Servicing and maintenance, 1 servicing, 2 cleaning – Great Plains ST-Bar Operator Manual User Manual

Page 18: 3 storage / parking, 4 tines

18

Simba ST-Bar

606-037M-ENG

2012-12-21

Ensure the machine is safely

supported before attempting

maintenance work on tines. With

the machine attached to the tractor

it can be lowered onto the parking

stands for tine maintenance.

Do not attempt to assist fitting tine

points with a steel headed hammer,

this can lead to splintering of the

metal due to its hardness, which

can cause injury. If tine fitting

requires assistance, a copper/

hide or plastic mallet should be

used.

Ensure the tine leg is supported

when removing pins to ensure it

doesn‘t fall.

5. Servicing and

Maintenance

Follow the safety instructions for

servicing and maintenance.

5.1 Servicing

Your Simba ST-Bar unit has been designed

and constructed for maximum performance,

operational efficiency and operator

friendliness under a wide variety of operating

conditions.

Prior to delivery, your Simba ST-Bar has

been checked at the factory and by your

authorised dealer to ensure that you receive

it in optimum condition.

To ensure trouble-free operation, it is

important that servicing and maintenance

work is performed at the recommended

intervals.

5.2 Cleaning

In order to ensure that the Toolbar is always

in operating condition and to achieve

optimum performance, perform the cleaning

and servicing work at regular intervals.

5.3 Storage / Parking

In order to avoid damage as a result of

moisture, the machine should be parked, if

possible, indoors or under cover.

5. Servicing and Maintenance

5.4 Tines

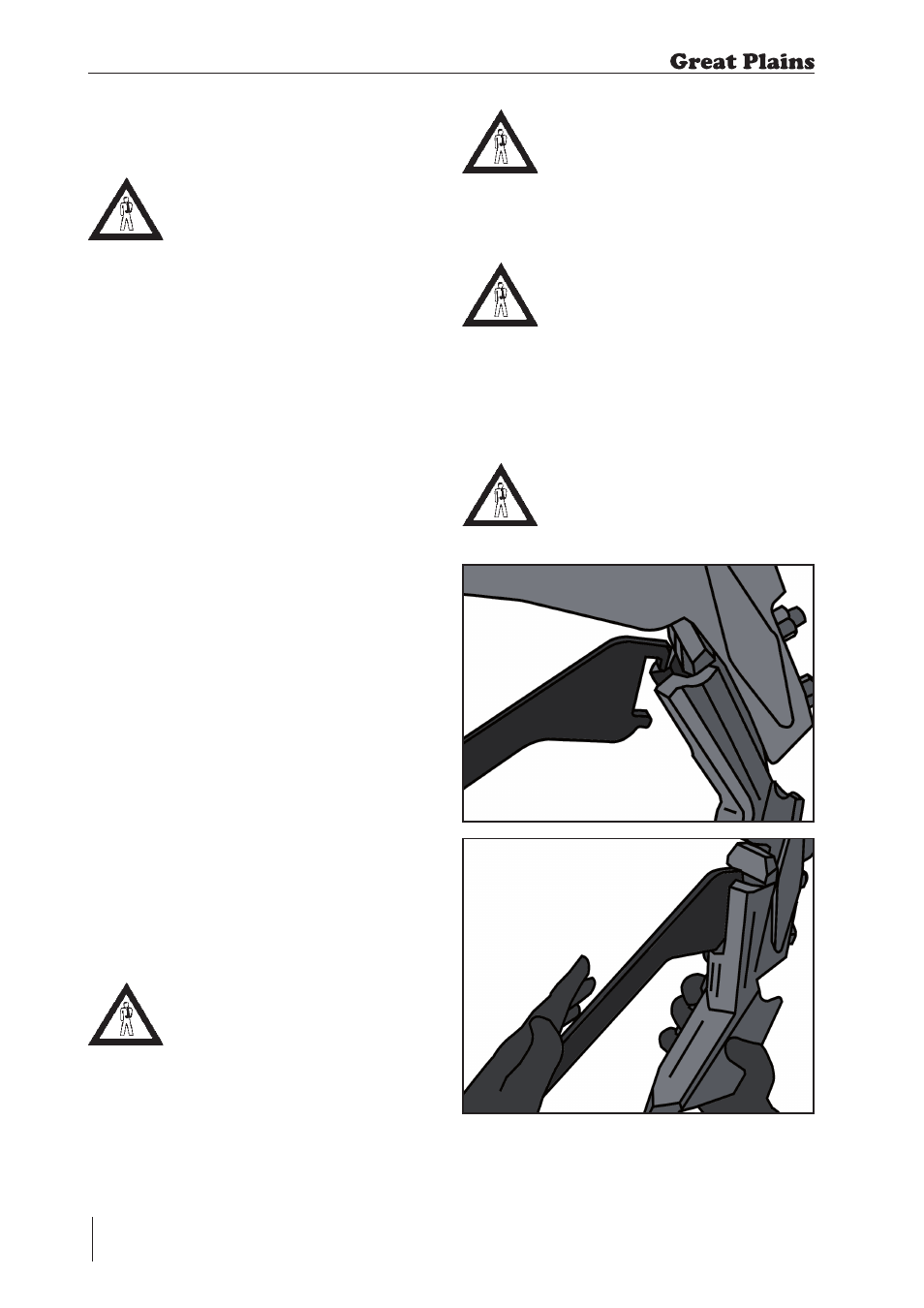

When performing maintenance

work on tines extreme care

should be taken. Wear goggles

and gloves at at all times when

maintaining tines.

Fig. 5.01: Knock-on Tine Point Removal Tool

STRIKE WITH

MALLET

ENGAGE POINT

REMOVAL TOOL