Step 12: 5 revolution test, 4step 13: summary screen, Step 11: clutch folding module operation – Great Plains YP4025A-3115 31-Row 15-Inch Quick Start User Manual

Page 4: Step 9: accessory sensor setup, Step 10: clutch folding module (cfm) setup

Quick Setup Guide for IntelliAg Model YP40 15” Air Pro

11001-1539-200909

©2009 DICKEY-john Corporation

Specifi cations subject to change without notice.

STEP 12: 5 Revolution Test

Press the Control Setup button

.

Press the Channel Setup button

.

Press the Next Page button

.

Ensure implement is raised before starting 5 Rev Test.

With brakes locked and transmission in PARK position, start tractor engine.

Engage hydraulics and run engine at normal speed until hydraulic fl uid is at operating

temperature.

Press the 5 Rev button

.

Test Ground Speed and Row data must be entered to perform test.

Press and hold remote test button to initiate 5 Rev Test.

1.

2.

3.

4.

5.

6.

7.

8.

9.

4

STEP 13: Summary Screen

The Summary screen provides an overview of setup constants for active control channels.

At the Main Work screen, press the Next Page button

.

Press the Summary button

To view specifi c control channel confi gurations, press the respective control channel

box 1-4.

Press inside a yellow highlighted box to open a specifi c screen for editing.

Press the Work Screen button

to return to the Main Work screen.

1.

2.

3.

4.

5.

Summary

Screen

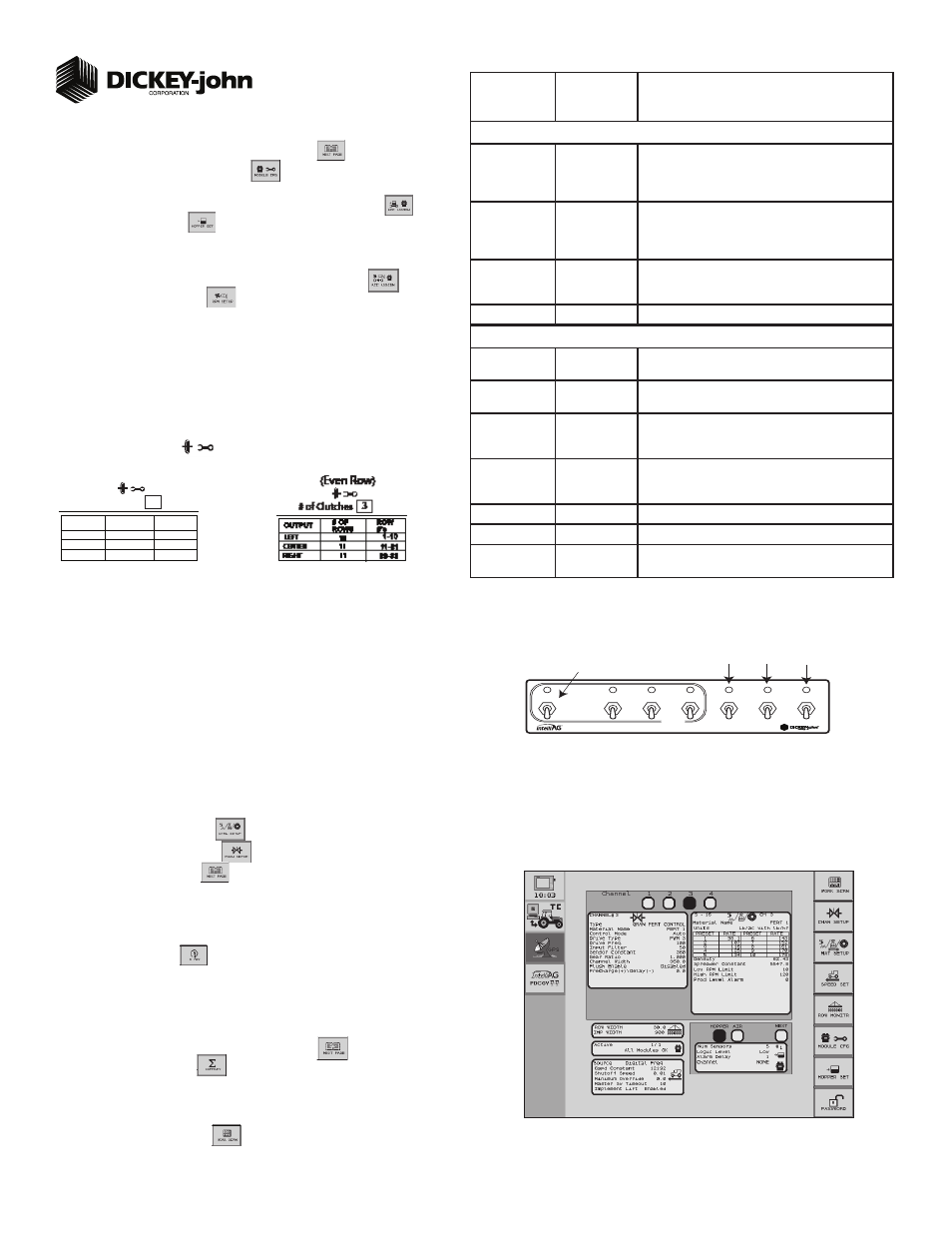

STEP 11: Clutch Folding Module Operation

The planter section controls turn the left, center, and right clutch controls on and off.

The master switch must be in the ON position to activate any planter section. When a

clutch control is ON, a green light will illuminate.

Marker/Fold Switch should be in the UP (Marker) position during planting. In the

DOWN (Fold) position, the switch controls the fold of the main frame.

The fertilizer pump switch is turned ON when in the UP position. Press the switch in the

DOWN position to turn OFF.

Lift/Hitch switch should be in the UP (Lift) position during normal operation. In the hitch

position, the switch should be in the DOWN (Hitch) position to unlock and extend the

telescoping tongue in preparation of folding the implement for transport.

Lift/Hitch switch MUST be in the hitch position and hydraulic circuit in FLOAT when

transporting planter equipped with hydraulic-operated tongue hitch. NOTE: Lift/Hitch

switch has no function if planter has standard 3-point hitch operated tongue hitch.

1.

2.

3.

4.

5.

6.

MASTER

Left Center Right Marker Fert. Pump Lift

MASTER

MASTER

CLUTCH

Fold Hitch

Master

CFM Switch

Marker

or

Fold

Fertilizer

Pump

On/Off

Lift

or

Hitch

TABLE F:

Accessory

Setup

Default Value

or Value to

Enter

Instructions/Defi nitions

Hopper Setup

# of Hoppers

1 (base unit)

1 more (optional)

# of hopper sensors connected to each module (4 sensors

maximum). # of hopper data items for each listed module

and the Hopp #’s value will automatically populate if Auto

Confi g is used to confi gure installed sensors.

Logic Level

Active Lo

Sets the active state to low signifying that an alarm is gener-

ated if the sensor’s output is in a low state. Use this setting

if the connected sensor outputs a low condition when empty

similar to the DICKEY-john hopper sensor.

Alarm Delay

5 sec

Controls the delay time between the detection of a high/low

hopper alarm condition and the generation of the resulting

alarm. The value is entered in seconds.

Channel

Assigns hopper sensor to channel.

RPM Setup

High Alarm

(fan speed)

3000 rpm

Sets the RPM value at which a high RPM warning error is

generated.

Low Alarm

(fan speed)

1800 rpm

Sets the RPM value at which a low RPM warning error is

generated.

High Alarm Delay

10 sec

Establishes the delay between the detection of a high RPM

alarm condition and the resulting alarm display. The value is

entered in seconds.

Low Alarm Delay

10 sec

Establishes the delay between the detection of a low RPM

alarm condition and the resulting alarm display. The value is

entered in seconds.

RPM Constant

3 pulses/rev

Number of pulses per sensor revolution.

RPM Filter

0

Filters the signal out of the RPM sensor.

Disable Control

on Low Alarm

Disabled

Allows for disabling of all control channels if the RPM value

of the selected sensor falls below the low alarm level setting.

STEP 9: Accessory Sensor Setup

Hopper Assignment

At the Main Work screen, press the Next Page button

.

Press the Module Confi guration button

to display the Module Confi guration

screen.

At the Module Confi guration screen, press the Hopper Assign button

.

Press Hopper Set button

.

Enter desired values using Table F as reference.

RPM Assignment

At the Module Confi guration screen, press the Acc Assign button

.

Press the RPM Setup button

.

Enter # of RPMs, if required. NOTE: There must be at least 1 RPM sensor confi gured

before the RPM Setup button appears on the screen.

Enter desired values using Table F as reference.

1.

2.

3.

4.

5.

1.

2.

3.

6.

STEP 10: Clutch Folding Module (CFM) Setup

The CFM is installed in the cab to control row clutches, marker, fold, fertilizer on/off, lift and

hitch.

At the Main Work screen, press the Clutch CFG button to access the Clutch Confi gura-

tion screen and verify that the correct # of clutches are confi gured for the system.

The Clutch CFG button

only appears as a top level button when a planter

output module and clutch folding module are installed.

1.

2.

O U T P U T

1 - 1 0

# O F

R O W S

R O W

# ’s

11 - 2 1

2 2 - 3 1

LEFT

CENTER

RIGHT

10

11

10

# of Clutches 3