Position seed-cup doors check seeding rate, Seed rate charts – Great Plains 2515 Operator Manual User Manual

Page 20

18

Section 3 Adjustments

1515, 2015 and 2515 Three-Point Soybean Machine 173-159M

4/20/05

Great Plains Mfg., Inc.

Seed Rate Charts

Seed-Rate-Handle Set-

ting

0

5

10

15

20

25

30

35

40

45

50

55

60

65

70

75

80

85

90

95

100

Cotton

Delinted

Drive Type 1

0.0

0.8

1.7

2.8

4.0

5.4

6.9

8.4

10.1

11.8

13.5

15.2

16.9

18.6

20.2

21.7

23.1

24.5

25.6

26.6

27.5

Drive Type 2

0.0

1.7

3.5

5.7

8.3

11.1

14.1

17.3

20.7

24.2

27.7

31.2

34.7

38.2

41.5

44.6

47.6

50.3

52.7

54.8

56.5

Barley

(51 lb/bu)

Drive Type 1

0.7

1.7

2.9

4.1

5.6

7.0

8.6

10.1

11.7

13.4

15.1

16.8

18.5

20.5

22.1

23.9

25.4

26.8

28.1

28.3

28.6

Drive Type 2

1.4

3.4

6.2

8.5

11.7

14.5

17.8

21.1

24.3

28.0

31.3

34.2

37.7

41.0

44.7

48.3

52.3

56.1

59.7

60.6

61.6

Milo

Drive Type 1

0.0

1.8

3.4

5.0

6.9

8.7

10.8

13.0

15.1

17.4

19.9

22.0

24.3

26.7

28.9

31.3

33.5

35.5

37.8

38.8

39.5

Peas

(61 lb/bu)

Drive Type 3

0.0

3.8

7.5

13.4

20.4

27.0

33.0

40.1

46.8

54.1

60.7

66.7

73.3

79.3

85.9

92.7

98.8 104.8 110.8 111.4 111.9

Drive Type 4

0.0

0.0

8.5

18.2

28.1

38.2

47.4

58.4

68.7

79.1

88.6

98.7 108.0 118.2 127.8 137.5 147.3 156.6 165.4 165.7 165.9

Pinto

Beans

Drive Type 1

0.0

0.0

3.3

5.0

6.7

9.1

11.4

13.7

16.0

18.2

20.5

22.6

24.7

26.7

28.8

31.3

33.1

35.1

37.3

37.4

37.4

Drive Type 2

0.0

0.0

6.9

10.5

14.3

18.2

23.1

26.7

31.6

36.3

41.2

45.5

50.1

54.6

58.7

63.0

67.6

72.0

76.0

76.4

76.7

(61 lb/bu)

Sudan

Drive Type 1

0.0

1.5

3.2

4.5

6.2

7.8

9.4

11.0

12.7

14.3

16.2

17.7

19.3

21.1

22.9

25.0

27.0

29.3

31.7

32.2

32.9

(55 lb/bu)

Soybeans

(58 lb/bu)

Drive Type 2

0.0

2.3

6.3

10.6

15.6

18.7

23.2

27.3

31.7

36.1

40.0

44.9

49.3

53.6

57.8

62.3

65.9

70.3

74.9

75.2

75.5

Drive Type 3

0.0

4.5

8.9

15.9

23.4

27.8

35.0

39.8

45.8

51.7

58.3

64.6

71.1

77.3

84.1

89.6

97.7 104.4 111.7 111.8 111.9

Drive Type 4

0.0

7.3

14.2

25.5

37.5

44.5

56.0

63.6

73.3

82.7

93.3

103

114

124

135

143

156

167

179

179

179

Sunflowers

Drive Type 1

0.0

0.0

0.8

1.6

2.4

3.2

4.1

5.0

5.9

6.9

7.8

8.7

9.6

10.6

11.5

12.4

13.2

14.0

14.8

15.3

15.8

(28 lb/bu)

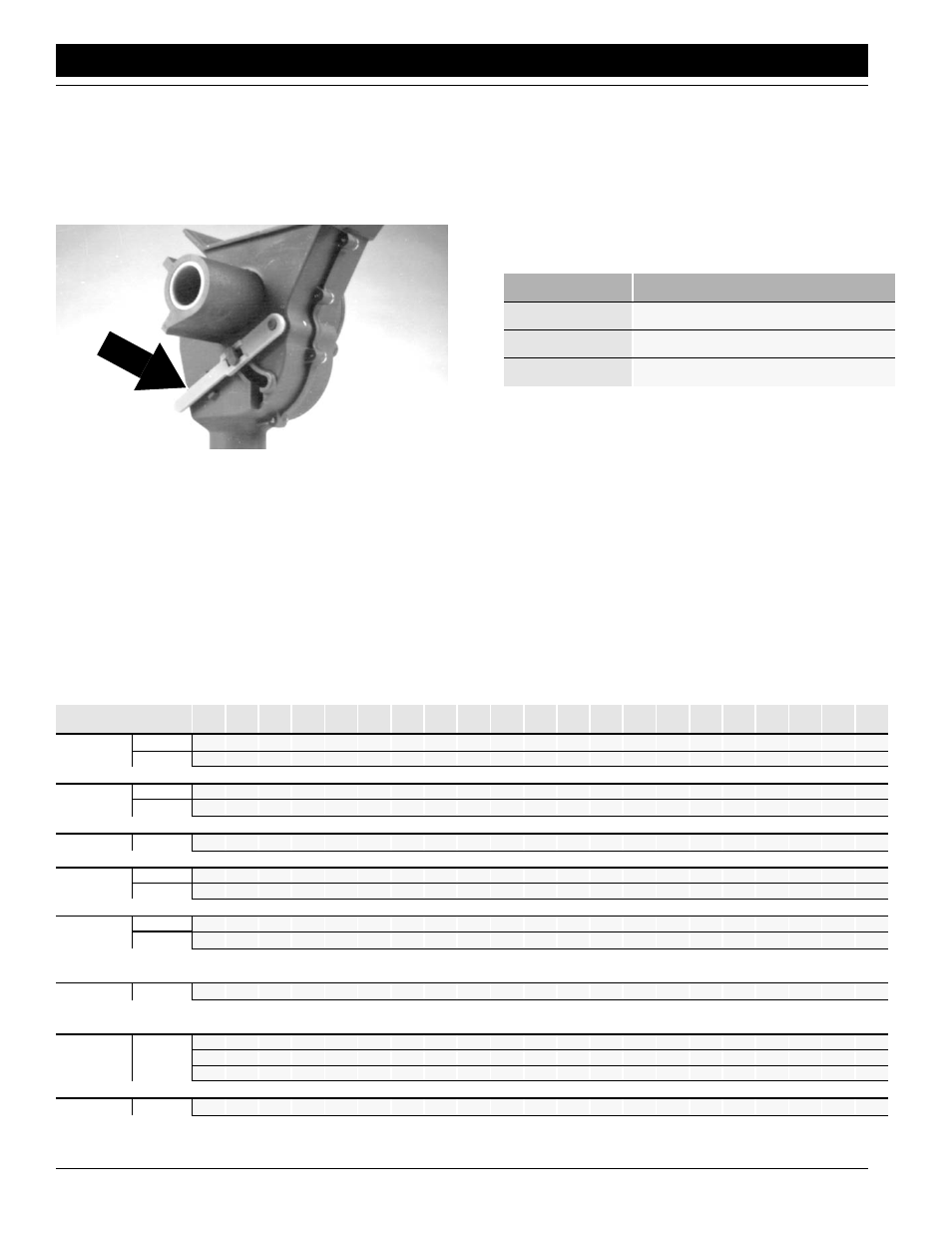

Position Seed-Cup Doors

For wheat and other small seeds, move seed-cup-door

handles to highest position. For soybeans and other large

seeds, lower handles to second position. If excessive seed

cracking occurs, lower handles to third position. For seed-

cup clean out, move handles to fourth, wide-open position.

Make sure all handles are in same position before drilling.

Figure 3-14

Seed-Cup-Door Handle

Check Seeding Rate

1.

Record the weight of an empty container large enough

to hold seed metered for one acre.

2.

Place several pounds of seed over three seed cups on

an outside end of drill box. Pull seed tubes off these

three openers.

3.

Raise drill off ground.

16491

4.

Turn gauge wheel a few turns to fill cups with

seed. Turn wheel until seed drops to ground from

all three cups.

5.

Place a container under the three seed tubes to

gather seed as it is metered.

6.

Turn drive gauge wheel for one acre. Refer to the

chart below for the exact number of tire revolu-

tions to equal one acre. Check that three seed

cups have plenty of seed coming into them.

7.

Weigh metered seed. Subtract initial weight of

empty container. Divide by three for the amount

metered by each seed cup, then multiply by the

number of drill openers for the pounds-per-acre

seeding rate. If this figure is different than desired,

adjust the seed-rate handle and recheck the rate.

NOTE: If your results vary greatly from the charts, you

may want to repeat the calibration procedure.

8.

When drilling, note acres drilled, amount of seed

added and level of seed in drill box. If you are

seeding more or less than desired, adjust seeding

rate slightly to compensate for your field condi-

tions.

Drill

Tire Revolutions for One Acre

1515

364

2015

283

2515

223