Clutch shaft & miter gear alignment, Seed rate adjustments – Great Plains EWNT7 1237Q-1522Q Operator Manual User Manual

Page 14

EWNT7 and EWNT10 End Wheel No Till Drill 150-082M

4/17/2001

12

Great Plains Mfg., Inc.

Section 4 Adjustments

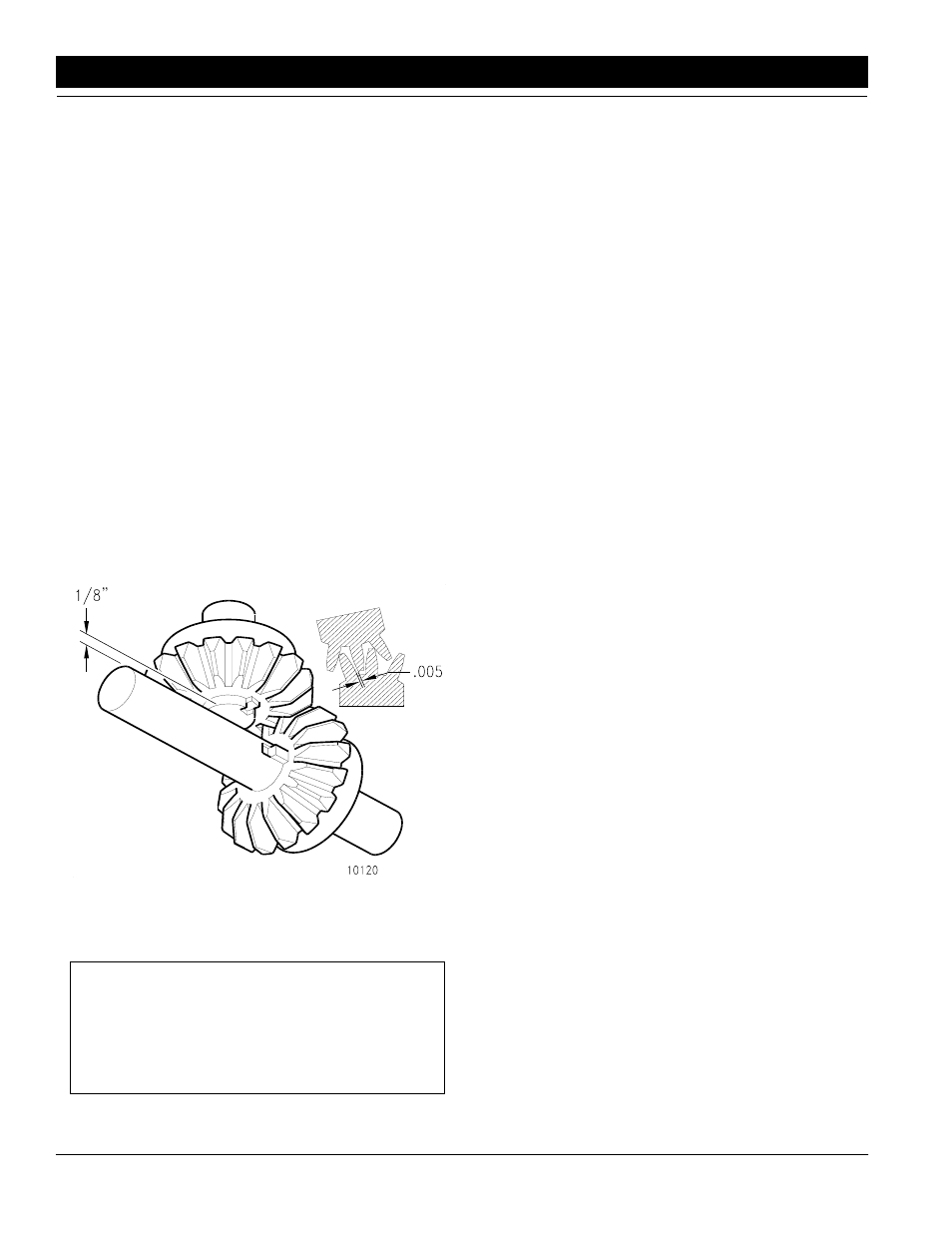

Clutch Shaft & Miter Gear Alignment

Refer to Figure 4-3:

The speed change box is designed to give you a variety

of speeds for different types of seeds and rates. It is a

linear shift pattern design with constant mesh gearing

and totally sealed to keep the dirt out. There should be

no lubrication required unless service is needed. The in-

put shaft is located on the bottom of the box and is driven

with mitered gears. It is recommended that lubrication

not be applied to the gears. If the gears are lubricated

the lubrication will attract dirt and increased wear will re-

sult. It is very important that the mitered gears back lash

is set correctly. Using a (.005) wire type feeler gauge or

a piece of wire measuring (.005) in diameter, insert it be-

tween the teeth of the two gears where they mesh, Fig-

ure 4-3. The adjustment is done by loosening the set

screws in the bearing on the jack shaft nearest the gear.

Loosen the bearing bracket mounting bolts under the

gearbox. Then slide bearing bracket, bearing and gear

over to gear on the gear box input shaft with wire gauge

inserted between the teeth and tighten the bearing set

screws, then tighten the bearing bracket mounting bolts.

After adjustments are made, rotate the jackshaft to see

that no binding occurs within the gears.

Seed Rate Adjustments

10120

Speed Change Miter Gears

Figure 4-3

NOTE: Seeding rates will vary greatly with variations

in sizes of the seeds. Although the seeding rates list-

ed in this manual are based on an average seed

size, we recommend that you test and adjust your

drill using the procedures listed below to help insure

an accurate seeding rate.

Refer to Figure 4-4:

1.

To adjust your seeding rate, first you must decide

which drive type you need (see "Seed Rate Charts"

on the following pages). In order to change drive

types, move the lever on the speed change box to

desired setting, Figure 4-4.

2.

There are many factors which will affect seeding

rates: seed treatment, weight of seed, size of seed,

surface condition of seed, and tire configuration,

pressure and slippage. Minor adjustments will prob-

ably be needed to compensate for the above factors.

3.

The pounds-per-acre in the seed charts are based

on drills having 9.00 x 24 rib implement tires with

proper inflation as listed on page 6.

4.

The large differences in seed size and treatment can

cause a wide variation in actual seeding rates. The

seed rate charts on the following pages are based

on average size seed. This may differ from the seed

you are using. Use the seed rate charts as a guide.

Set the pounds-per-acre desired at the indicator

number for your row spacing and complete the fol-

lowing procedure to calibrate the drill for your specif-

ic seed.

a.

Lower the drill hydraulically to planting position

in order to activate the clutch.

b.

Raise the drive (left) end tire off the ground us-

ing a jack.

c.

Rotate the tire to see that the drive system is

working properly and that the feed cups are free

from foreign matter.

d.

Place several pounds of seed over three of the

feeder cups at the outboard end of the seed box.

Make sure all feed cup handles are set in the

same position on all the feeder cups.

e.

Set the feed cup adjustment lever to the desired

setting.

f.

Pull the seed tubes out of these openers.

g.

Place a container under the three seed tubes to

gather the seed as it is metered.

h.

Rotate the drive gauge wheel until one acre has

been tallied on the acremeter. This will be ap-

proximately 422 rotations on a 10’ drill and 592

rotations on a 7’ drill. Be sure to check the three

feeder cups to make sure each cup has plenty of

seed coming into it.

i.

Weigh the seed which has been metered. Di-

vide by three. This will give you the ounces/

pounds metered by each feeder cup. Multiply by

the number of openers on your drill to arrive at

the total pounds-per-acre you would meter at

that setting. If this figure is different than de-

sired, set your feed cup adjustment lever ac-

cordingly.