Spring-set motor brakes, C-face motor brakes, Motor information – Wichita Clutch Motor Brakes User Manual

Page 4: Dimensions: inches

D

Spring-Set Motor Brakes

P-1100-WC 1/12

Wichita Clutch 800-964-3262 117

•

No adjustment

•

No lubrication

•

Low inertia design

•

Rugged, dependable design

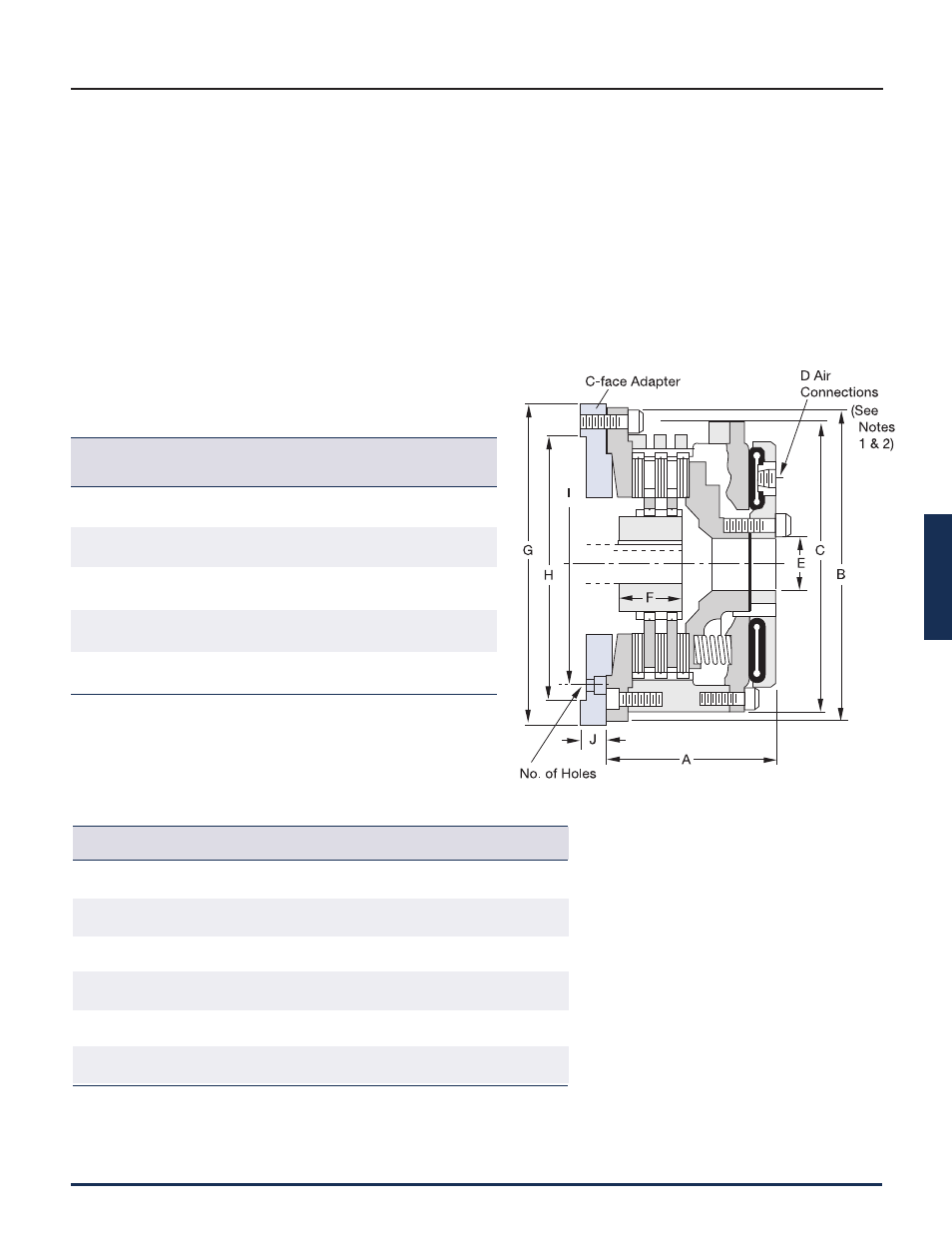

C-face adaptors are available in standard

NEMA T and U frame designs. Custom

adaptors are available for your specific motor

design. Dimensions G, H, I, J and number of

holes need to be pro vid ed to Wichita

Engineering before final design is completed.

When using Wichita C-Face Motor Brakes in a

high cycling application, brake thermal

capacity and motor thermal capacity need to

be carefully matched. The motor in for ma tion

chart lists the specific Wichita part numbers

for the proper adapter plate and brake for

C-Faced Motors up to 200 HP.

Contact Wichita Ap pli ca tion En gi neer ing for

assistance.

Notes:

1. Quick Release Valves,

see page 121.

2. Air Hose Kits,

see page 120.

Motor Information

Full Load Model

Max. HP Motor Torque Steel Adapter Size

Frame at Std. RPM in.lb. Plate ATD–

C210 40 / 2500 1,008 4-309-075-011-3

7-108-100-113-0

108 MB

C250 60 / 1750 2,161 4-309-075-005-3

7-108-100-113-0

108 MB

C280 100 / 1750 3,601 4-281-075-015-3

7-111-100-112-0

111 MB

C320 150 / 1750 5,402 4-281-075-016-3

7-111-100-112-0

111 MB

C360 200 / 1750 7,202 4-271-075-007-3

7-114-100-113-0

114 MB

Dimensions: inches

(Consult factory for drawing before final layout.)

Model No. of

Size ATD– A B C D Spuds E F

106 MB 5.44

8.75 8.81 1/4" NPT 2 2.00

2.00

206 MB 6.75 3.25

108 MB 5.82

12.12 11.13 1/2" NPT 2 2.13

1.50

208 MB 7.00 2.87

111 MB 6.38

16.00 14.75 1/2" NPT 2 3.02

2.00

211 MB 7.75 3.75

114 MB 7.75

18.75 17.50 1/2" NPT 2 3.88

2.25

214 MB 9.69 4.25

118 MB 9.01

23.25 22.00 1/2" NPT 3 4.75

2.75

218 MB 10.69 4.75

124H MB 9.26

30.00 29.00 1/2" NPT 3 8.25

3.13

224H MB 11.94 5.13

Wichita motor brakes typically produce more torque than is usually necessary.

Contact Wichita engineering for help in selecting the number of springs to produce the proper deceleration for your

application.

Note: For mounting, use socket head capscrews conforming to the ASTM-574-97a.

C-Face Motor Brakes