Seeding rate, Adjust drive sprockets, Set seed rate handle – Great Plains 2420F Operator Manual User Manual

Page 36

1520F, 2020F, 2420F, 1510HDF, &

2010HDF

8/14/2006

34

Seeding Rate

Adjusting the seeding rate requires the following:

1.

adjusting drive sprockets,

2.

setting seed-rate handle,

3.

positioning seed-cup doors,

4.

checking seeding rate.

Refer to the seed rate charts on page 37. These

charts list proper sprocket sizes and seed rate

handle settings for various seeds and seeding

rates.

The seed rate charts are based on cleaned, un-

treated seed of average size and test weight. The

charts are based on 9.5L x 15 rib implement tires

for 15ft drills and 11L x 15 rib implement tires for

20ft and 24ft drills.

Many factors will affect seeding rates including

foreign material, seed treatment, seed size, seed

weight, field conditions, and tire pressure. You

likely will need to make minor adjustments. Set

and check the seeding rate, then readjust the rate

as necessary.

Before setting the seeding rate, rotate the gauge

wheels. Check that seed cups and drive are work-

ing properly and free from foreign material.

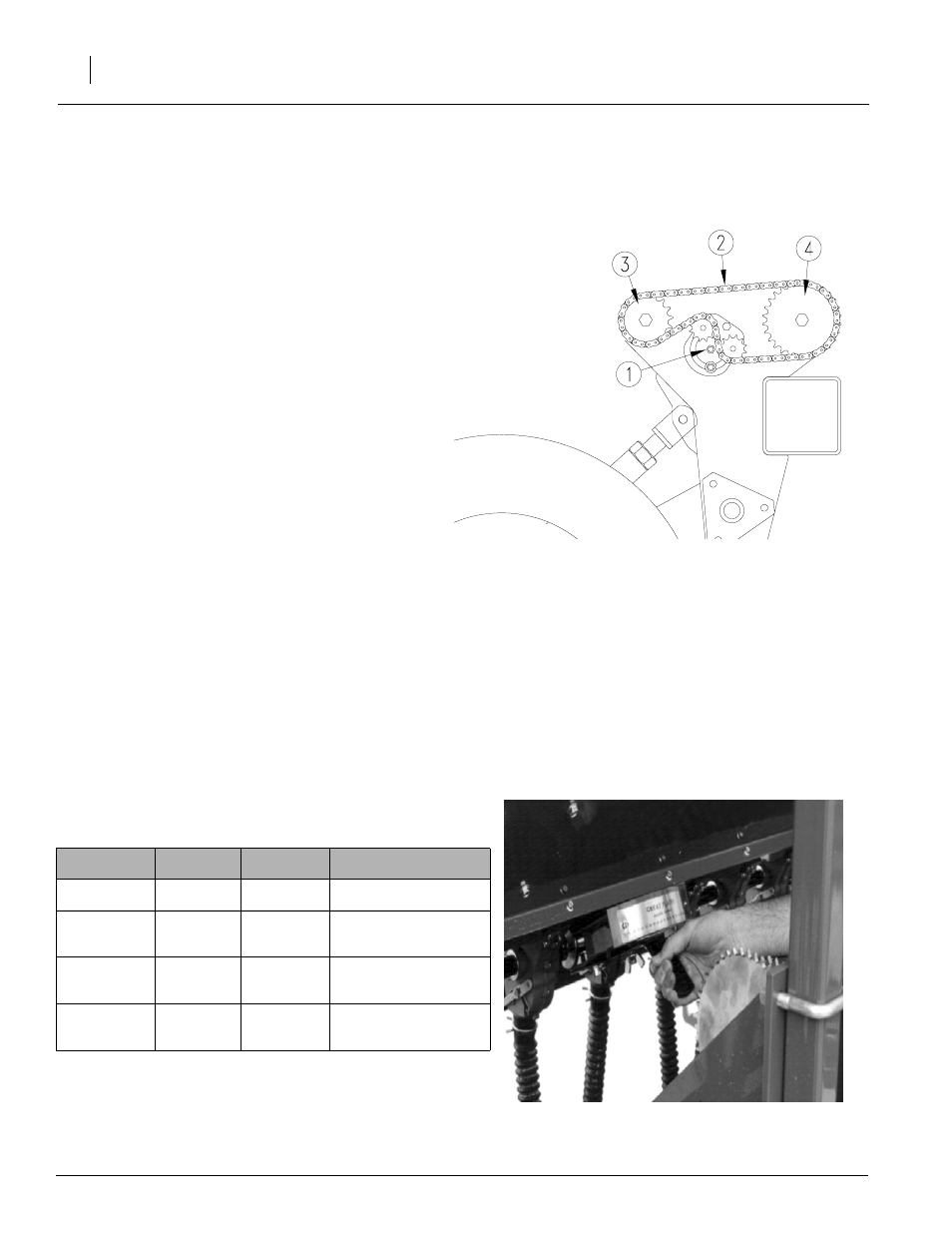

Adjust Drive Sprockets

Install drive sprockets for the drive type for your

desired seeding rate.

For correct drive type, refer to seed rate charts be-

ginning on page 18. The charts list drive types as

1, 2, 3, or 4. Refer to the following table for the cor-

rect-sized sprocket for each drive type.

Drive Type

Driver

Driven

Speed

Type 1

14 Tooth

44 Tooth

Slowest

Type 2

24 Tooth

36 Tooth

Two Times Faster

Than Type 1

Type 3

24 Tooth

24 Tooth

Three Times Faster

Than Type 1

Type 4

24 Tooth

15 Tooth

Five Times Faster

Than Type 1

To change drive sprockets, refer to Figure 5. Loos-

en idler plate (1) and remove drive chain (2) .

Remove lynch pins from shafts and rearrange

driver (3) and driven (4) sprockets.

Reroute drive chain over sprockets and idlers as

shown in Figure 5. Move idlers into chain so

chain has 1/4-inch slack in its longest span.

Tighten idlers.

17669

Set same drive type on both drill sections.

Set Seed Rate Handle

Position seed rate handle for each drill box as in-

dicated on seed rate chart. One handle is shown

in Figure 6.

To adjust seed rate handle, loosen wing nut un-

der handle. Slide handle until indicator is just past

the correct setting. Retighten wing nut.

Figure 5

Driver and Driven Sprockets

17618

Figure 6

Seed Rate Handle