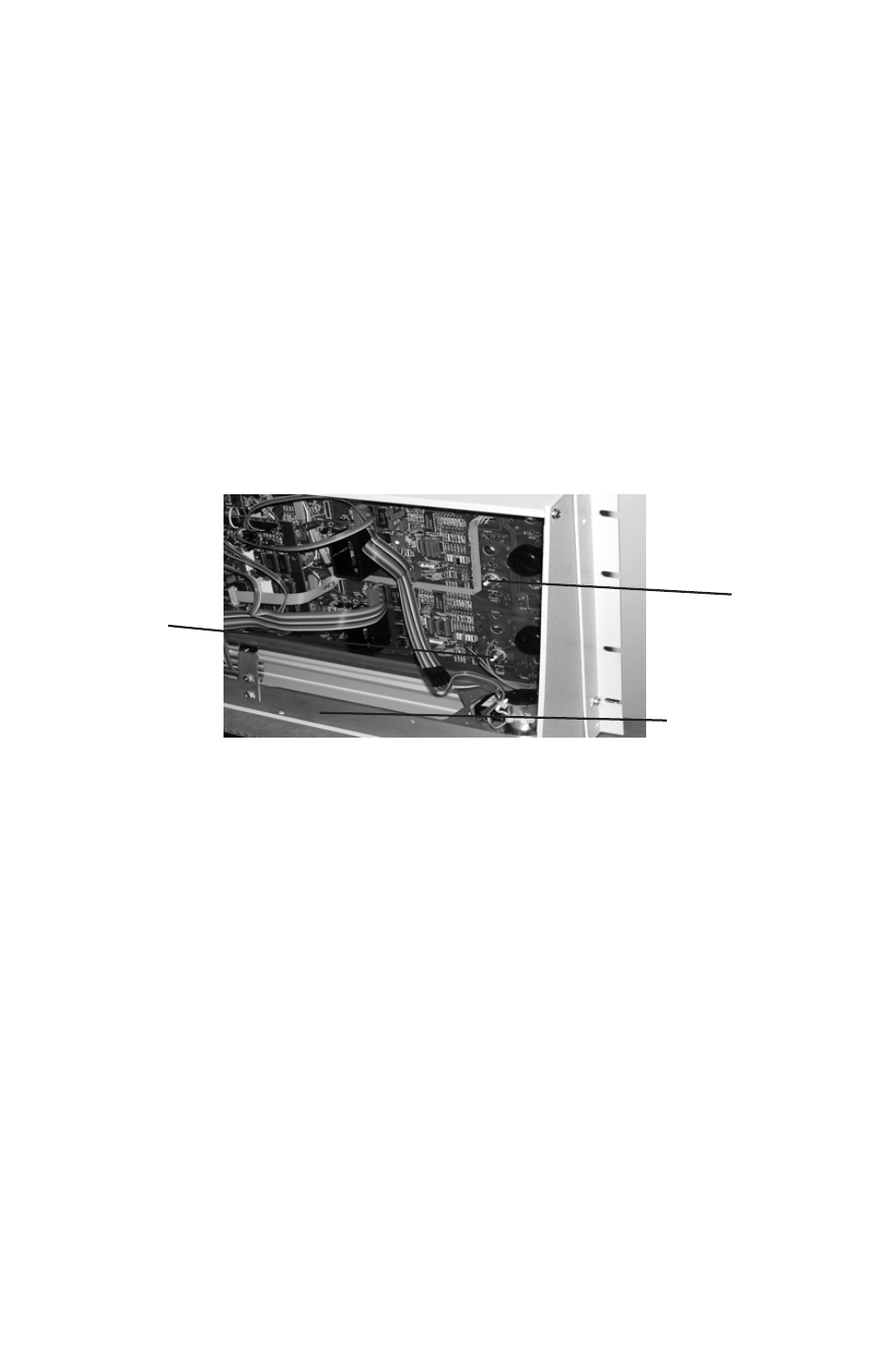

If an adjustment other than a zero shift is needed, remove the

recorder from the chassis leaving the cables connected and from

the picture below find potentiometer R231 (for the Y axis) . With

a small, plastic screw driver turn the pot to increase or decrease

the gain as required .

Calibration of the Flow or X axis is accomplished by measuring the platen

travel with a rule while keeping time with a stop watch (usually

1

/

2

" in 15

seconds is the measured distance and time check) while observing the chart

reading . If the travel is not within .50" +/- .04" on the chart adjust the gain

using pot R131 .

Maintenance

The machine and transducers should be kept clean and the machine should not be

over lubricated . Light oiling with synthetic instrument oil at most is required on

exposed spindles and threads; the jack and gear box are serviced with a premium

wheel bearing grease such as Pennzoil 707L Lubriplate Grease applied thru the

grease fitting no more than annually, or when an indication of power train friction

appears .

R231

R131

Top End

6