Warning – Crown Boiler 24-07 User Manual

Page 34

34

of the RTC cannot be used on multiple boiler

installations.

d. Boiler Circulator – The boiler circulator selection

will maintain a constant and minimum flow

through the boiler during every heat demand.

In addition, the circulator will maintain a flow

around the return sensor. The circulator must

be properly selected, based on the design

temperature between the boiler supply and

boiler return. Appendix B lists the appropriate

pumps for both 20 ºF and 40 ºF applications. A

boiler circulator must be used with and without

an RTC System for a primary/secondary piping

arrangement.

WARNING

If the boiler circulator you have selected is

greater than 1/3 HP, an isolation relay must

be added when using the RTC.

If a 3-phase boiler circulator has been

selected than a properly sized motor starter

must be installed when using the RTC.

e. Diverting Valve – A diverting 3-way valve must

be part of the boiler loop for boiler protection to

be active when using the RTC. Only a Crown

approved valve and actuator may be used for

boiler protection. The valve sizing does change

based on the designed boiler ∆T, since the flow

rate and the pressure drop change for each. See

Appendix B for proper valve selection.

f. Glycol Antifreeze Solutions - Many systems

today use ethylene or propylene glycol antifreeze

solutions as a measure for freeze protection, as

well as a pump lubricator and corrosion inhibitor.

The properties of the glycol mixture have an

impact on valve and pump sizing. All glycol

solutions have a lower specific heat than water.

This means that the glycol solution cannot

transfer heat as well as pure water, resulting in

the need for higher flow rates. In addition, the

viscosity of the glycol solution is usually higher

than water, requiring a higher pump head for the

same given flow. Consult factory for specific

applications, pump selection and flow rate.

g. Nipple and Sensor - The 3 x 12 special nipple

must be installed in the lower right return

connection when looking at the rear section,

when using the RTC. Insert the return sensor

using pipe dope.

2. STEAM HEATING, consult I=B=R Installation

and Piping Guide No. 200. For piping details, see

Figure 34. Figure 35 shows a typical pumped return/

boiler feed unit arrangement. Figure 36 illustrates

the required mounting elevations for McDonnell and

Miller 150 and 63 float low water cut-offs.

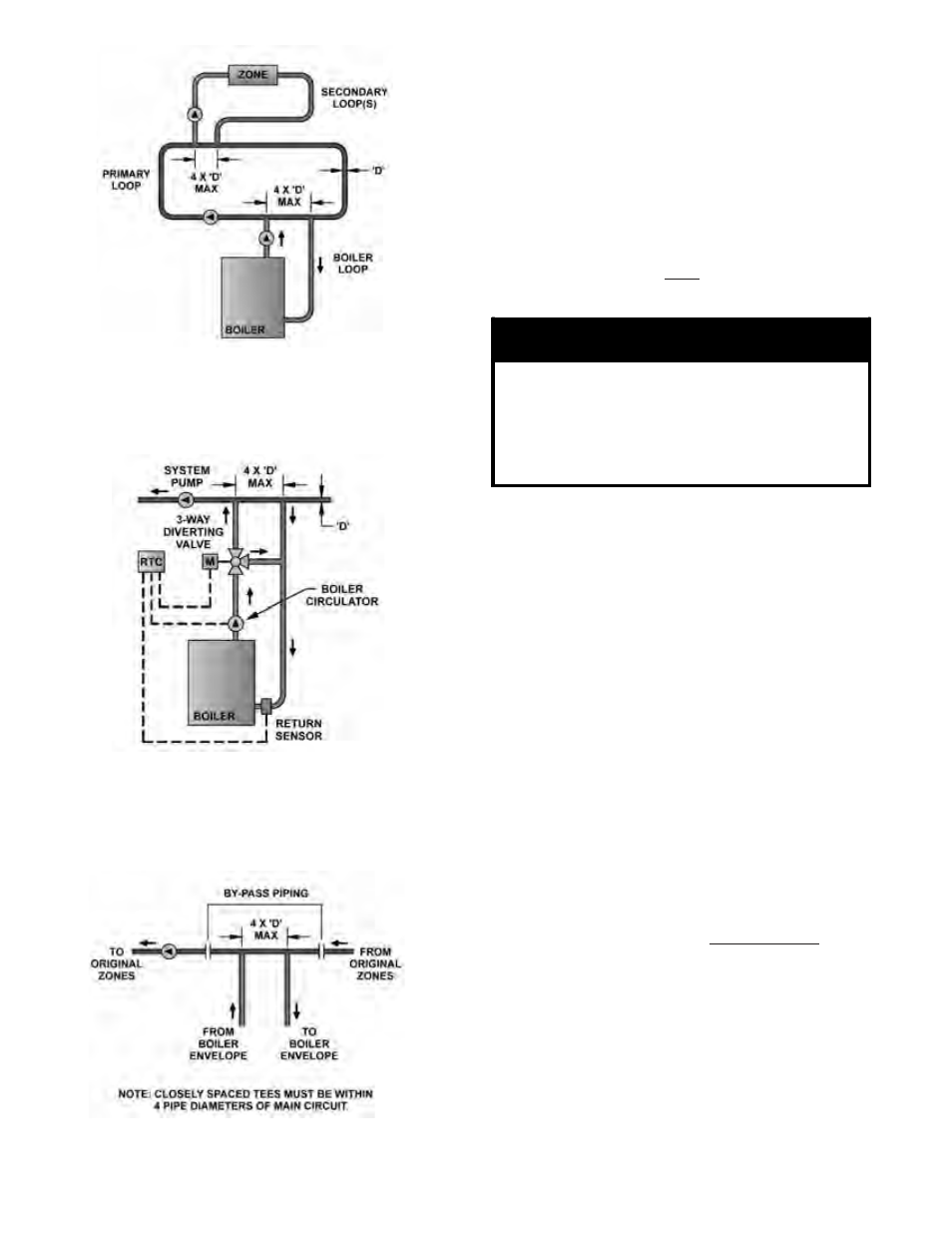

Figure 28:

Typical Crown Boiler Loop w/3-way Diverting

Valve, Where System Return may be Less than

135°F.

Figure 30: Parallel Piping Conversion

Figure 27:

Typical Crown Boiler - Primary - Secondary Loop

System (Return Temps always Greater than 135°F.)