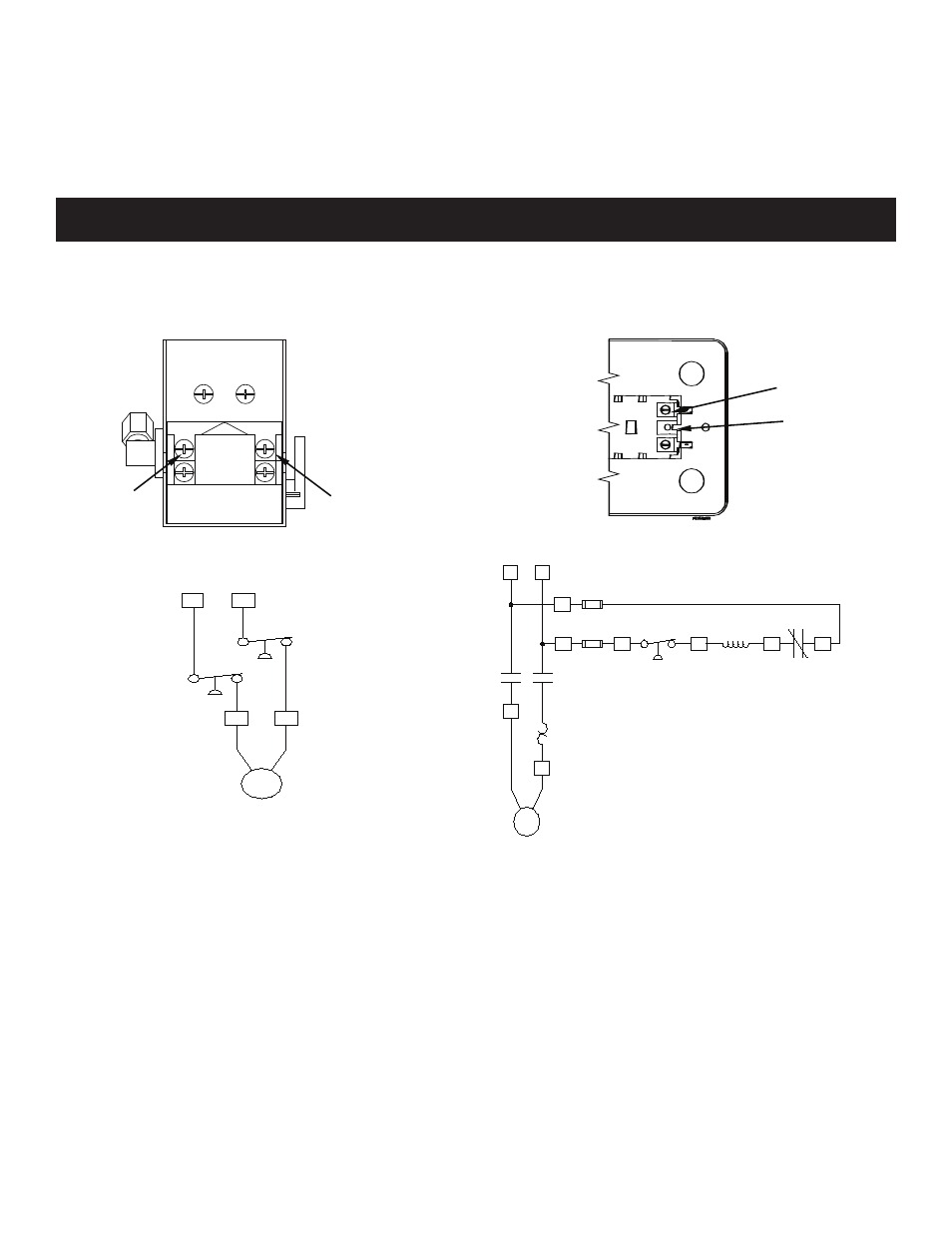

Wiring installation, Top view - pressure switch, Side view - motor starter – BE Pressure supply 80 Gallon Air Compressor AC5080B3 User Manual

Page 5: L2 l1

Condensation Discharge Piping. If installing a

condensation discharge line, the piping must be at least

one size larger than the connection, as short and direct

as possible, secured tightly and routed to a suitable drain

point. Condensation must be disposed of in accordance

with local, state, and federal laws and regulations.

WARNING! If an aftercooler, check valve, block valve,

or any other restriction is added to the compressor

discharge, install a properly sized ASME approved

safety/relief valve between the compressor discharge

and the restriction.

Wiring Installation

L2

L1

00857

L1

Electrical Service

Customer supplied wires

Pressure

Switch

M

Motor

B1

R1

L2

Pressure

Switch

00865

Motor

Starter

Overload

B1

M

L2

Motor

Starter

Contact

R1

L1

R2

Motor

Starter

Contact

B2

1A

FUSE

B3

R4

Motor

Starter

Coil

R5

Motor

Starter

Overload

R3

Electrical Service

Customer supplied wires

Motor

Pressure

Switch

00865

L2

L1

Model 459231

Top View - Pressure Switch

Model 459241

Side View - Motor Starter

General. The motor rating, as shown on the motor

nameplate, and the power supply must have compatible

voltage, phase and hertz characteristics.

Wire Size. The electrical wiring between the power

supply and electric motor varies according to motor

horsepower. Power leads must be adequately sized to

protect against excessive voltage drop during start-up.

Information for selecting proper wire size should be

provided by a qualified electrician. If other electrical

equipment is connected to the same circuit, the total

electrical load must be considered in selecting the

proper wire size. Do not use undersized wire.

NOTE: On units requiring a motor starter, connect line

power to the starter. DO NOT connect the line power to

the pressure switch.

Magnetic Starter. If the motor installed on your

compressor has a motor reset button, it does not

require a magnetic starter. If the motor does not have

this button, connect the power leads to the starter

located under the compressor top plate.

Circuit Breaker. Refer to the National Electric

Code to determine the proper circuit breaker rating

required. When selecting a circuit breaker, remember

the momentary starting current of an electric motor is

greater than its full load current. Time delay or “slow-

blow” circuit breakers are recommended.

WARNING! The installation should be made by

a qualified electrician. If the products must be

reconnected for use on different types of circuits, the

re-connection should be made by qualified personnel.