Installation – BE Pressure supply 80 Gallon Air Compressor AC5080B3 User Manual

Page 4

Installation

SELECTING A LOCATION

Select a well lit indoor area with plenty of space for proper

cooling air flow and accessibility. Locate the compressor at

least 15 inches (38 cm) from walls, and make sure the power

supply is clearly identified and accessible.

Temperature. Ideal operating temperatures are between 40º

and 100ºF (4º and 37ºC). If temperatures consistently drop

below 32ºF (0ºC), install the compressor inside a heated

building. If this is not possible, you must protect safety/relief

valves and drain valves from freezing.

CAUTION!

NEVER

operate in temperatures below 15ºF (-9ºC) or

above 125ºF (52ºC).

Humid Areas. In frequently humid areas, moisture may form

in the pump and produce sludge in the lubricant, causing

running parts to wear out prematurely. Excessive moisture is

especially likely to occur if the compressor is located in an

unheated area that is subject to large temperature changes.

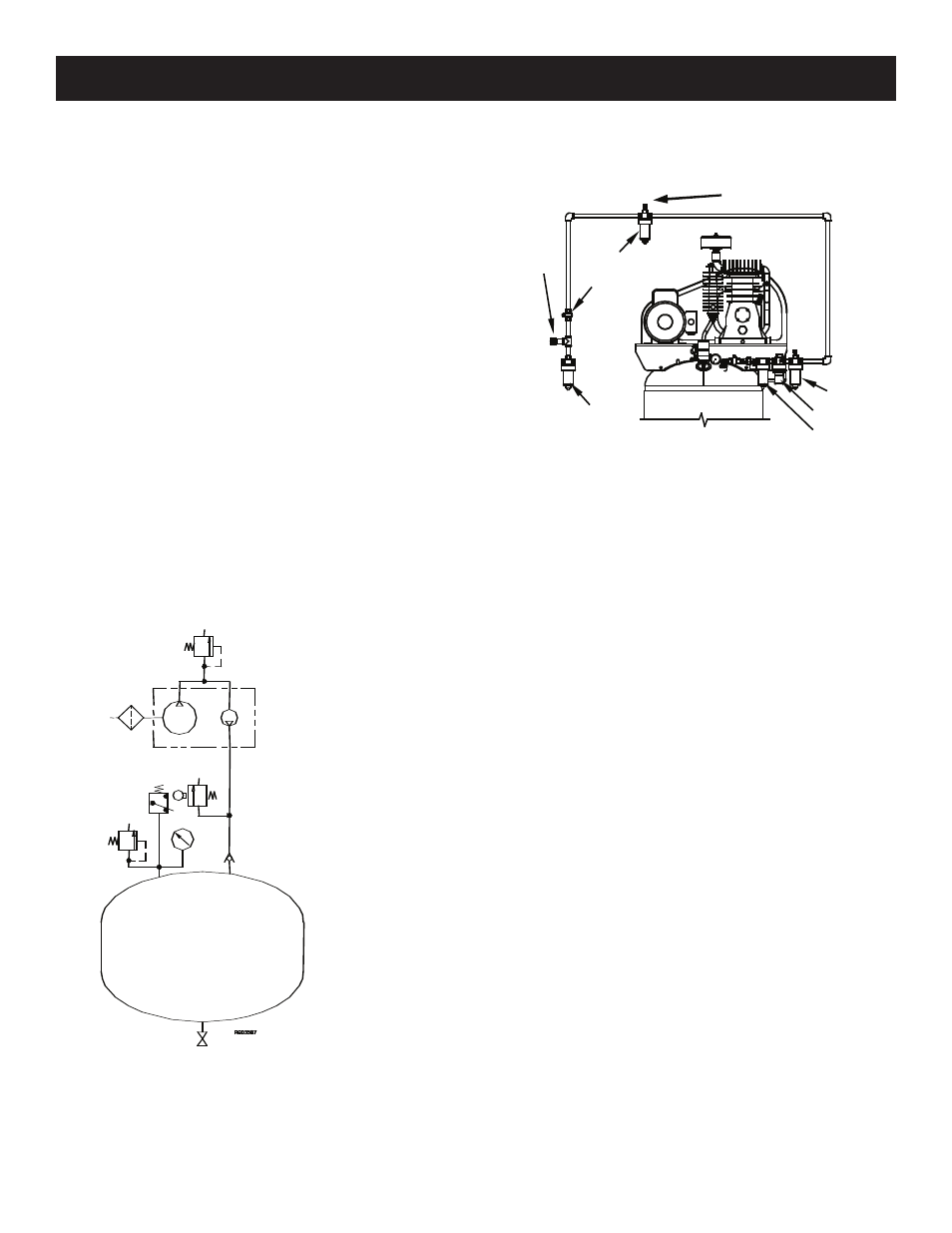

PNEUMATIC SCHEMATIC

80-Gallon Tank

Safety Relief

Valve

34796 Pump (Item #

459231

)

34798 Pump (Item #

459241

)

Unloader

Pressure

Switch

Safety

Relief

Valve

Note:

Pressure switch automatically activates the unloader.

SLOPE

TRAP

REGULATOR

FILTER/TRAP

LUBRICATOR

TRAP

OUTLET

VALVE

00855

INSTALLING DISCHARGE PIPING

CAUTION! If you will be using synthetic lubricant, all

downstream piping material and system components

must be compatible. Refer to suitable list on page 6.

General Requirements. The piping, fittings, etc. must

be certified for at least 4 times the working pressure. Use

hard-welded, threaded steel or copper pipes and cast

iron fittings that are certified safe for the compressors

discharge pressure and temperature. DO NOT USE PVC

PLASTIC. Use pipe thread sealant on all threads, and

make up joints tightly to prevent air leaks.

Main Air Distribution Line. The main compressed air

distribution line should be of sufficient size to minimize

the pressure drop between the air supply and the point

of use. Slope the piping downward in the direction of

air flow to aid in the removal of condensation at all drain

points along the line. The piping must be as short and

direct as possible, and adequately braced.

Drip Legs. A drip leg is a pipe extending downward

from the main line to collect condensation. Drip legs

should be at the lowest points in the air line and at any

point where the leg goes around an obstruction. A drain

valve should be installed at the bottom of each drip leg.

Drop Legs. A drop leg is piping originating from the

main air distribution line that feeds air to an outlet for

tools or other air operated devices. Drop legs are taken

off the top of the main line so that condensation does

not easily flow into them. Drop legs should be designed

so that the air outlet comes off the side of the drop leg,

rather than the bottom. By doing this, the condensation

which is carried from the main line collects below the

outlet and prevents moisture from entering the tool or

device using the air. A drain valve should be installed on

the bottom of each drop leg.