4 double disc roller, 5 work settings, 1 levelling boards – Great Plains Simba UniPress Operator Manual User Manual

Page 26

26

Simba UniPress

607-114M-ENG

2013-01-25

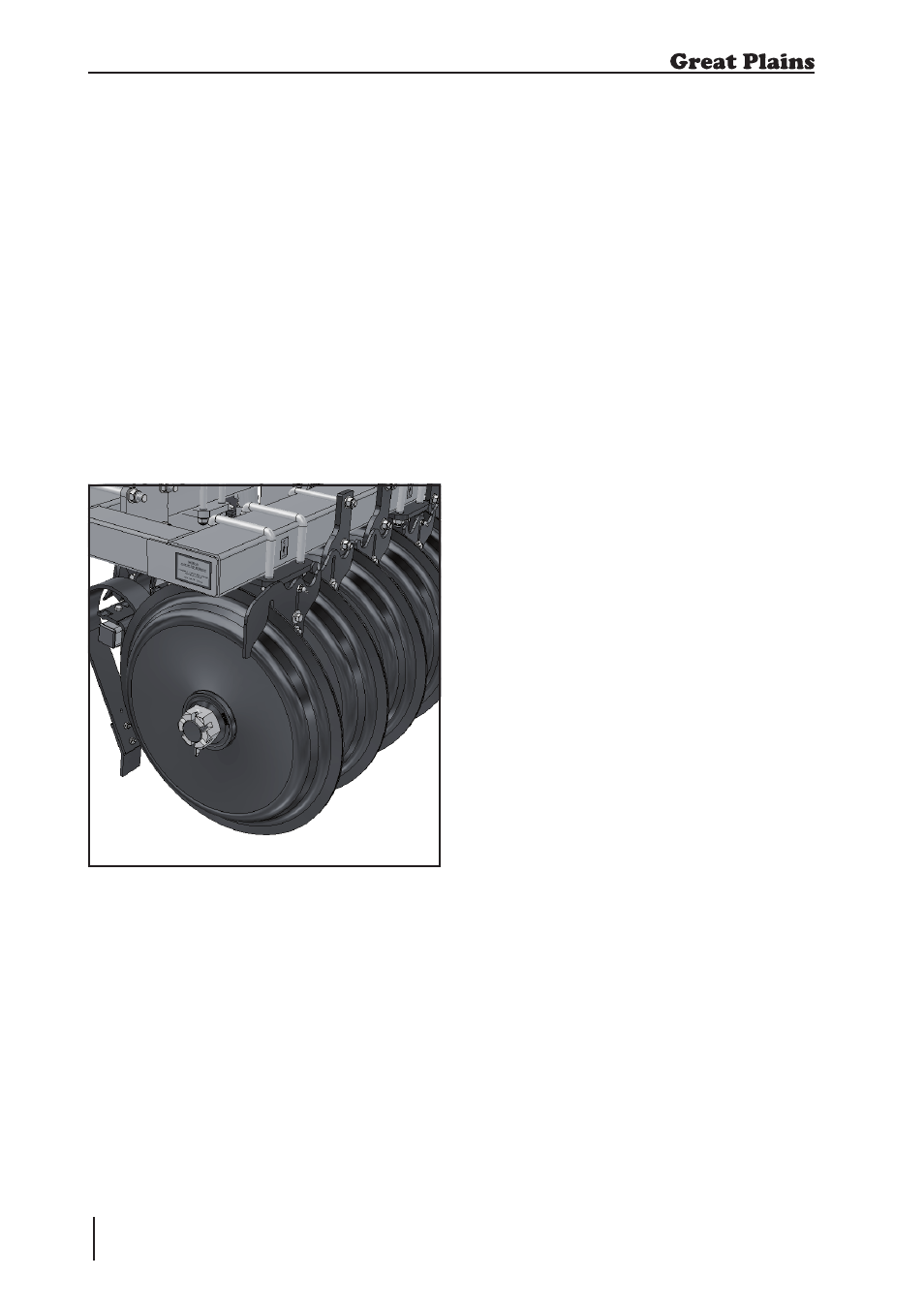

4.4 Double Disc Roller

The standard DD700 roller is made up of

individual Double Disc (patented) Ring

segments.

The DD rings are designed to consolidate

the soil whilst cutting and crushing any clods.

Even in heavy, wet soils it can easily be

operated with minimal blockages occurring.

The DD roller carries a proportion of the

machine’s weight to ensure consolidation.

The corrugated surface left by the roller is

weatherproof both for wet or dry situations.

Fig. 4.04: Double Disc Roller

4. Adjustment / Operation

4.5 Work Settings

In work the wing cylinders should be fully

extended. The gangs are able to float over

any undulations on the ground due to their

floating frames.

Optimum performance has been found

to be achieved when the press roll rings

have worn away the painted finish leaving

a smooth shiny surface. When the press

roll rings are new or rusty, soil may tend to

pick up on the surface and blockage may

occur, this will reduce when the rings are

shiny again.

The Simba UniPress should be run with the

chassis level front to rear by extending the

drawbar cylinders to the necessary position.

The cylinders should not be over extended

as this will remove the load on the rings

which could lead to reduced drive and hence

blockage of the axles.

It is not necessary to tilt the Simba

UniPress onto the transport wheels during

headland turns whether the machine is

used independently or in tandem with a disc

cultivator. Normally, the Simba UniPress

should be tilted sufficiently onto the roll for

the tines and levelling boards to clear the

ground (at which point the rear axle wheels

will still be clear of ground contact).

4.5.1 Levelling Boards

The levelling boards are set using shims in

the levelling board cylinders. During work,

these cylinders should be retracted onto the

shims but can be extended to release any

soil / trash build up.

With the chassis set level add shims until the

levelling boards are carrying soil. The level-

ling boards will need to be set higher during

1st pass operations especially on ploughed

land where large clods may not be able to

pass under or between the sprung leaves.