Troubleshooting preventative maintenance – Amico Equipment Rails User Manual

Page 9

www.amico.com

8

Troubleshooting

Preventative Maintenance

WARNING:

All products require periodic inspection and maintenance to perform optimally and achieve

maximum operation life.

WARNING:

The intervals shown below are recommended. Maintenance schedules should be more frequent

for products that see heavy use.

NOTE:

Please contact Amico Accessories for MRS Cover orders.

Section 5: Maintenance, Troubleshooting

and Product Classification

Symptom

Possible Cause

Solution

The depressible channel stop is loose.

The screw securing the channel is loose.

Tighten screw, if problem persists please

contact Amico Accessories Inc.

The rubber stop is loose.

The mounting screw securing the rubber

stop is loose.

Tighten screw, if problem persists please

contact Amico Accessories Inc.

The rail is loose/unstable.

The mounting screws have loosened.

Contact Structural Engineer to

discuss solution.

Area

Maintenance

Period (Months)

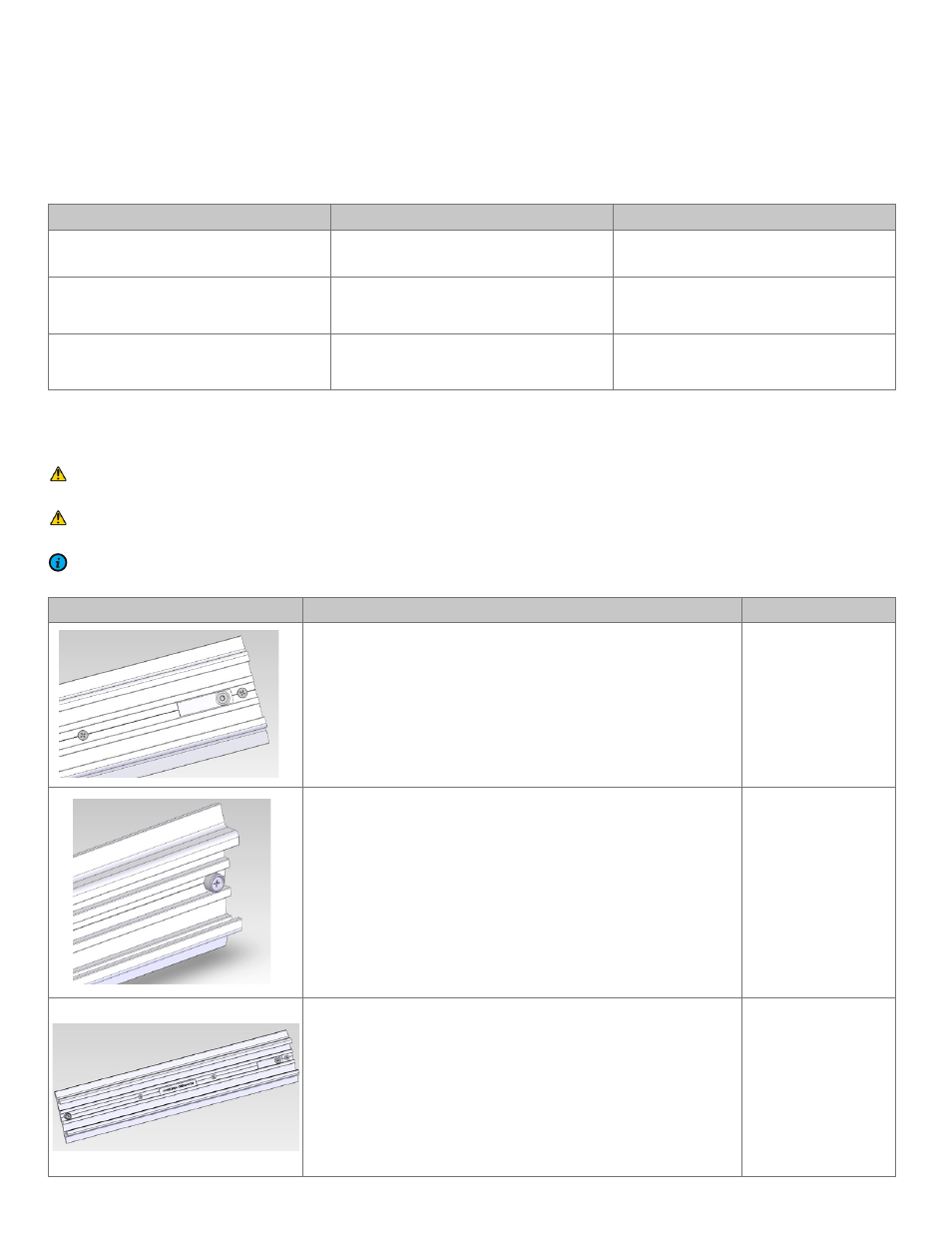

Area 1: Depressible channel stop on MRS rail.

A) Visually inspect for any loosening of the mounting screw for

the depressible channel stop.

B) Check the screw every six months.

6

Area 2: Rubber stop at the bottom of MRS rail.

A) Visually inspect for any loosening of the mounting screw for

the rubber stop.

B) Check the screw every six months.

6

Area 3: Entire MRS rail.

A) Visually inspect for any loosening of any mounting screws

on any MRS.

B) Check rail screws every six months.

6