General operation and in-field adjustments, Prior to operating the turbo max, Hitch turnbuckle – Great Plains 4000TM Operator Manual User Manual

Page 34: Prior to operating the turbo max hitch turnbuckle, General operation and in-field adjust- ments

30

1200-4000TM

Great Plains Manufacturing, Inc.

586-288M

10/30/2012

General Operation and In-Field Adjust-

ments

Prior to Operating the Turbo Max

11. Raise the machine fully so the lift cylinders

no longer rest

on the transport lock channels

Remove transport lock channels and store on the bars

above. Remove the wing transport pins

and store in the spools

on the wing rest bar. Open the

wing fold valve

located under the depth stop adjustment

(Models 1800-3000) or on the bypass/down pressure valve

(Models 3500-4000). You are now ready to unfold unit.

12. Unfold unit being sure that the fold cylinders are fully

extended. You may increase flow rates during the folding

and unfolding procedure but be sure to slow the flow rates

back down once the unit is unfolded.

13. When operating the Turbo Max with the blades running at

an angle, it is generally unnecessary to operate with

hydraulic down pressure to the wings. Only in very hard

ground will down pressure be needed. If down pressure is

needed, see “Hydraulic Down Pressure 1800-3000” on

page 23, “Hydraulic Down Pressure 3500” on page 24 or

“Hydraulic Down Pressure 4000” on page 25 for initial

setup. If no down pressure is needed, set the fold hydraulic

system to the "FLOAT" position at this time.

14. When operating the blades in the straight position, down

pressure is necessary, usually between 200 and 400 psi.

Note: Never leave tractor valve centered when unfolded with

machine in motion. Machine damage may occur when

wings flex. The hydraulic down pressure cylinders have

no wing flex capability and oil flow is required when the

wings flex up or down. You must have the tractor fold hy-

draulic lever in continuous downward flow or “FLOAT” po-

sition before the wings can flex over terrain in the raised

or lower lift position.

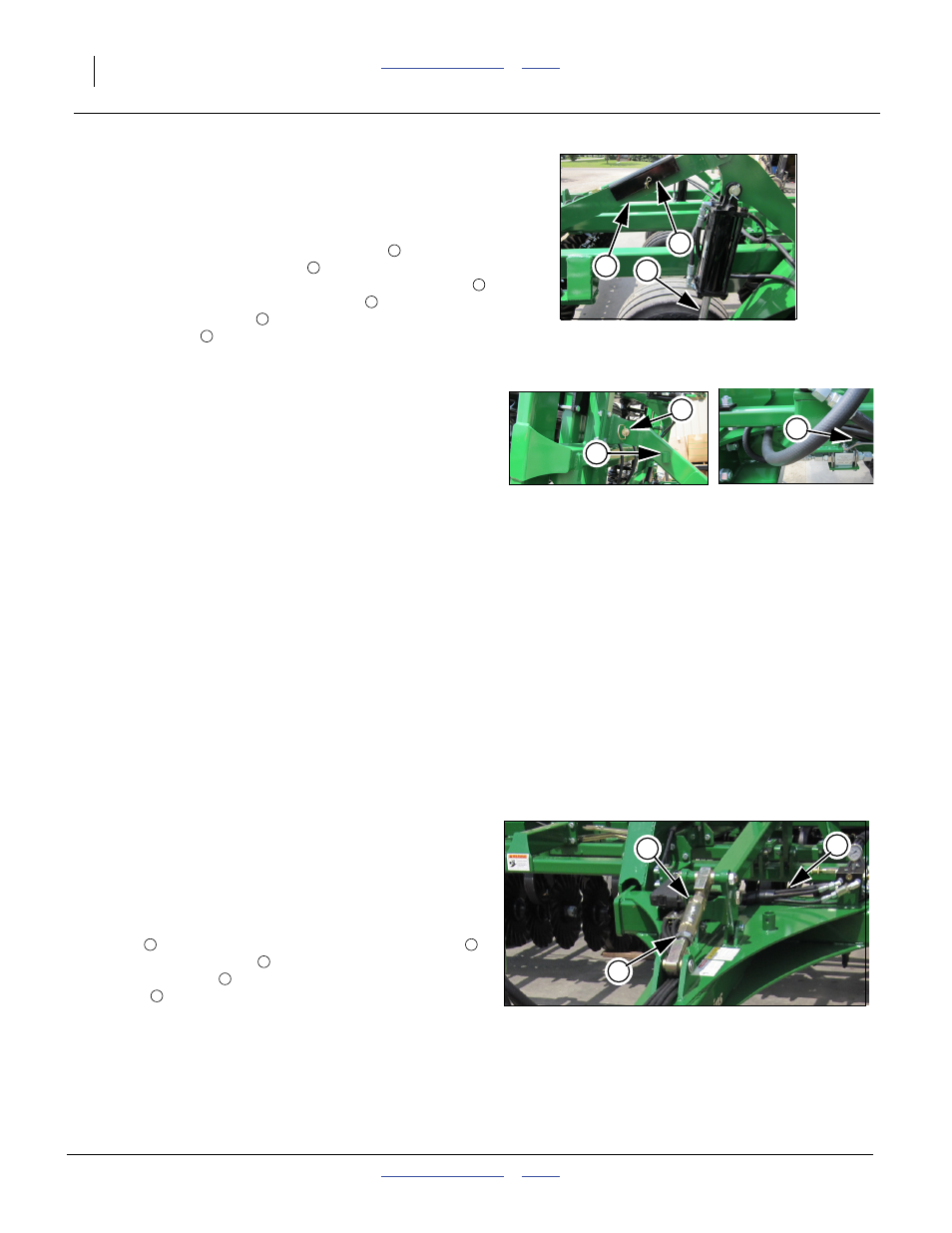

Hitch Turnbuckle

Note: If possible have someone observe the machine during

the initial operation for levelness - both front to rear and

center to wings. Adjust each as needed.

Refer to Figure 30

15. For front to rear, either extend or shorten the front turn-

buckle

on the leveling system by loosening jam nut

with turnbuckle wrench

(stored on rear pegs of hitch).

Adjust turnbuckle

until level front to back. Re-tighten

jam nut

after machine is level. Never run the machine

lower (deeper) in the rear than in the front.

Figure 28

Transport Locks

42066

1

2

3

1

2

3

4

5

6

Figure 29

Wing Fold

4224

4225

5

4

6

Figure 30

Hitch Turnbuckle Adjustment

42260

1

2

3

1

2

3

1

1