Great Plains 1205-NT Assembly Instructions User Manual

Page 6

6

1205-NT Folding Marker Option 113-549M

5/5/09

Great Plains Mfg., Inc.

Single or Dual Markers

Without a Sequence Valve

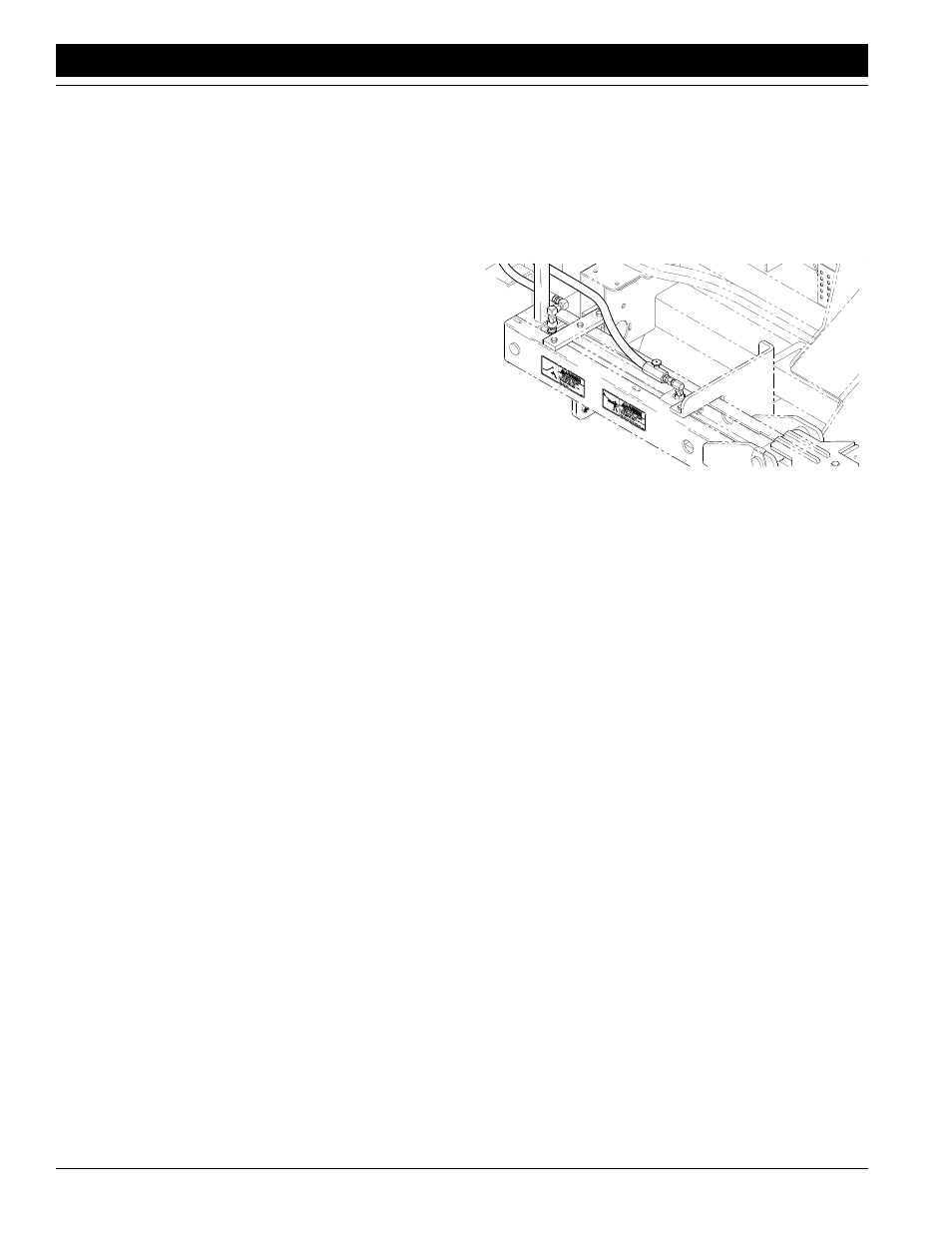

Refer to Figure 5:

1.

The markers should be manually folded into the transport

position when charging the hydraulic system for the first

time. Disconnect the cylinder pin (#1) from the rod end of the

cylinders and the marker link arms (#2) and swing the link

arm up and out of the way.

2.

Connect the hoses to the tractors remote hydraulic outlets.

3.

Loosen the hose hydraulic fittings at the rod end of the mark-

er cylinders (#3). With the tractor at idle speed, slowly work

the tractor remote lever in the direction which would retract

the cylinder. Don't try to retract the cylinder, the goal is to

push the air from the lines leading to the cylinder. When the

air is expelled and oil starts being pushed out, tighten the

hose connection at this cylinder.

4.

Slowly work the tractor's remote lever in the same direction

to retract the cylinder. When it is retracted, loosen the hose

fitting at the base end of the same cylinder (#4). With the

tractor at idle speed, slowly work the tractor remote lever in

the opposite direction which should put oil to the cylinder

base port. When the air is expelled and oil starts being

pushed out, tighten the hose connection at this cylinder.

5.

Once again, slowly work the tractor's remote lever in the di-

rection to fully extend the cylinder and hold it there for a few

seconds.

6.

If you have dual markers, repeat steps 3 through 5 for the

other cylinder.

7.

Once the system is bled, operate the tractor's remote levers

to fully extend the marker cylinders and reconnect the cylin-

ders to the marker link arms.

8.

The marker hydraulic system is equipped with needle valves

to control how fast each marker operates. The needle valves

are located in the hydraulic hose lines at the rod end of the

marker cylinders. Turn the adjustment heads clockwise to

slow the speed down and counterclockwise to speed it up.

Adjustments should be made for safe speeds at operating

rpm. Excessive folding speeds can cause marker damage

and may void the warranty, refer to

Needle Valve At Marker

Figure 7

14062