Small seeds rate, Small seeds rate calibration, Small seeds rate small seeds rate calibration – Great Plains 3S-4010HDF Material Rate User Manual

Page 23

Great Plains Mfg., Inc.

21

01/29/2009

196-522B

Small Seeds Rate

Seeding rate from the optional Small Seeds Attachment

is controlled entirely by seed rate handles on each small

seeds box. No sprocket changes are required, and small

seeds rate is unaffected by settings for main seed box.

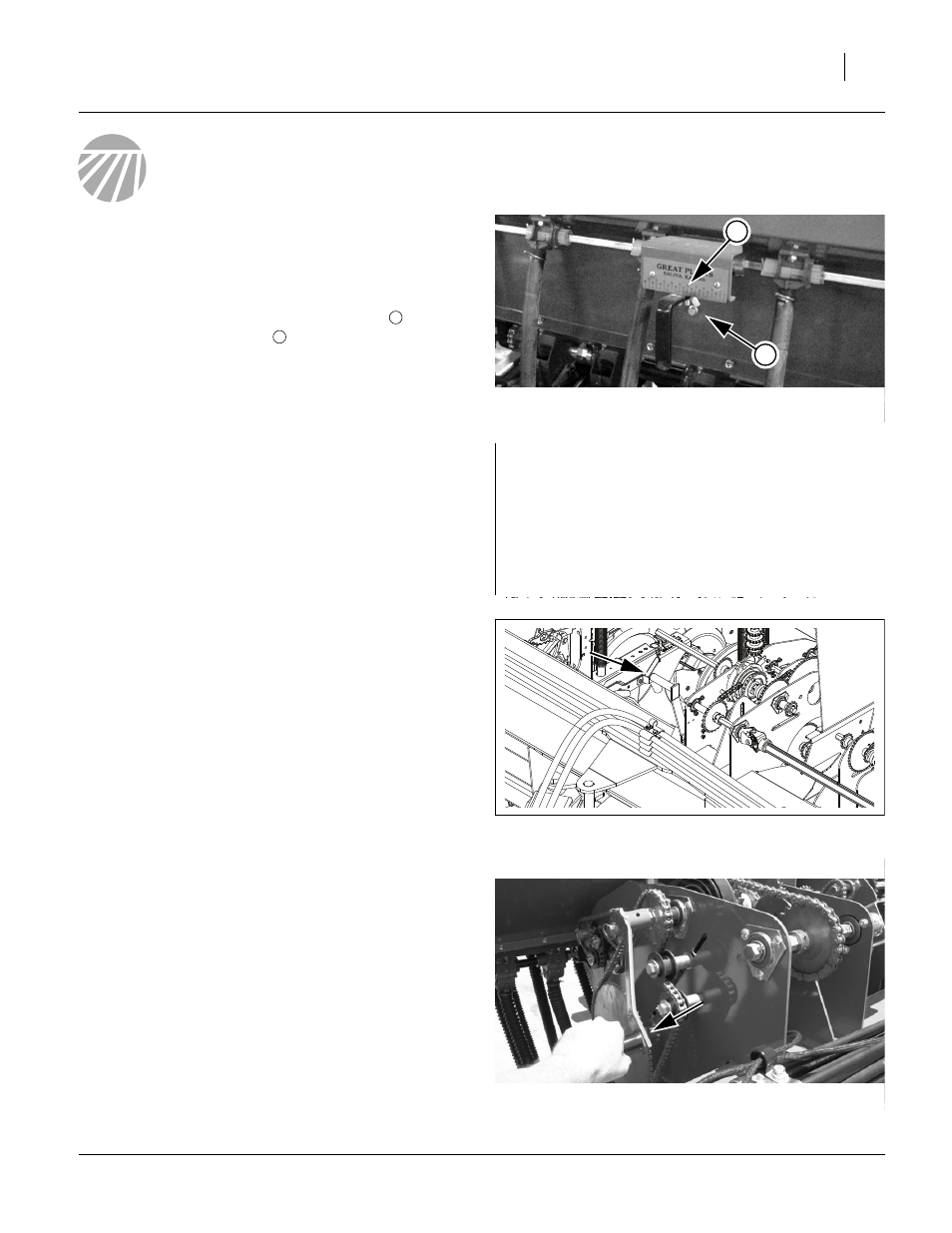

To set Small Seeds rate, loosen the wing nut

handle, and adjust the lever

Small Seeds Rate Calibration

Differences will exist between the tested seed and field

conditions used to generate the Small Seeds Rate

Charts, and your seed and conditions. To accurately

achieve your target population, Great Plains recom-

mends calibrating.

As small seed rates are typically far lower than main box

seed rates, use a scale that is accurate for small weight

differences, or sample more than the usual three rows.

1.

Lower drill. Set MASTER switch on clutch control

box to OFF position.

2.

Set the small seed rate handle based on the seed

and rate desired.

3.

Remove the calibration crank from its storage loca-

tion on the right section drive. Remove pin from

crank and return to storage stob.

4.

On the right drill section, if fertilizer rate is not also

being calibrated at the same time, and fertilizer is

present, remove a fertilizer box drive chain on the

right drill section.

5.

Install crank on clutch shaft of right section.

Crank rotation is clockwise, facing to drill left.

6.

Use crank to turn clutch shaft and check that the

drives and seed cups are engaged, working properly

and free from foreign material. If not already done,

set the Small Seeds Rate Handle.

Figure 11

Small Seeds Rate Handle

18511

For example: using a row spacing of:

7.5in

and a row count of:

64

you desire to plant alfalfa at:

8 lbs/ac;

this corresponds to an initial Seed Rate Handle of:

40

1

2

2

Figure 12

Stored Calibration Crank

29240

Figure 13

Installed Calibration Crank

28180