Standard vent clutches, Coupling and grinding mill clutches, Selection – Wichita Clutch SV - Standard Ventilated Clutch User Manual

Page 3: Selection example

Standard Vent Clutches

124

Wichita Clutch 800-964-3262

P-1100-WC 1/12

Selection

Clutch sizes are affected by the following

variables:

1. Machines that operate under smooth loads

require smaller clutches. These machines

are driven by either multi-cylinder high

speed engines or electric motors with

reduced starting current.

2. Drives that require high starting current

motors will require clutches with sufficient

torque to prevent excessive slipping while

starting.

3. Starting torque may be high, which

re quires fast clutch response time to

transmit the required torque or extended

clutch slip time to protect the prime mover.

4. Starting torques may be very low

com pared to the normal torque, which

may result in the clutch not being fully

pres sur ized prior to the time of torque

re quire ment. This will cause the clutch

to over-heat from slippage. Clutch inflation

time in this instance is very important.

5. Clutches on most machines are designed

to slip prior to damage from shockloads.

As a result, the clutch may require periodic

maintenance; therefore the clutch should

be located, for easy access, in the power

train. Clutches should also be located for

maximum cooling air. In instances where

this is not possible, forced air cooling may

be nec es sary for extended clutch life.

6. Safe operating speeds for clutches should

be maintained in design. The following

material specifications are rec om mend ed

for safe operation. The max i mum speeds

shown are safe op er at ing speeds based

upon years of Wichita experience.

Maximum Clutch

Contact Velocity FPM Material

6,000

(Recommended upper limit for slip)

cast iron

9,000 ductile iron

12,000 steel

These velocities are measured at the nominal

outside diameter of the clutch plates.

Selection Example

To properly select a clutch for your ap pli ca tion,

the following information is re quired:

1. Application horsepower

2. Re quired air pressure

3. Required torque

4. Clutch heat horsepower

5. Shaft diameter

Chart A (page 123) gives application re quire -

ments ranging from light duty (the A group) to

extra heavy duty (the D group). This chart will

give the initial se lec tion which is then compared

with the selection made using the Clutch Heat

Horsepower Chart B and the Clutch area (see

“lining area” column) in the Spec i fi ca tion Table

(Chart C, page 125-126).

Machine required:

Rock crusher (Grinding mill)

(Group D duty requirement)

WR

2

................................1,000 lb.ft.

2

RPM ..................................1,800

Clutch Slip Time ................6 sec.

HP......................................325 (diesel 8

............................................

cylinder)

Available air pressure ........120 PSI

Clutch must slip while bringing equipment

up to speed.

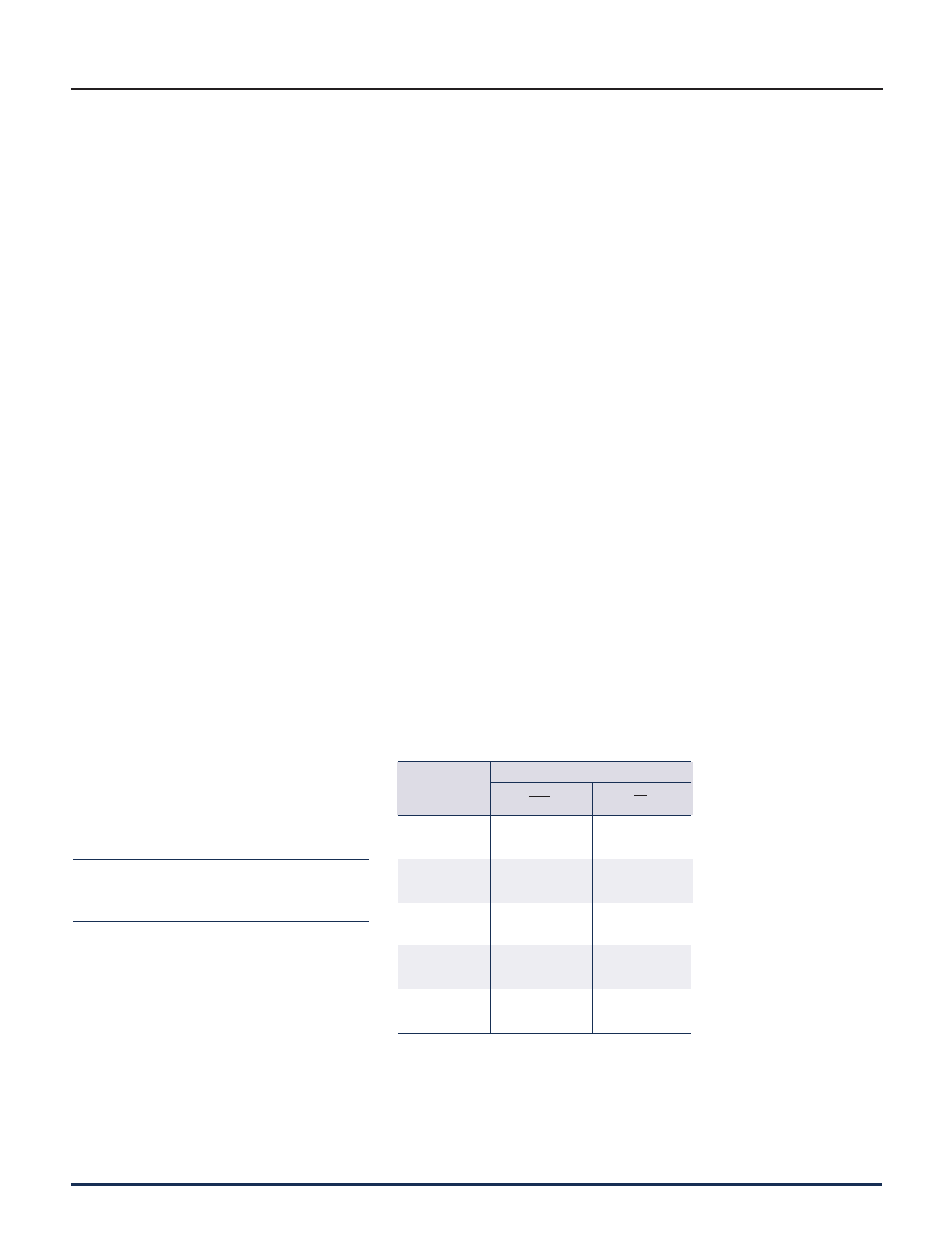

Chart B

Clutch heat horsepower absorption rate*

Slip

Time

Seconds

*

This chart is for use when clutch is at ambient temperature of 120°

F max.

HP

in.

2

ft.lb.

in.

2

Heat Input

Coupling and Grinding Mill Clutches

0 to 1 380 .7

2 617 .56

3 820 .5

4 1,000 .45

5 1,175 .43

6 1,330 .4

7 1,485 .38

8 1,630 .37

9 1,770 .36

10 1,900 .34