Power take-off clutches, Mechanical design, Design features – Wichita Clutch Mechanical Power Take-Offs User Manual

Page 2

Power Take-Off Clutches

146

Wichita Clutch 800-964-3262

P-1100-WC 1/12

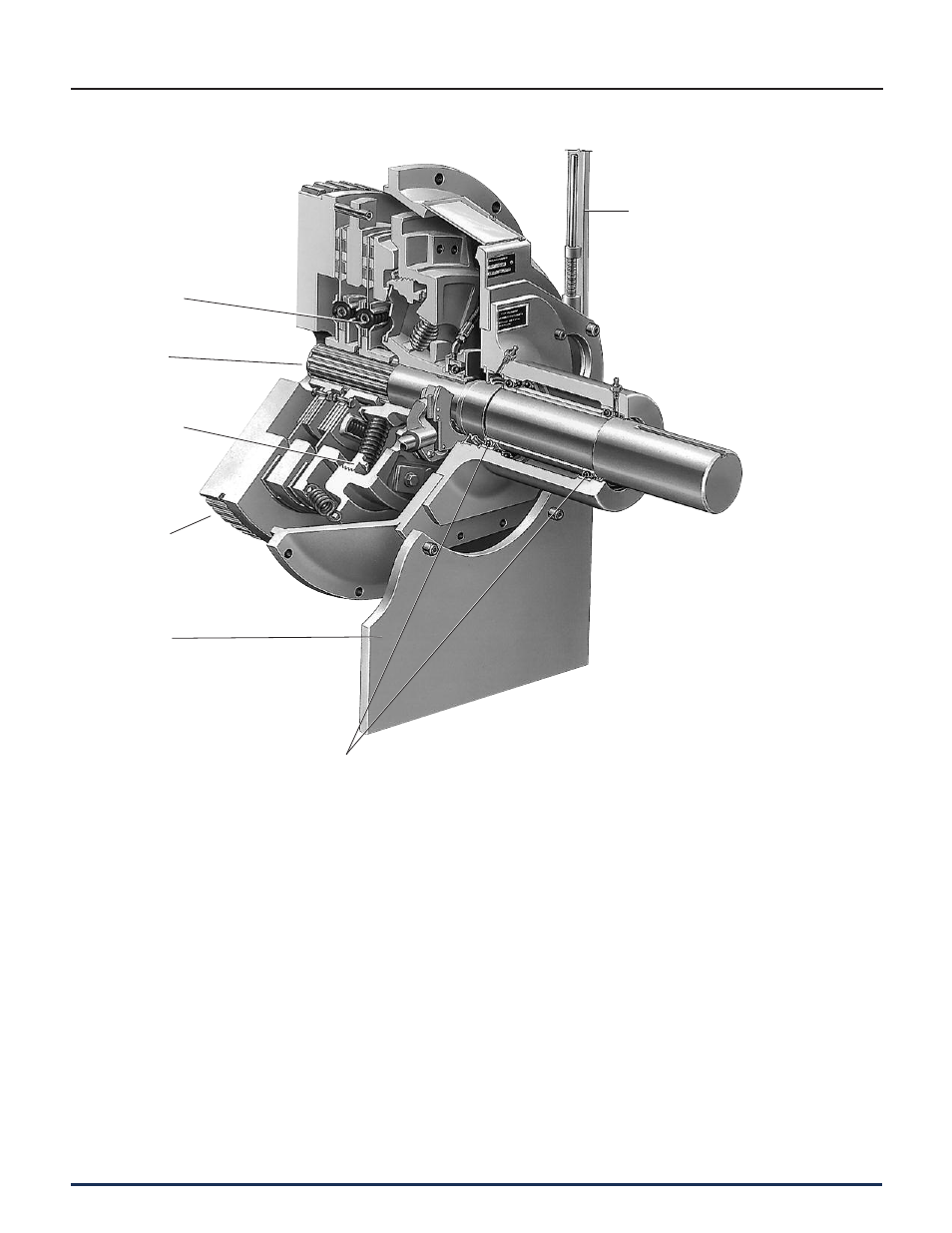

Shaft is supported

by ball bearings,

eliminating transmission

of damaging side loads.

Low hand lever effort.

30 lbs. vs. 100 lbs. for

over-center type PTO. Lever

can be mounted on either side

Optional

Support Base

In-Line

Design Features

•

Side Load version incorporates a rugged

cylindrical roller bearing system which

eliminates trouble-prone pilot bear ings.

Provides 100% external support of take-off

shaft. Prevents trans mis sion of side loads

that fatigue or even damage the engine

crankshaft.

•

Precise alignment ca pa bil i ties of the

bearing system ensure flywheel/clutch

concentricity to min i mize effects of diesel

engine torsional vibration.

•

Performance-proven Fuller Solo Spring

clutch provides easy engagement. Axial

load is provided by three pairs of springs

placed at an angle to the clutch centerline,

reducing required axial force as the clutch

is disengaged. The discs are raced with

trapezoidal ceramic buttons, and are

dampened with an assembly of coaxial

springs mount ed in the disc hub.

•

Dampened clutch discs prevent torsional

vibrations from damaging engine or

components.

•

Available in 2 sizes, from 14" to 15 1/2" for

engines up to 420 HP @ 2100 RPM.

Available with

dampened

driven discs

No pilot bearing

required

Adjustment free

feature

automatically

adjusts clutch

through

normal use

Ideal for

vehicular flywheel

applications

Mechanical Design