Calibration overview, Calibrate with drill raised, Calibrate for 1/10th acre or hectare – Great Plains 3PNG15 Operator Manual User Manual

Page 26: Calibration crank storage, Using calibration crank, Calibration rotations, Calibrate with drill raised calibrate for, Calibration crank storage using calibration crank

22

3PNG12 and 3PNG15

Great Plains Manufacturing, Inc.

202-553M

10/06/2008

Calibration Overview

Detailed calibration steps vary with each box. Details are

found in the Seed Rate Manual.

Some general information applies to all boxes.

Calibrate with Drill Raised

Perform the calibration with the drill hitched and raised.

Calibrate for

1

/

10

th Acre or Hectare

The number of revolutions per area depends on whether

rotating the gauge wheel, or the crank, and if the crank,

what current Drive Type. See table at bottom of page.

Calibration Crank Storage

2007 and later 3PNG drills include a calibration crank.

Earlier models rely on gauge wheel rotation.

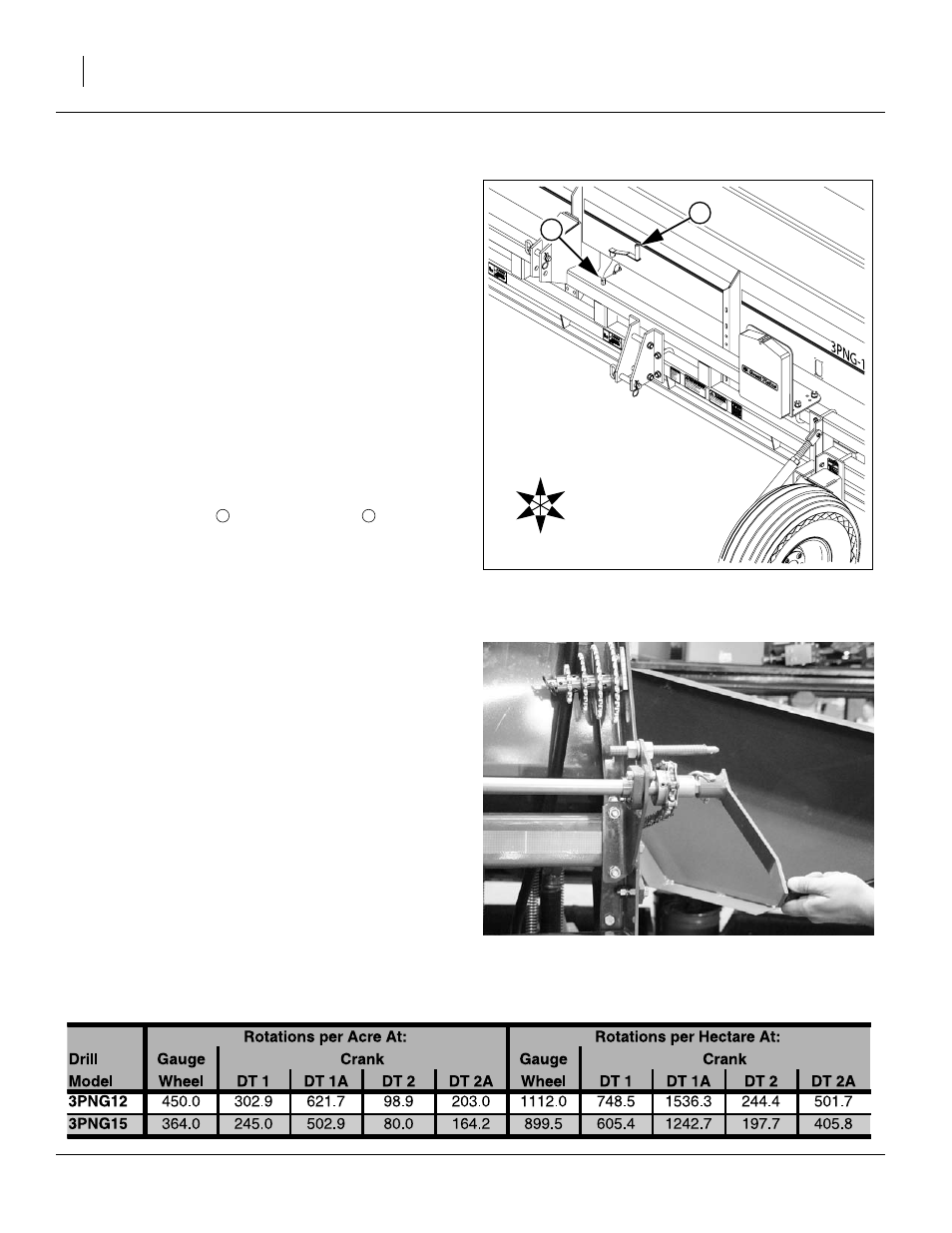

Refer to Figure 10

The calibration crank

is stored at a stob

on the top

of the front frame. It is secured by a pin.

Using Calibration Crank

Remove the cotter pin from the drive cover at the left end

of the drill.

Remove the crank from the storage stob, and use its pin

to secure it to the exposed shaft end at the forward left

end of the drill.

Use the handle to rotate the shaft counter-clockwise.

A wide range of cranking speeds produce accurate cali-

brations. For reference, at 6 mph (10 kph) field speed,

tire rpm is about 60 (about 1 revolution per second).

Calibration Rotations

Figure 10

Calibration Crank Handle Stored

28480

2

U

D

F

B

L

R

1

Figure 11

Calibration Crank in Use

23467