Great Plains 1006NT Material Rate User Manual

Page 27

Great Plains Mfg., Inc.

25

04/20/2007

150-287B

11. Rotate gauge wheel or calibration crank one acre.

See table at right for revolutions per acre.

Note: You can also rotate the gauge wheel jackshaft by

means of a wrench or socket. If rotating gauge

wheel jackshaft, disengage the lockout on the

drive wheel and use same number of rotations as

for rotating drive wheel.

12. Check that the three seed cups have plenty of

seed coming into them.

13. Weight metered seed. Subtract initial weight of

container. Divide by three. Multiply by the number

of openers on the drill to determine total pounds

seeded per acre. If this figure is different than

desired, change your sprockets and drive type

accordingly.

Note: You may want to repeat the calibration procedure

if your results vary greatly from seed rate chart.

IMPORTANT !

The chart on page 26 is to be used as a reference

to your own brome grass mix. All brome grass

mixes vary so this is why you must calibrate each

mix using the chart only as a starting point.

14. When drilling, check the amount of seed you are

using by noting the acres drilled, amount of seed

added to drill, and the level of seed in the box. If

you suspect you are drilling more or less seed

than desired, and you have accurately calibrated

the drill to your seed, you may need to change

your sprocket arrangement to compensate for your

field conditions.

Factors which will affect seeding rates are: weight of

seed, size of seed, relative humidity and moisture con-

tent of seed, ratio of inert material to seed, different

proportions of seed types affecting density, tire config-

uration, tire pressure, and tire slippage.

All seed mixes will vary.

The rates are based on 9.00 x 24 8-Ply tires.

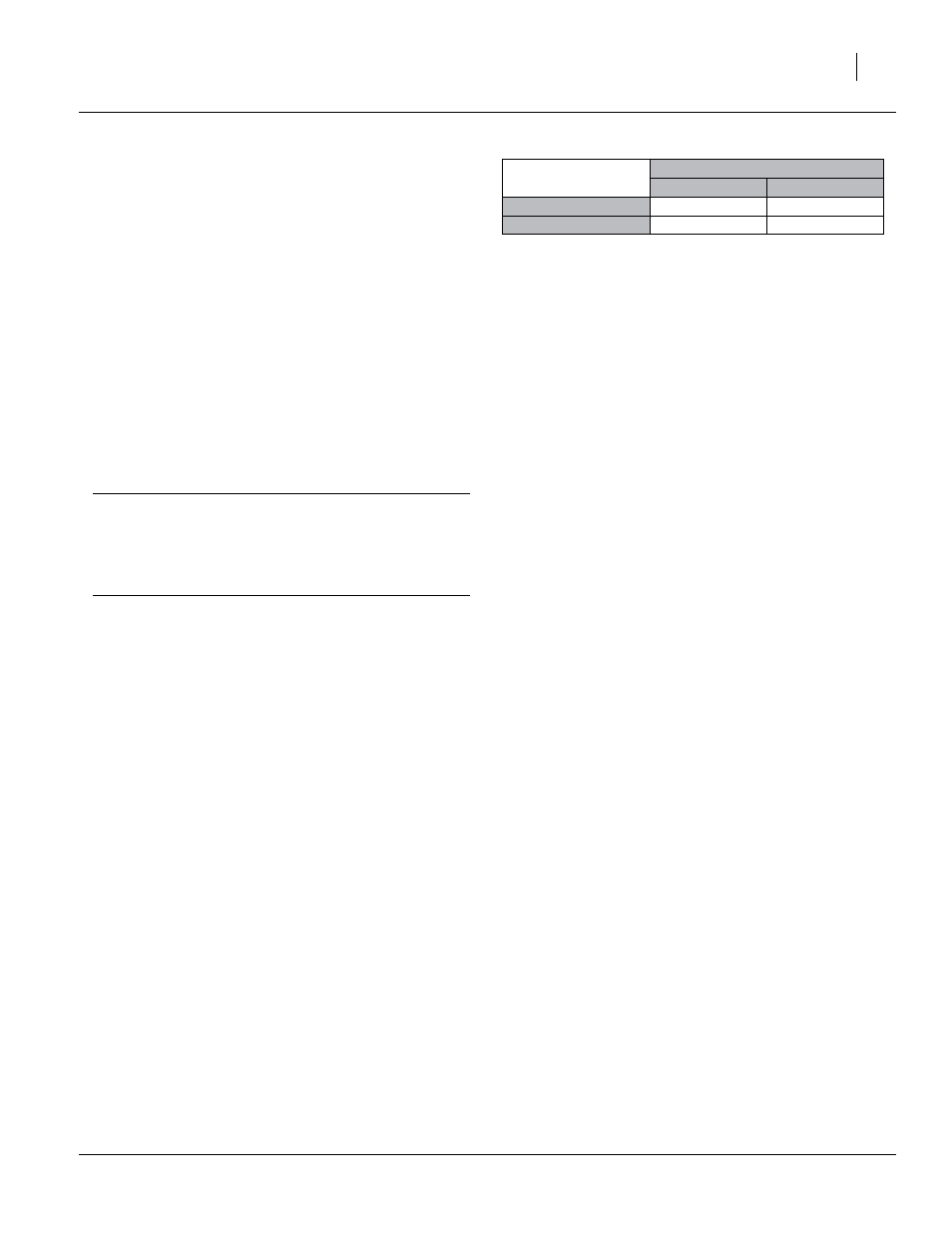

Drill

Model

Revolutions for One

Acre

Hectare

706NT

595

1470

1006NT

411

1016

MeasuredSeed

EmptyContainer

–

3

----------------------------------------------------------------------------------

PoundsPerSeedCup

=

PoundsPerSeedCup

NumberOfOpeners

×

PoundsPerAcre

=