Rough in assembly – Amico British Standard Outlet User Manual

Page 12

12

Amico Pipeline

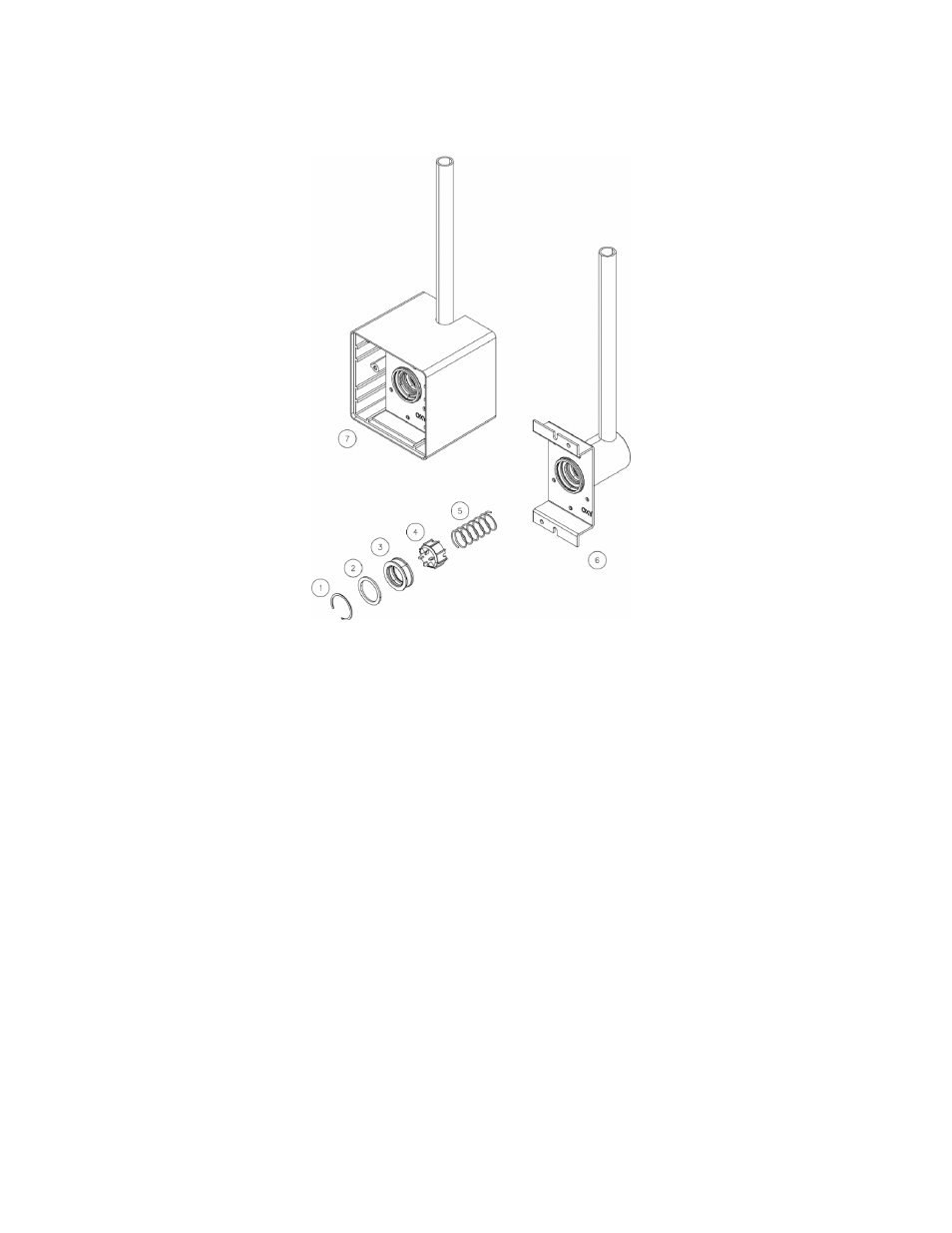

Rough In Assembly

CAUTION: Ensure that the supply pressure is shut off before performing service.

Inside the “Rough-in assembly” is a secondary check valve whose function is to shut off gas flow when the “Latch-valve

assembly “is removed. This seat/seal also prevents leakage around the latch valve connector. As the secondary seal is

only a static seal, it will rarely need replacement. However, if the seat/seal does need replacement, follow the following

procedure:

NOTE:

Suction inlets (Vacuum and AGSS) are not supplied with Secondary Check Valves. The Secondary Check Valve (4)

and Secondary Check Valve Spring (5) are not required.

1. Ensure that no pressure exists in the line by depressing the secondary check (4).

2. Remove the retaining ring (1) from the inside of the outlet body. Use a small screwdriver to pull the end of the ring

toward the center and then pull the ring up and out.

3. Remove the washer (2), seat/seal (3), secondary check valve (4) and the secondary check valve spring (5). Inspect

items for wear or damage and replace the seat/seal (3).

4. Re-install the spring (5), secondary check valve (4), seat/seal (3) and the washer (2). Insert the retaining ring (1) into

the slot and ensure that the whole ring is seated properly.

5. Turn on the pressure and check for leaks. Re-install the “Latch Valve assembly” and perform then inspection and

test.