4 disc units, 5 dd lite roller, 6 dd600 roller – Great Plains P18028E Operator Manual User Manual

Page 21

21

DTX

Operating Instructions

Fig. 4.05: DD Lite Roller

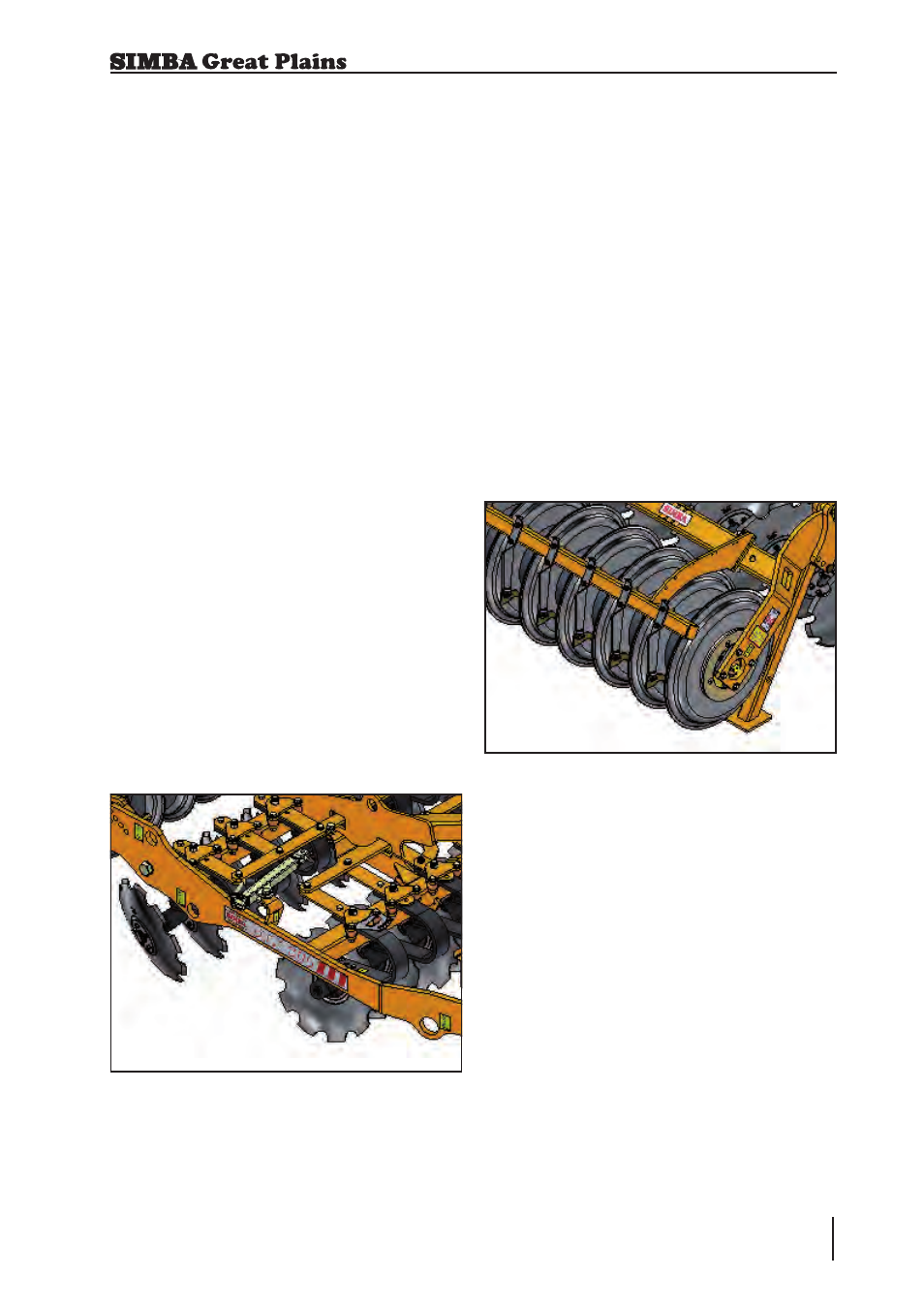

4.4 Disc Units

The DTX features two rows of discs which

chop and mix the crop residue. A disc

spacing of 250mm ensures a fine tilth.

The discs fitted to the DTX are 500mm in

diameter (20”) and 6mm thick. They are

manufactured from heat treated chrome

boron steel which ensures excellent wear

resistance and enhanced working life.

Each disc is mounted on a Pro-Active

sprung leaf linked to a track rod system.

Gang angles can be varied with ease and

accuracy using a graduated adjuster.

Adjustable angling of the discs (between

10°-25°) ensures penetration and stubble

mixing are achieved in one pass. Working

depth can be varied via the 3 point linkage

and the rear roll linkage.

A level, evenly cultivated finish is maintained

by adjusting the balance of soil throw

between the front and rear disc.

Sprung Pro-Active leaves offer protection

against damage as well as offering a

degree of contour following as they flex up

and down in work.

Fig. 4.04: Discs

4. Adjustment / Operation

4.5 DD Lite Roller

The DD Lite roller is made up of individual

Double Disc (patented) Ring segments.

The DD Lite roll is designed to consolidate

the soil whilst cutting and crushing any

clods.

Even in heavy, wet soils it can easily be

operated with minimal blockages occurring.

The rear DD Lite roller carries a proportion

of the machine’s weight to ensure

consolidation. It also regulates the depth

of the disc units. The corrugated surface

left by the roller is weatherproof both for

wet or dry situations.

4.6 DD600 Roller

The standard DD600 roller is made up of

individual Double Disc (patented) Ring

segments.

The DD rings are designed to consolidate

the soil whilst cutting and crushing any clods.

Even in heavy, wet soils it can easily be

operated with minimal blockages occurring.

The rear DD Lite roller carries a proportion

of the machine’s weight to ensure

consolidation. It also regulates the depth

of the disc units. The corrugated surface

left by the roller is weatherproof both for

wet or dry situations.