Cub Cadet 5252 User Manual

Page 35

35

LUBRICATION OF DRIVE SHAFT

Lubricate both ends of the drive shaft after every 50

hours of operation as follows:

•

The front end of the drive shaft can be

accessed from under the hood, and the rear

end from beneath the tractor. NOTE: It may be

necessary to rotate the drive shaft to access

the grease fittings.

•

Using a pressure lubricating gun, lubricate the

drive shaft with Cub Cadet 251H EP grease.

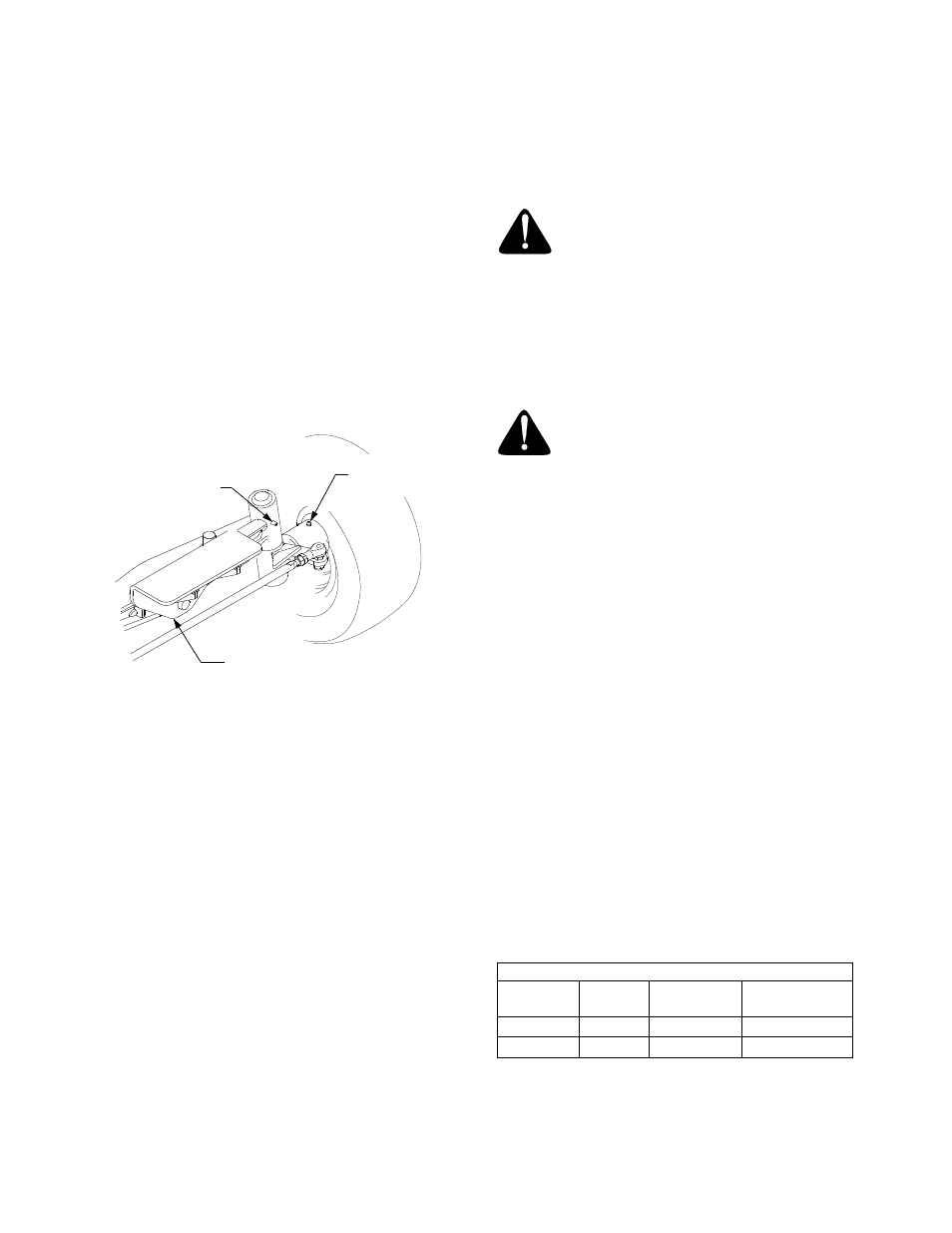

LUBRICATION OF FRONT AXLE

Lubricate the front axle pivot pin, steering knuckles,

and wheel hubs after every 10 hours of operation.

See Figure 44. Using a pressure lubricating gun,

lubricate the drive shaft with Cub Cadet 251H EP

grease.

Figure 44

WHEEL LUG NUT TORQUE

The front wheel bolts and rear lug nuts should be

retorqued after the first ten hours of operation and

every 100 hours thereafter, or if the wheel assembly

has been removed. Using a torque wrench, retighten

the lug bolts and lug nuts as follows:

Rear Wheels—In a staggered pattern, retorque the

rear wheel lug nuts to 60-70 ft. lbs.

Front Wheels—In a staggered pattern, retorque

the front wheel lug bolts to 60-70 ft. lbs.

TIRE MAINTENANCE

Check the tire air pressure after every 50 hours of

operation or weekly. Keep the tires inflated to the

recommended pressures. Improper inflation will

shorten the service life of a tire. See the tire side

wall, or the Tire Inflation chart, for proper inflation

pressures. Observe the following guidelines:

•

Do not inflate a tire above the maximum

pressure shown either on the sidewall of the

tire or the Tire Inflation chart.

•

Do not reinflate a tire that has been run flat or

seriously under inflated. Have a qualified tire

mechanic inspect and service the tire.

WARNING: Servicing tires can be dan-

gerous. Whenever possible, trained

personnel should service and mount

tires.

If you must service the tires, observe the following

safety precautions to avoid an injury or fatality:

•

Make certain the rim is clean and free of rust.

•

Lubricate the flanges of the rim and beads of

the tire with soap solution.

WARNING: When seating the beads,

never inflate a tire over 35 PSI. Inflat-

ing a tire with unseated beads beyond

35 PSI could break the bead or rim with

sufficient explosive force to cause a

serious injury.

•

Inflate the tire to seat the beads. If the tire

beads have not seated at or before 35 PSI,

allow the tire to deflate. Reposition the tire on

the rim, lubricate the tire beads and rim flanges,

and reinflate until seated - up to a maximum of

35 PSI.

•

After the beads have seated, adjust the infla-

tion pressure to the recommended operating

pressure.

•

Do not use a damaged rim, or attempt to repair

a rim by brazing, welding, or pounding out.

•

Make certain the jack used to raise the tractor

has a weight capacity adequate for lifting the

tractor.

•

Place the tractor on a firm, level surface and

position jack stands to support the raised

tractor while repairing tires.

•

DO NOT place any part of your body beneath

the tractor or start the tractor engine while the

tractor is raised off the ground with a jack.

PIVOT PIN

LUBE FITTING

STEERING

KNUCKLE

LUBE FITTING

WHEEL HUB

LUBE FITTING

TIRE INFLATION CHART

Position

Tread

Type

Tire Size

Inflation

Pressure

Front

Turf

18 x 8.5-8

15 psi

Rear

Turf

26 x 12-12

10 psi