Rs-485 option, Valco instruments co. inc. vici ag international, Figure 4: control module, showing jumper locations – VICI Selectors (multiposition) Microelectric User Manual

Page 9: Figure 3: use of the offset feature

®

®

North America, South America, and Australia/Oceania contact:

Europe, Asia, and Africa contact:

Valco Instruments Co. Inc.

VICI AG International

Cheminert

®

and VICI

®

are registered trademarks of Valco Instruments Co. Inc. and VICI AG

P.O. Box 55603

Houston, TX 77255

Sales: (800) 367-8424

Tech: (713) 688-9345

Fax:

(713) 688-8106 [email protected]

Parkstrasse 2

CH-6214 Schenkon

Switzerland

Phone: +41 41 925 6200

Fax:

+41 41 925 6201 [email protected]

TN-415 10/14

JUMPERS 1 AND 2

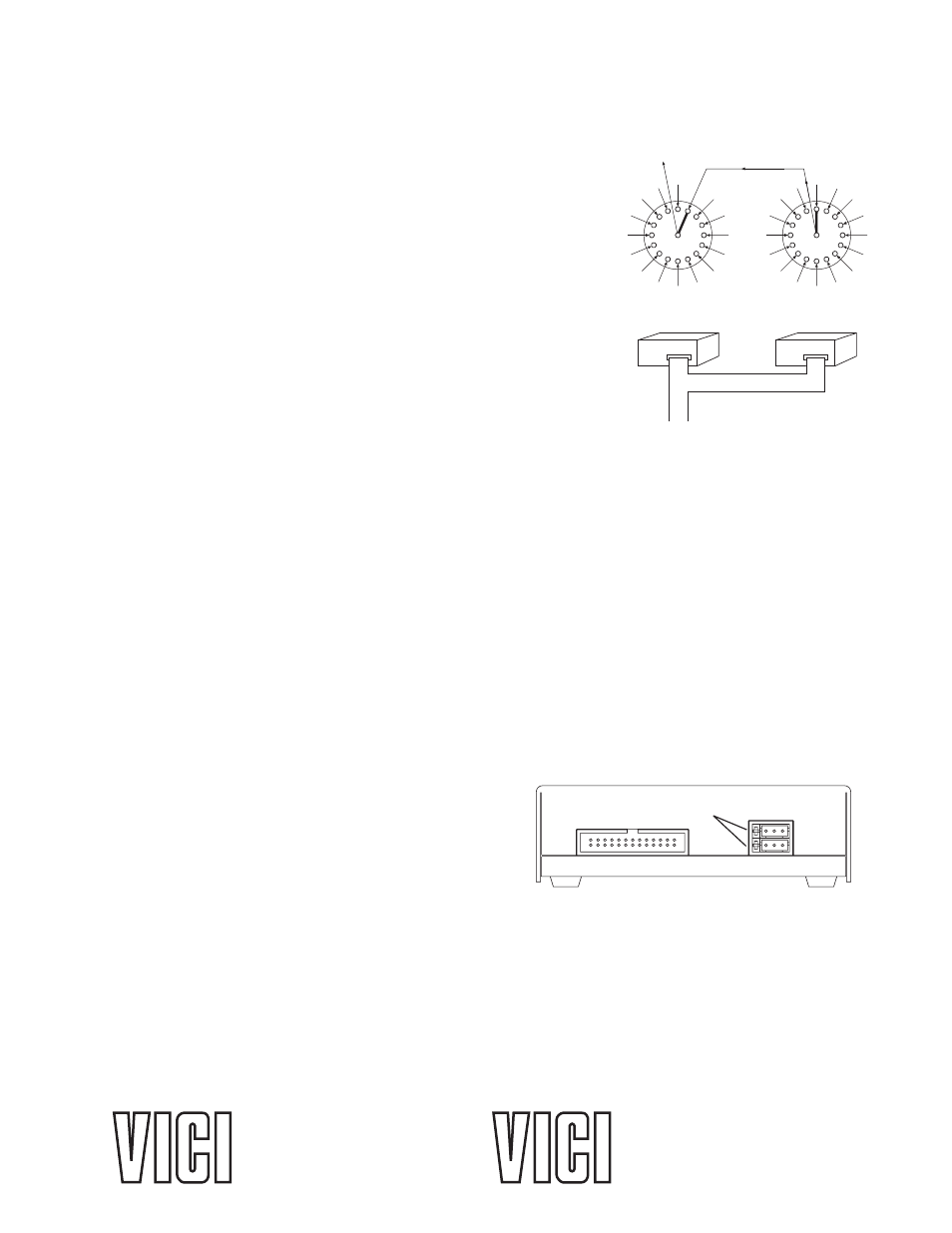

Figure 4: Control module,

showing jumper locations

the actuator will respond only to move commands for positions “10” through “19”. For any setting of

SO and NP, the lowest valid position will be the SO value and the highest valid position will be the SO

value plus the NP value minus 1; i.e., the actuator will respond to commands for position SO through

position {SO + NP - 1}.

Here is an example of how this can be used to set up a 31-stream

stream selection system using six dedicated BCD lines and two

16-position valves and actuators. First, use the serial port com-

mand “SL1” to enable the auto-latching feature on both actuators.

(This eliminates the need for a data latch signal.) Configure the

second actuator using the serial port command “SO16”, giving it a

valid position range of 16 to 31. Use a piece of tubing to connect

port 16 of the first valve (on the actuator with the SO value still at

the factory setting of “1”) to the common port of the valve on the

second actuator (which now has the SO set to “16”). Connect

streams 1 through 15 to ports 1 through 15 on the first valve, and

streams 16 through 31 to ports 1 through 15 on the second valve.

This system will step sequentially from 1 through 31 with a single

BCD instruction. However, when positions are selected in a random sequence, position 16 must always

be requested before any positions higher 16 are selected.

Figure 3 helps illustrate this: since both

actuators respond to a command to go to position 16, stream 16 will flow through valve 1/port 1, out

the common port of valve 2, into valve 1/port 16, and out of the common port of valve 1. Thereafter,

any stream select command that is above 16 will move only valve 2; when a move command for a

position less than 16 is given, valve 1 will move and cut off all flow from valve 2.

RS-485 Option

Software

The RS-485 option involves three minor software adaptations to the RS-232 protocol. The first is that the

ID range is extended to include the characters “A” through “Z”, with upper and lower cases treated as the

same ID. The second change is that the ID is required (either numbers from 0 to 9 or letters from A to

Z), and must be included in all commands. The factory-set default ID for all devices is “Z”. The third

adaptation is that all commands must include a forward slash [/] as the start-of-message character.

Hardware

The RS-485 hardware includes two 3-pin connectors

(

Figure 4) used as in/out connectors for easy daisy-

chaining of additional devices. Wired in parallel, the

signal assignments are as follows: Pin 1 is Ground,

Pin 2 is Phase B, and Pin 3 is Phase A.

The four male pins in a vertical row to the left of

these connectors are jumper headers, used to add or

remove terminating resistors from the communication lines. The top two and the bottom two should

be jumpered when termination is required. The RS-485 hardware specifications require termina-

tion at each end of the communication line, so in a daisy-chaining application the jumpers should be

removed from all the intermediate devices. The RS-485 port on the host computer or controlling device

generally includes terminating resistors, so only the actuator at the far end of the communication string

needs to have the jumpers installed.

S1

S4

S15

S16

OUTLET

VALVE 1

VALVE 2

CONTROL MODULE

FOR ACTUATOR 1

CONTROL MODULE

FOR ACTUATOR 2

PARALLEL CONTROL LINES

S19

S31

Figure 3: Use of the offset feature