Troubleshooting – Great Plains CPH-20 Operator Manual User Manual

Page 19

17

Section 4 Troubleshooting

12/29/2011

CPH Center Pivot Hitch 148-152M

Great Plains Mfg., Inc.

Section 4

Troubleshooting

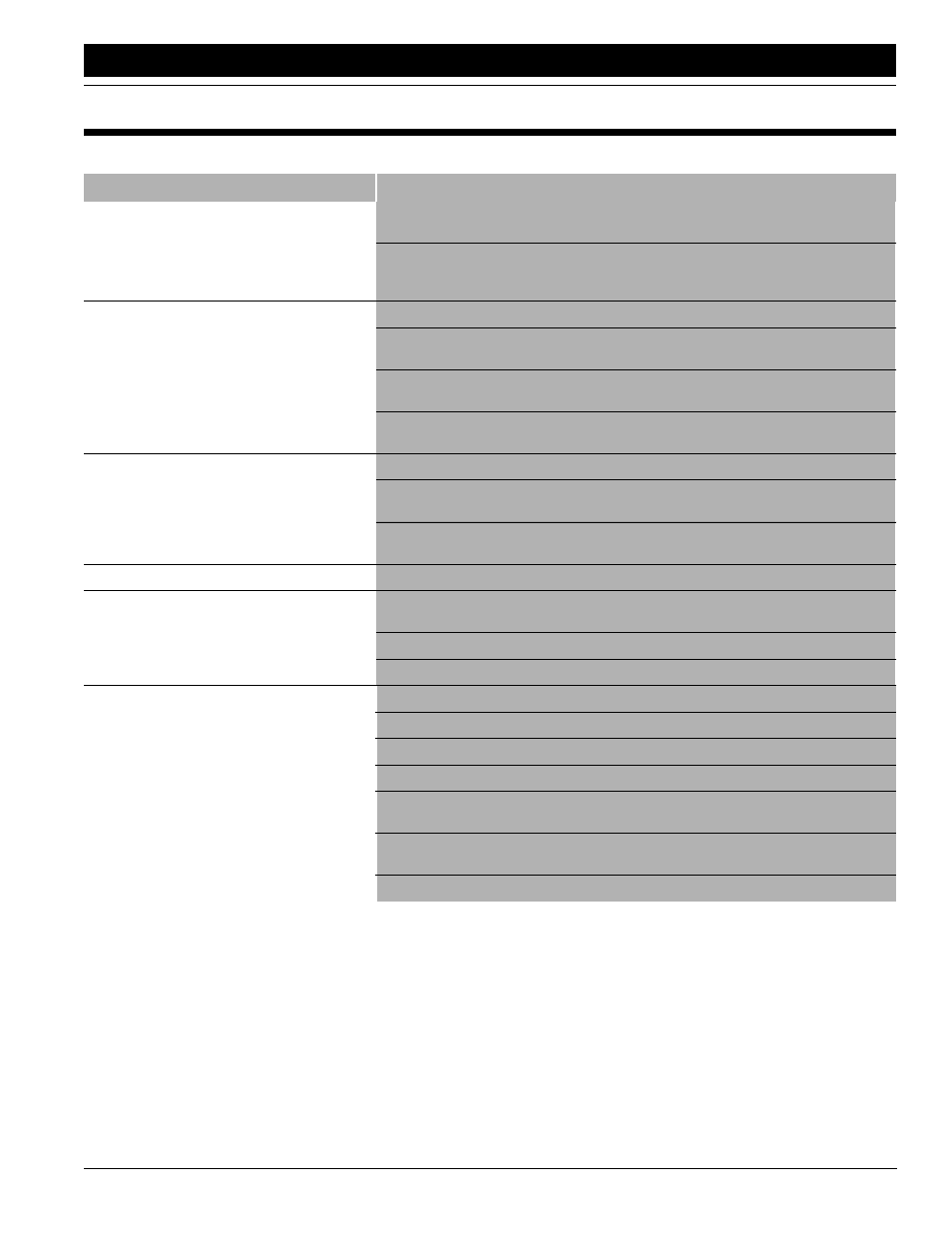

Problem

Solution

Drill raising and lowering rough and uneven

Check for too little play in slide-block area. Refer to Maintenance, “Mainte-

nance and Lubrication,” page 18.

Check for air trapped in hydraulic lines or cylinders. Bleed hydraulics if nec-

essary. Refer to Bleeding the Hydraulic Systems, “Preparation and Setup,”

page 9.

Coulters not going deep enough

Retract tongue cylinder.

Add weight to hitch frame. Refer to Coulter Down Pressure, “Adjustments,”

page 13.

Too much weight is being used by openers; set drill openers to lightest

spring setting. Refer to drill operator’s manual.

Shorten coulter springs to increase down pressure. Refer to Coulter Down

Pressure, “Adjustments,” page 13.

Drill not tracking behind coulters

Check if coulters are aligned with openers.

Check that pivot-lock tubes are in drilling position. Refer to Figure 2-2

,

page

11

.

Check if leaf spring is out of alignment. Refer to Leaf Spring Adjustment,

“Adjustments,” page 15.

Openers plugging in no-till conditions

Drill across standing residue.

Drill planting too deep

Link is letting drill tip back too much. Refer to Level Drill with Hitch, “Prepa-

ration and Setup,” page 9.

Change the press-wheel setting. Refer to drill operator’s manual.

Remove weight from hitch.

Uneven seed spacing or uneven stand

Check for plugging in drill seed cups.

Check if drill seed tubes are plugged.

Reduce ground speed.

Check that drill opener disks turn freely.

Use a faster drive type and a lower seed-rate-handle setting. Refer to drill

operator’s manual.

Increase opener down pressure so opener disks penetrate. Refer to drill

operator’s manual.

Check for trash or mud build-up on optional Seed-Lok

® wheels.