Marker adjustments, Marker disk angle, Marker speed – Great Plains 3PNG15 Operator Manual User Manual

Page 27: Folding speed with needle valves, Marker disk angle marker speed, Warning, Caution

Great Plains Manufacturing, Inc.

Adjustments

23

10/06/2008

202-553M

Marker Adjustments

See other sections for these marker items:

Marker Setup:

“Marker Extension Setup” on page 45

Marker Maintenance:

“Charge Hydraulic System” on page 45

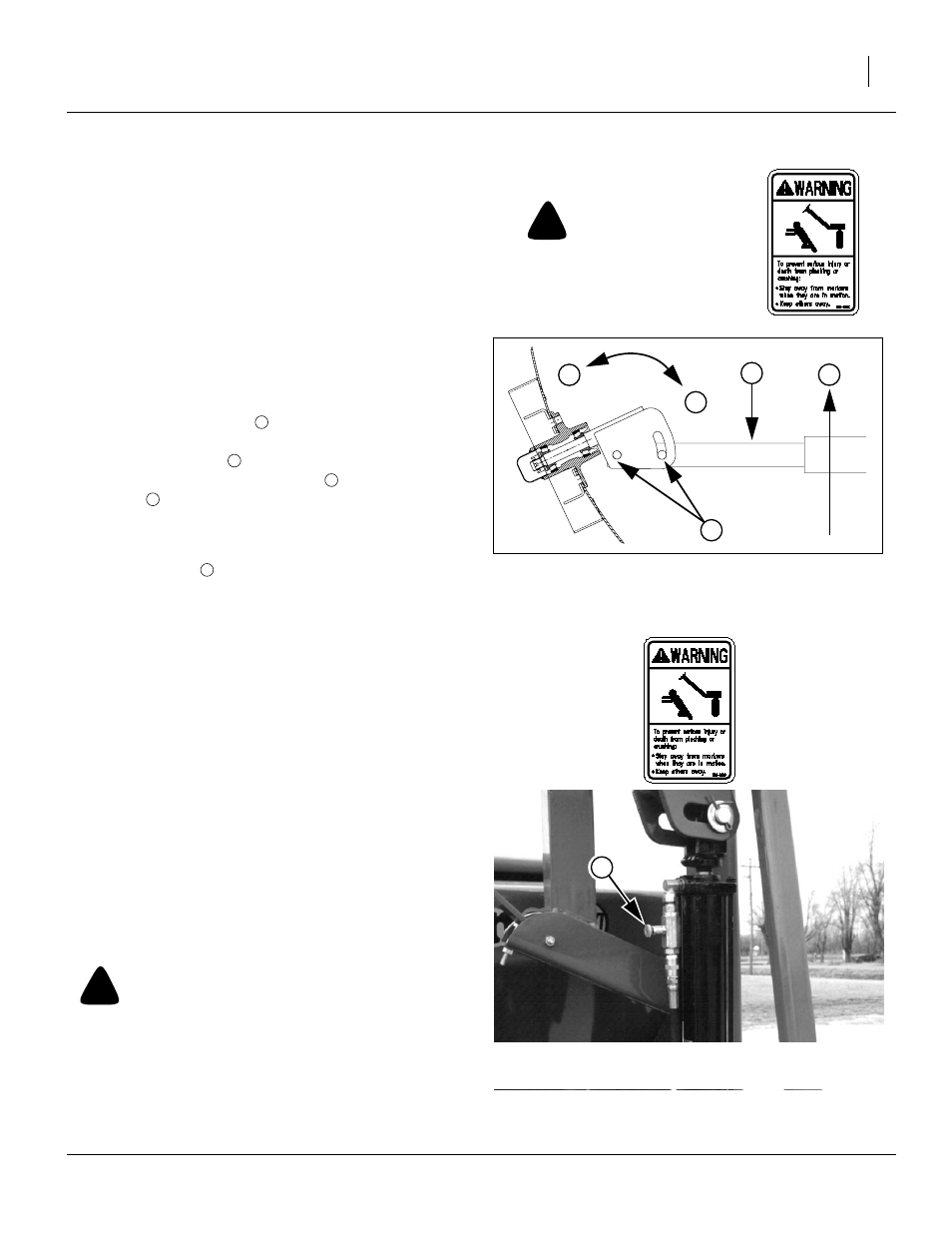

Marker Disk Angle

Refer to Figure 12

To change angle of cut, and the width of the mark:

1.

Loosen

1

⁄

2

-inch bolts

holding the disk assembly.

For a wider mark

, increase the angle of the

marker with respect to the tube

. For a narrower

mark

, reduce the angle.

To change direction of cut (throw dirt out vs. in), invert

disk blade on hub, or invert disk assembly on tube.

2.

Tighten bolts

.

Marker Speed

The folding speed of independent markers (on separate

hydraulic circuits) is controlled by needle valves at the

cylinders.

The folding speed of sequenced dual markers is con-

trolled by an adjustment at the sequence valve.

Excessive folding speed can damage markers and void

the warranty.

Folding Speed with Needle Valves

This applies only to markers plumbed separately (left

and right are each on their own tractor hydraulic circuit).

Refer to Figure 13

A needle valve controls the folding speed. The needle

valve is near the rod end of the marker cylinder. With

tractor idling at a normal operating speed, adjust marker

folding to a safe speed.

!

WARNING

Do not adjust needle valve while marker is in motion.

!

CAUTION

Marker disks may be sharp.

Use caution when making

adjustments in this area.

Figure 12

Marker Disk Angle

11757

2

1

N

W

T

2

W

1

N

2

1

Figure 13

Needle valve Adjustment

17620