Caution, Maintenance caution – BE Pressure supply 5 Gallon Twin Tank Air Compressor AC205X User Manual

Page 19

19

maintenance

caution

Caution

Weekly

·· Check safety/relief valves by pulling rings. Replace safety/relief valves

that do not operate freely.

·· Inspect air filter element. Clean if necessary.

Monthly

·· Inspect for air leaks. Squirt soapy water around joints during compres-

sor operation and watch for bubbles. Tighten fittings if necessary.

·· Clean exterior.

3 months or 120 hours

·· Change petroleum lubricant in pump while crankcase is warm.

12 months or 1000 hours

·· Replace air filter element.

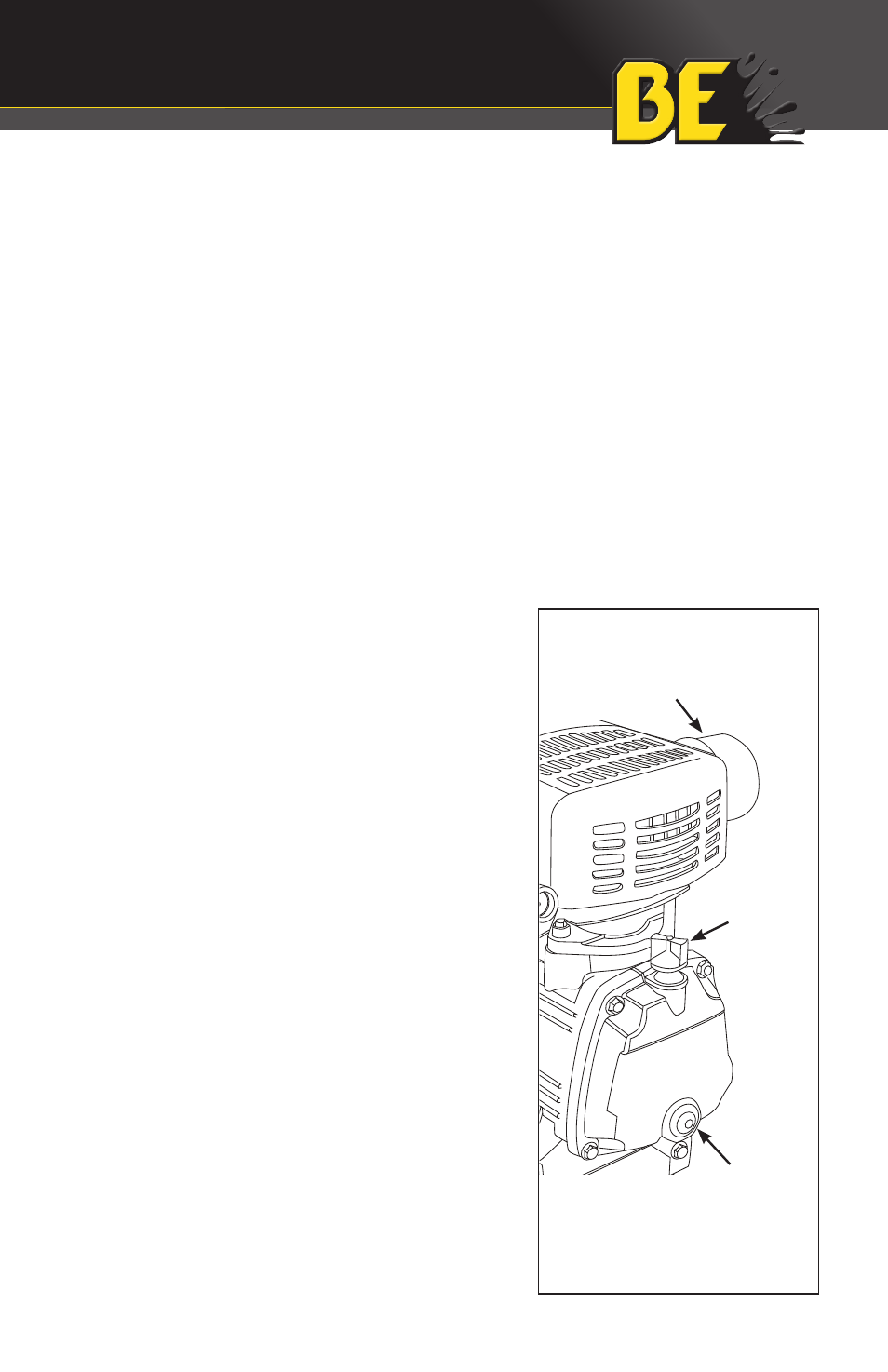

1. Put the cover off first and put the breath

pipe on the oil-hole and set the air filter

before the compressor run (Fig.4).

2. Never unscrew any connecting part when

the tank is in pressure condition.

3. Never disassemble any electrical part before

disconnecting the plug.

4. Never adjust the safety valve carelessly.

5. Never use the compressor in place where

voltage is too low or too high.

6. Never use electric wire more than 5m long

with less than the section of 1.5mm2, 16A.

7. Never disconnect the plug to stop com-

pressor, set the switch knob in position off

instead.

8. If the release valve doesn’t work as motor

stopped, find the cause immediately so as

not to damage motor.

9. Lubricating oil must be clean, oil level

should be kept in red circle of the oil leveler.

10. Before restarting the motor by pushing the

reset button, check the air

11. compressor carefully, find the causes of the

trouble and solve them, check the pressure

in the air tank and make sure it is under

0.8Mpa.

12. Disconnect the plug to cut off power supply

and open the outlet valve and discharge all

air in the air tank after use.

FIG. 4

OIL LENS

RESPIRATOR

AIR FILTER