Great Plains 1006NT Material Rate User Manual

Page 23

Great Plains Mfg., Inc.

21

04/20/2007

150-287B

11. Weigh metered seed, and subtract the initial

weight of the container. Divide this number by 3

(number of cups metered). Finally, multiply by the

number of openers on the drill. This equals the

pounds per acre at this drive setting. Refer to the

formulas on the right.

Note: Refer to the drive setting chart on page 23,

the numbers listed are the number of revolu-

tions of the native grass meter shaft at a par-

ticular drive type and sprocket range.

12. To adjust this number, take the pounds per acre

divided by the shaft revolutions. This is the pounds

per shaft revolution.

13. Divide desired rate of pounds per acre by the

pounds per shaft revolution (this is the number

obtained from step 12). Find this number (or the

closest number to this) in the drive setting chart.

This will give the gearbox drive type and the range

sprocket size.

14. Set the Drive Type lever to the chart value.

15. Determine which sprocket is required for the native

grass box. The sprockets are stored on the right-

hand side of the drill frame.

To change sprockets, loosen the chain idlers.

Replace with desired sprocket.

Note: All native grass mixes will vary in weight,

seed type, and density, so this is why you

must calibrate each mix.

16. When drilling, check the amount of seed you are

using by noting the acres drilled, amount of seed

added to drill, and the level of seed in the box. If

you suspect you are drilling more or less seed

than desired, and you have accurately calibrated

the drill to you seed, you may need to change your

sprocket arrangement to compensate for your field

conditions.

MeasuredSeed

EmptyContainer

–

3

----------------------------------------------------------------------------------

PoundsPerSeedCup

=

PoundsPerSeedCup

NumberOfOpeners

×

PoundsPerAcre

=

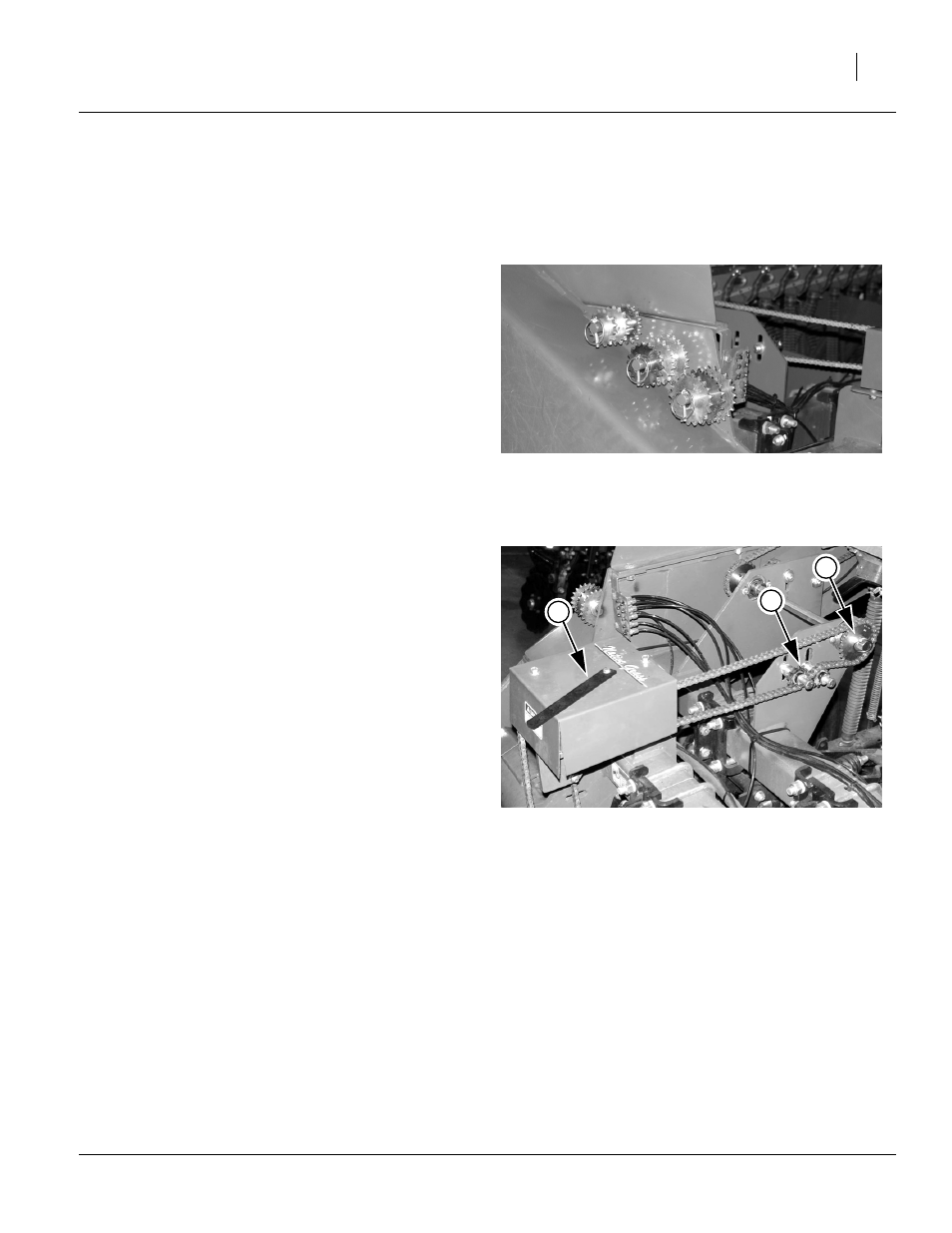

Figure 10

Select NG Driven Sprocket

20483

Figure 11

Set Native Grass Drive Type

20484

2

1

3