Spring length, Opener depth, Press wheel adjustment opener mounting – Great Plains 1005NT Operator Manual User Manual

Page 15

13

Section 3 Adjustments

4/12/05

705 and 1005 End-Wheel No-Till Drill 150-213M

Great Plains Mfg., Inc.

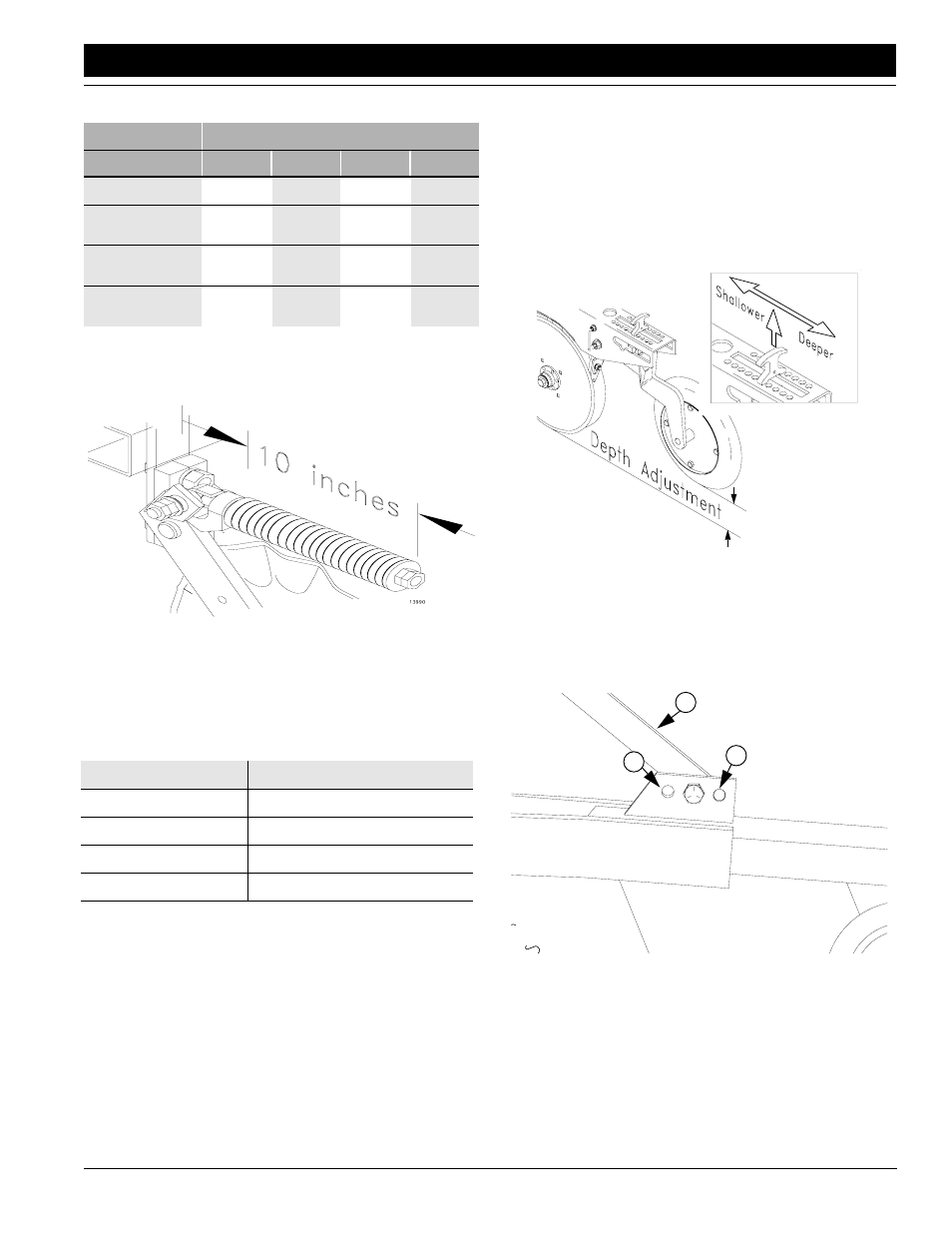

Spring Length

Coulter springs are preset at 10 inches, giving coulters an

initial operating force of 400 pounds. This setting is ade-

quate for many difficult no-till conditions.

Figure 3-2

Coulter Spring Length

For lighter no-till conditions where rocks or other obstruc-

tions are a problem, you can lengthen coulter springs to

protect coulters from impact. Refer to the chart below for

spring length and corresponding coulter down force.

NOTE: Resetting coulter-spring length shorter than 9 3/4

inches may contribute to premature failure of parts and

warranty will be voided. If additional force is needed, add

weights to drill.

Opener Depth

Press Wheel Adjustment

Set opener seeding depth by adjusting press-wheel

height. To adjust, first raise drill slightly, then lift and slide T-

handles on top of openers as shown in Figure 3-3. Adjust

all press wheels to same height.

•

For shallower seeding, slide T-handles toward drill.

•

For deeper seeding, slide T-handles away from drill.

Figure 3-3

Press Wheel Depth Adjustment

Opener Mounting

You may need to lower openers that run in tire tracks. To

lower individual openers, connect opener spring bar (1) in

a higher hole (2). Move spring bar to a lower hole (3) to

raise opener.

Figure 3-4

Spring Bar Adjustment

1005

Pounds per Coulter

7 inch

7.5 inch

8 inch

10 inch

Empty Drill

266

275

285

326

Drill with Weight

Brackets

287

297

309

356

Drill with 800

pounds added

337

351

366

429

Drill with 1000

pounds added

350

364

380

447

13990

15659

17450

1

2

3

Spring Length

Initial Vertical Coulter Force

10 1/2 Inches

175 pounds

10 1/4 Inches

300 pounds

10 Inches

400 pounds

9 3/4 Inches

525 pounds