Section 2 operating instructions, Prestart checklist field operation, Opener operation native grass operation – Great Plains 1005NT Operator Manual User Manual

Page 11: Prestart checklist, Field operation

9

Section 2 Operating Instructions

4/12/05

705 and 1005 End-Wheel No-Till Drill 150-213M

Great Plains Mfg., Inc.

Section 2

Operating Instructions

This section covers general operating procedures. Experi-

ence, machine familiarity and the following information will

lead to efficient operation and good working habits.

Always operate farm machinery with safety in mind.

Prestart Checklist

1.

Carefully read “Important Safety Information,”

beginning on page 1.

2.

Lubricate the drill as indicated under Lubrication,

“Maintenance and Lubrication,” page 29.

3.

Check that drill tires are 9.00 x 24 and are properly

inflated as indicated on Tire Inflation Chart, “Appen-

dix,” page 35.

4.

Check all bolts, pins and fasteners. Torque as speci-

fied on Torque Values Chart, “Appendix,” page 35.

5.

Check the drill for worn or damaged parts. Repair or

replace them before going to the field.

6.

Check hydraulic hoses, fittings and cylinders for leaks.

Repair or replace before going to the field.

Field Operation

1.

Hitch drill securely to a tractor with sufficient weight

and horsepower. Refer to Tractor Requirements,

“Specifications and Capacities,” page 34 and Hitch-

ing Tractor to Drill, “Preparation and Setup,” page 7.

Make sure drill safety chain is secured to tractor.

2.

Perform all checks listed on Prestart Checklist, this

page.

3.

Extend lift cylinders completely and remove lock pins

from transport position. Place pins in storage. See

Figure 2-1.

Figure 2-1

Lock Pin, Storage Position

4.

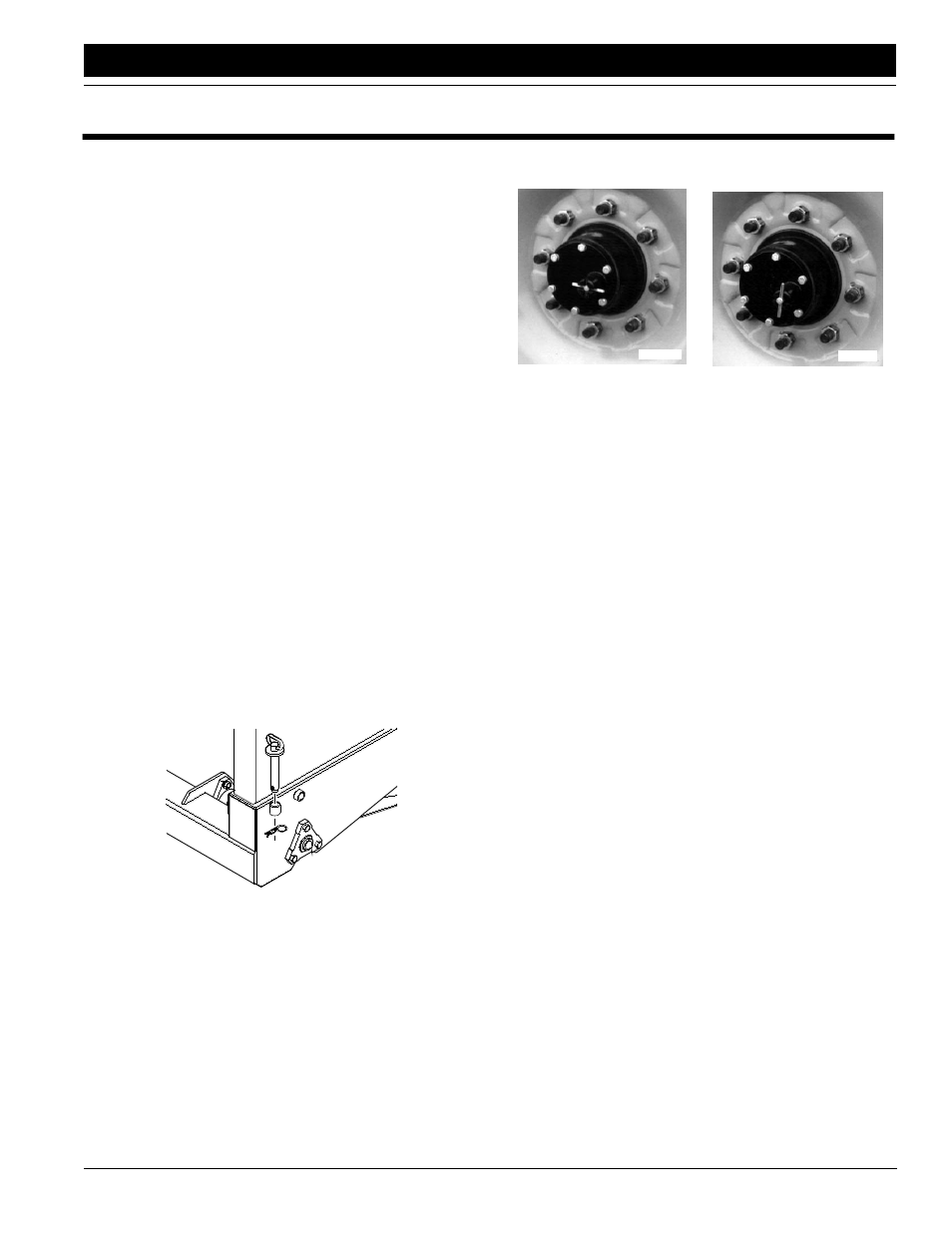

Engage drive by turning lock-out hub. See Figure 2-2.

The lock-out hub is on the left end wheel.

Figure 2-2

Lock-Out Hub

5.

Calibrate seeding rate as explained under Seed Rate

Adjustment, “Adjustments,” page 14.

6.

Load seed box with seed. Use cleaned seed for best

results.

7.

Record reading on acremeter, which is mounted on

right-hand end of jackshaft. Subtract this initial read-

ing from later readings to calculate acres drilled.

8.

Lower drill and begin seeding.

9.

Always raise drill for field turns. Seeding will stop auto-

matically as you raise drill.

Opener Operation

Never back up with openers in ground. If you do, check all

openers to be sure none are clogged. Always lift drill out of

ground when turning at ends of field rows and other short-

radius turns.

For information on seeding depth and opener adjust-

ments, refer to Seeding Depth and Opener Depth,

“Adjustments,” beginning on page 12.

Native Grass Operation

Native grass drills have a partition dividing the seed and

native-grass compartments. Seed-compartment capacity

is 1.3 bushels per foot, and native-grass capacity is 1.2

bushels per foot.

If native grass is not being used, remove chain from

native-grass-drive sprocket to eliminate wear on drive sys-

tem.

10252

Engaged

Disengaged

17459

17458